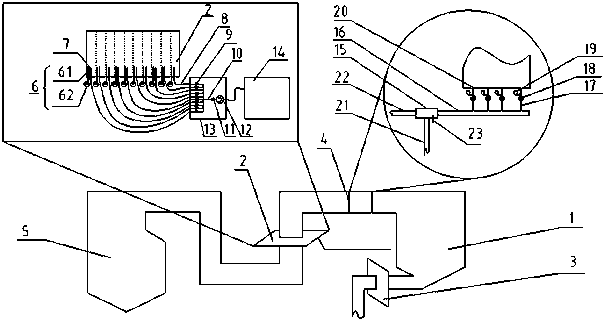

Intelligent optimization and adjustment system and method for ammonia injection grid of scr denitrification device

An ammonia injection grid, intelligent optimization technology, applied in the control/regulation system, chemical instruments and methods, separation methods, etc., can solve uneven, can not solve the ammonia injection of SCR denitrification system, can not know the flue concentration distribution To avoid insufficient or excessive adjustment, improve test efficiency and data validity, and improve technical and reliability effects

- Summary

- Abstract

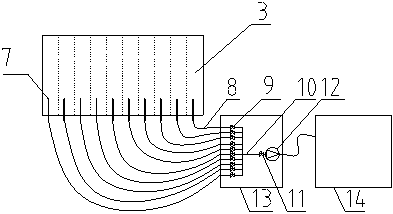

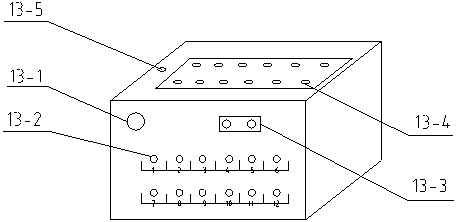

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The device and method of this embodiment are as described above, and will not be repeated. The optimization and adjustment test of ammonia injection under specific load conditions is carried out for a coal-fired power plant to ensure that the SCR outlet NO x The concentration distribution meets the uniformity requirement. Among them, the generator set is required to operate stably under a certain boiler load state, and the working conditions such as the output of the induced draft fan, the opening of the baffles at various places in the flue, the amount of coal supplied and the quality of the coal remain unchanged.

[0102] After entering the plant, the first step is to wait for the operating load and working conditions of the power plant to stabilize, and set the intelligent optimization and adjustment system of the ammonia injection grid of the SCR denitrification device in place. The flue gas flow distribution detection system, the flue gas distribution centralized s...

Embodiment 2

[0123] The device and method of this embodiment are as described above and will not be repeated. A coal-fired power plant implements an ammonia injection optimization adjustment test under multiple load conditions. It is required that after the ammonia injection optimization adjustment test, each ammonia injection branch pipe in the ammonia injection grid When the valves of the ammonia injection flow regulating valves 18 at 17 are kept stationary, the SCR outlet NO can still be guaranteed under the multi-load condition x The concentration distribution meets the uniformity requirement. Among them, it is required that during the optimization and adjustment test of ammonia injection, each load condition can run stably for more than one hour, and during the stable operation period, the output of the induced draft fan, the opening of the baffles around the flue, the amount of coal supplied and the quality of the coal should be maintained. The situation remains the same.

[0124] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com