Scanning target

A technology of scanning magnets and moving targets, applied in the field of scanning targets, can solve the problems of increasing ion beam current, reducing instantaneous and average temperature rise, transient temperature rise, etc., so as to increase ion beam current intensity and increase neutron production. Forehead, the effect of transient temperature rise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

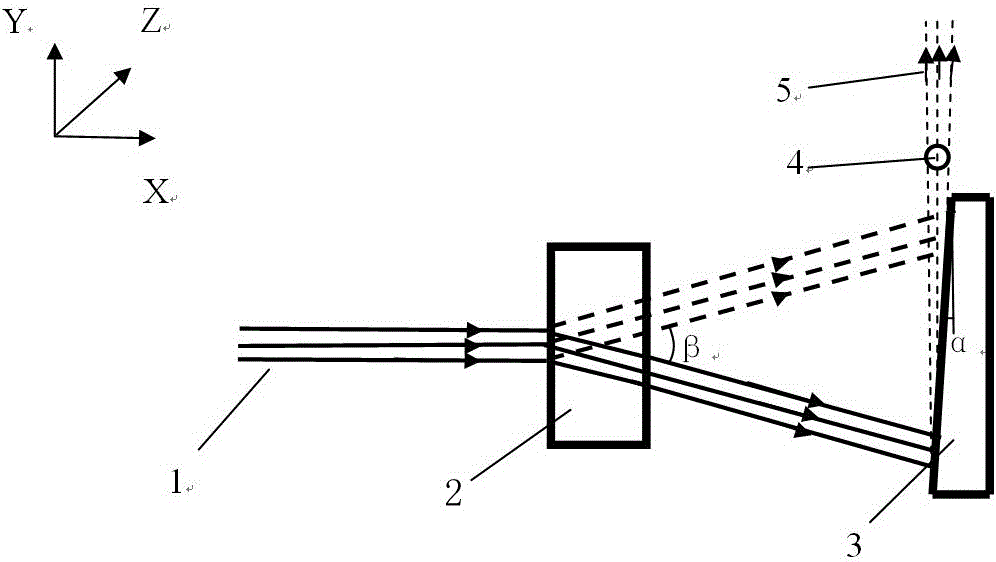

[0028] The ion beam energy of the original neutron generator system is 300keV, the current intensity is 12.5mA, the diameter of the beam spot is 15mm, the diameter of the rotating target is 200mm, the rotation speed is 1100 rpm, and the linear velocity of the bombardment area is 11.5m / s. The beam bombardment time is 0.87ms. Adopt the technology of the present invention to transform the neutron target of this system: scan the incident ion beam 1 evenly with the scanning magnet 2, expand it into a fan-shaped ion beam with a bottom length of 200mm, scan the expansion angle β to be -10°~10°, and fix the inclined plane of the target The inclination angle α ranges from 3° to 15°. In order to keep the moving speed of the beam spot on the target surface not lower than 11.5m / s, only the scanning frequency needs to be greater than 28.75Hz. Considering that the output of the 90-degree emission direction is slightly lower, and the neutron flux in the exit direction is reduced by about 10...

Embodiment 2

[0030] On the basis of Example 1, the scanning frequency is increased by about 15 times to reach 0.5kHz, the ion beam current intensity is increased by about 5 times to reach 70mA, the beam spot diameter remains unchanged, and the scanning width is expanded into a fan-shaped ion beam with a length of 400mm. The scanning expansion angle β is -20°~20°. Change the fixed target to a moving target 3, the inclination angle α of the moving target 3 ranges from 3° to 15°, and the moving target 3 translates back and forth within the range of ±50mm, and the transient temperature rise on the target surface is about lower than that of the original rotating target 6 times, and the average temperature rise is reduced by about 4 times. While effectively extending the target life, the neutron output is increased by 5 times.

Embodiment 3

[0032] The ion beam energy of the original neutron generator system is 380keV, the current intensity is 150mA, the beam spot diameter is 10mm, the rotating target diameter is 460mm, the rotation speed is 5000 rpm, the linear velocity of the bombardment area is 120m / s, and the beam current at each point The bombardment time was 0.083ms. Adopt the technology of the present invention to transform the neutron target of this system: use the scanning magnet 2 to uniformly scan and expand the incident ion beam 1 into a fan-shaped ion beam with a length of 200mm, the scanning expansion angle β is -30°~30°, and the inclined plane of the moving target 3 is inclined Angle α ranges from 3° to 15°. The moving speed of the beam spot on the target surface is not lower than 120m / s, and the scanning frequency is only required to be greater than 130Hz. Considering the slightly lower output in the 90-degree emission direction, the neutron flux in the emission direction is reduced by about 10%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com