Combined type VOCs (Volatile Organic Chemicals) purification and recovery device

A recovery device and combined technology, applied in the field of combined VOCs purification and recovery devices, can solve the problems of strict automatic control requirements, high operation requirements, and large number of equipment, achieving a high degree of automation, simplifying the process flow, and reducing the floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

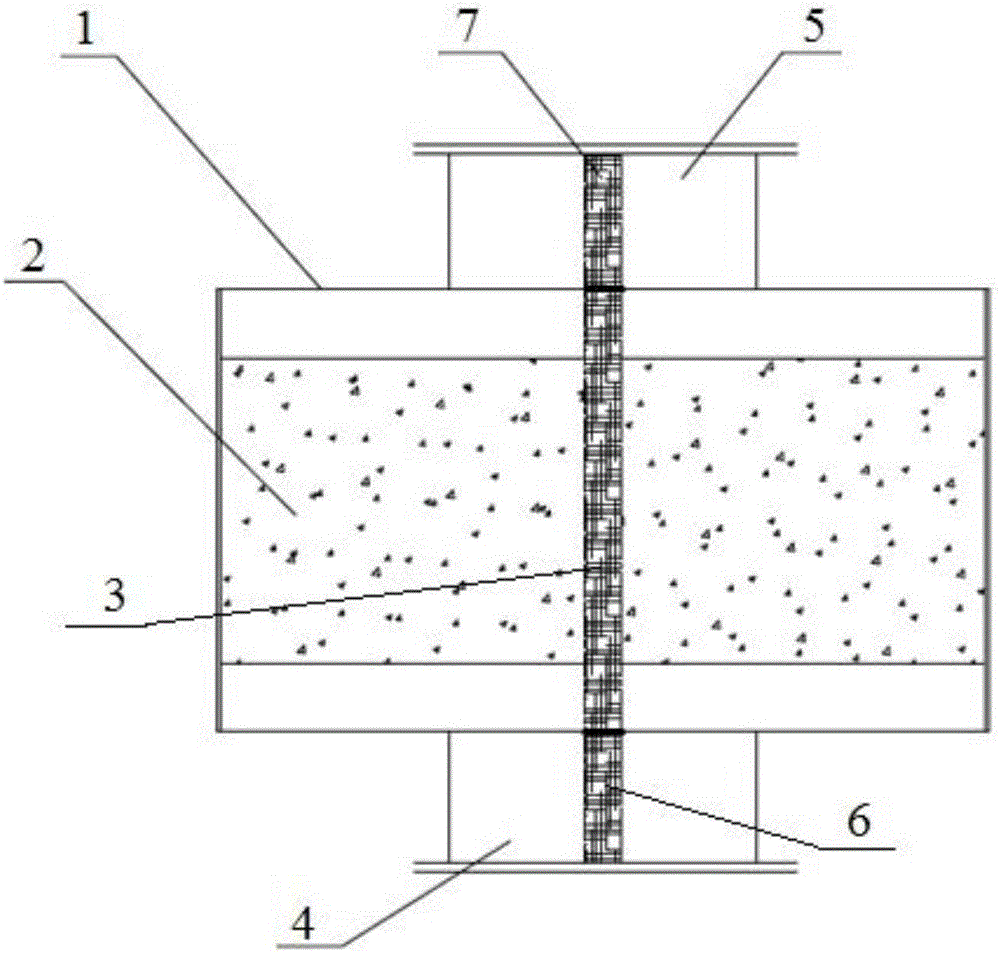

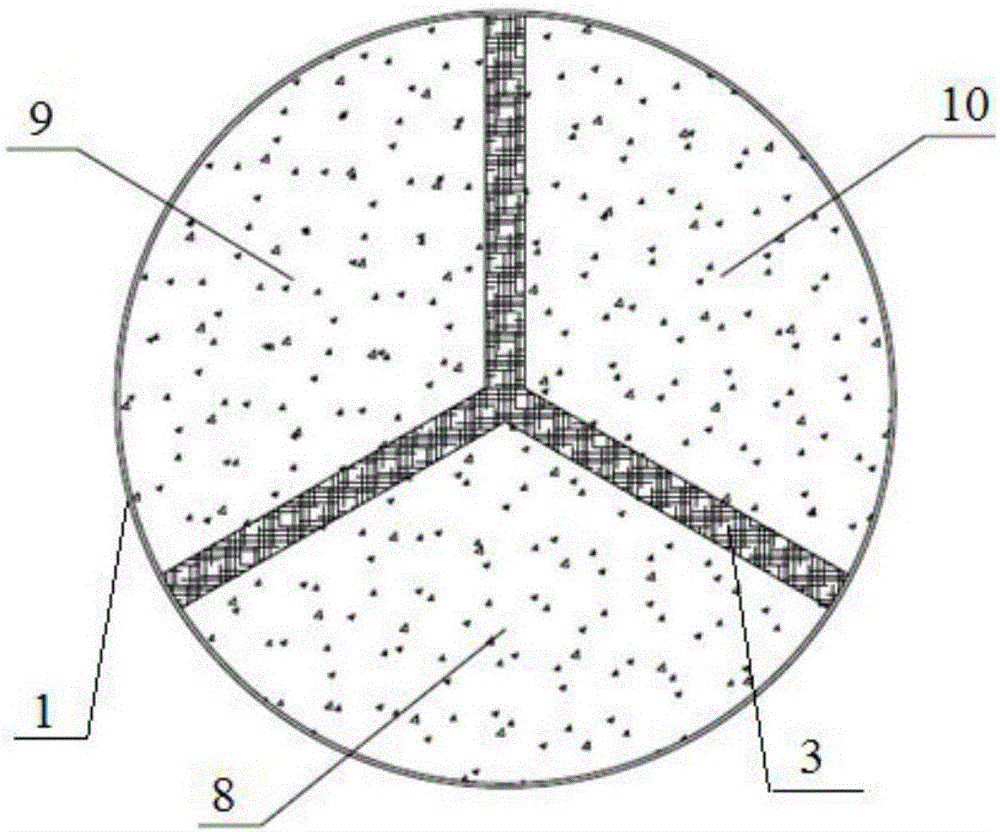

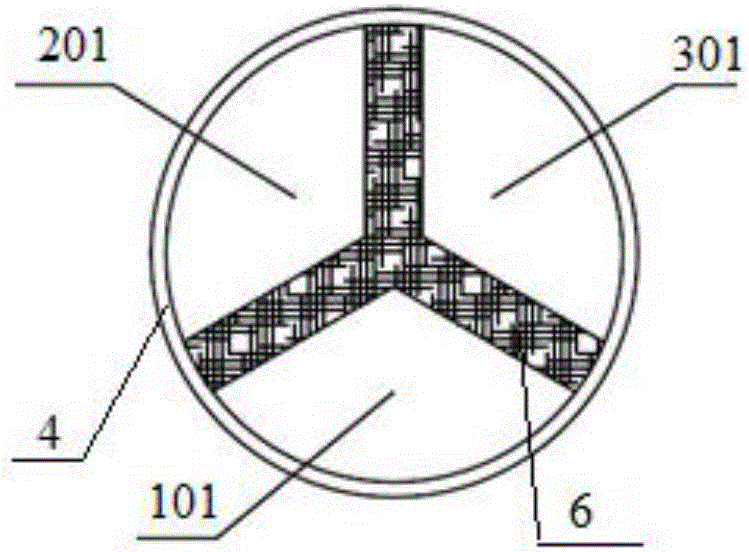

[0024] Specific examples, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a combined VOCs purification and recovery device includes an adsorption chamber, and the device includes a coaxially arranged shell 1 and a first heat insulation partition 3, and the first heat insulation partition 3 is vertically arranged on the shell 1 and separate the cavity in the housing 1 into at least two adsorption chambers. The first heat insulation partition 3 is a double-layer metal partition, and there is a heat insulation layer in the middle of the double-layer metal partition. The material of the heat insulation layer is composite Silicate, ceramic fiber, asbestos or aluminum silicate, the heat insulation layer is easy to obtain, low cost, good heat insulation effect, and can ensure that the temperature between adjacent adsorption chambers does not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com