Electromagnetic heating type hot-pressing and cold-pressing integrated multi-cavity laminating machine

An integrated lamination machine technology, applied in the manufacture of electrical components, printed circuits, multi-layer circuits, etc., can solve the problems of inability to do cold pressing process, large pressure error, large shrinkage ratio between the surface layer and the inner layer, etc., and achieve maintenance And low cost of maintenance and replacement, real-time and accurate temperature control, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

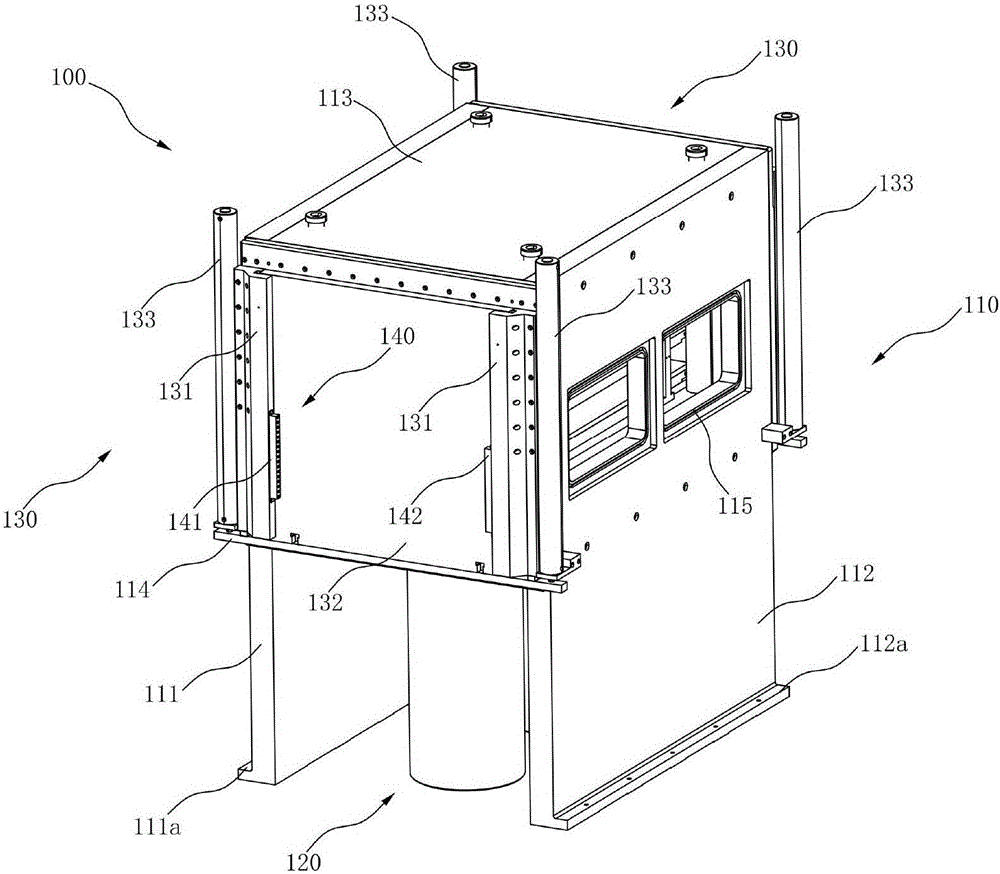

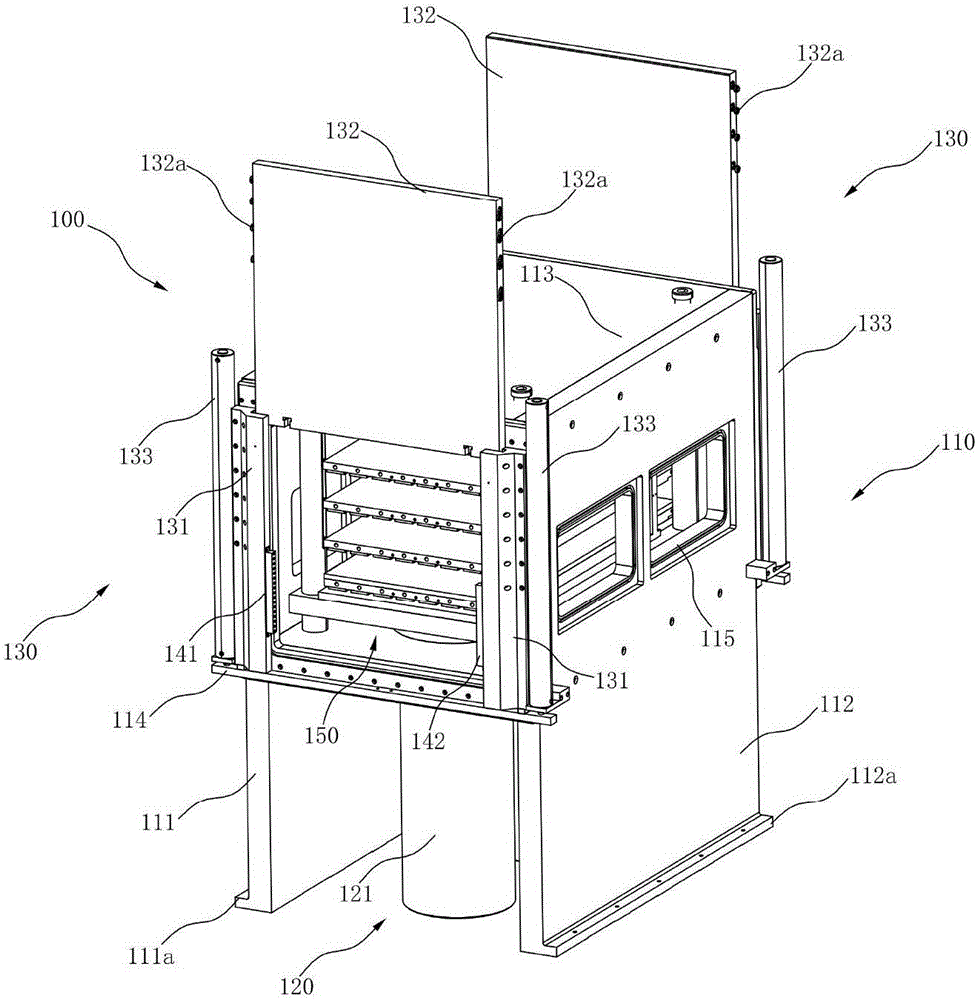

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings, and the aforementioned and other objects, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the description.

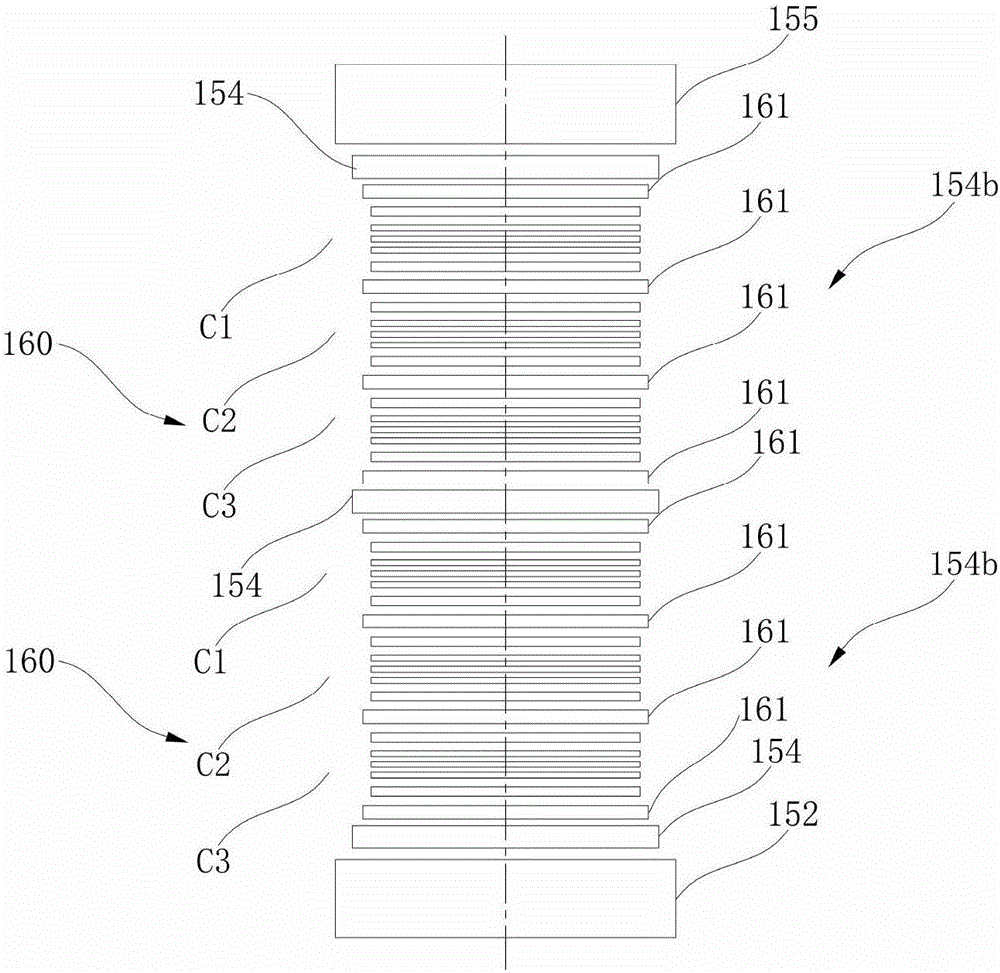

[0054] refer to figure 1 and Figure 20 According to the multi-cavity hot press 100 of the present invention, a PCB board package 160 to be pressed is placed in each pressing chamber 154b, and each PCB board package 160 to be pressed is formed by stacking at least one PCB board in sequence, in order To prevent the PCB boards from sticking during the pressing process, a thermally conductive and anti-stick partition 161 is provided between two adjacent PCB boards and between the PCB board and the pressing board 154 . In one embodiment, two press-fit chambers 154b are provided in the multi-chamber heat press 100, and a PCB package 160 to be pressed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com