Graphene electrode

A graphene and electrode technology, applied in the field of drilling electrodes or die electrodes, and wire electrodes, can solve the problems of arc wire damage, interference, short circuit, etc., and achieve the effect of reducing thermal resistance and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

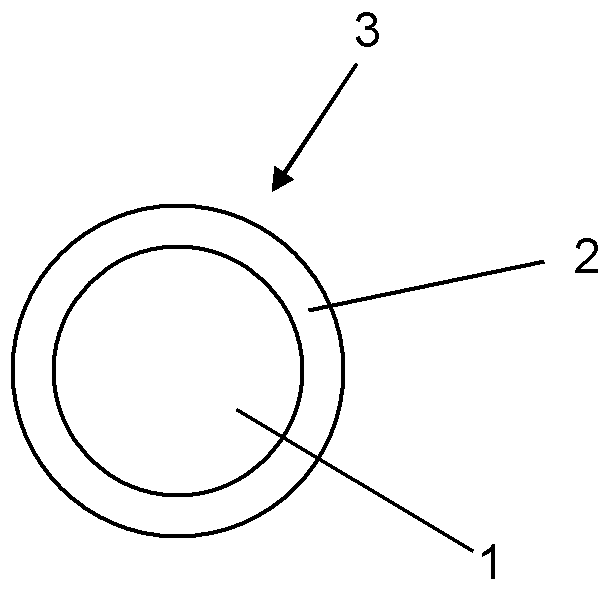

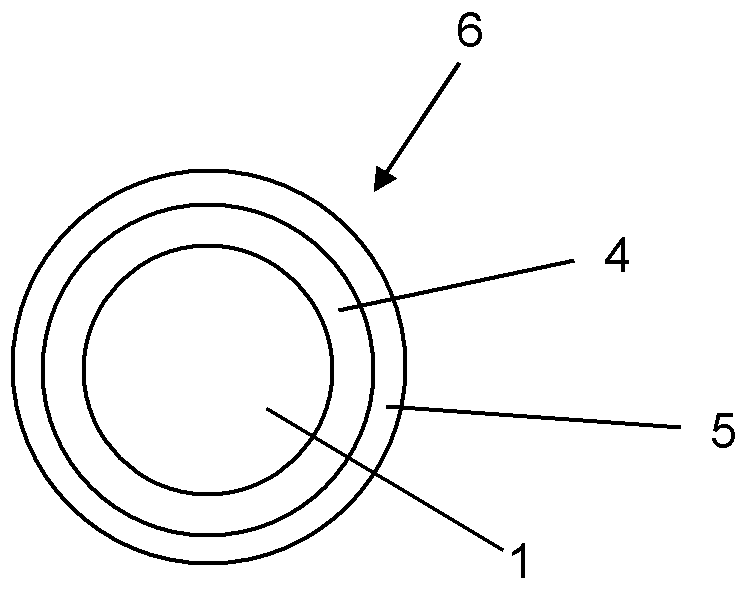

[0027] For embodiments of the invention, electrode cores made of copper, brass or steel will be covered with the inventive coating. Coatings can be synthesized or deposited on the core by using electrochemical processes. Like coatings made of zinc, zinc and graphene or copper and graphene, graphene coatings can be applied, for example, by such electrochemical processes.

[0028] Another possible embodiment of the invention is a copper or brass core with a first coating of a copper-zinc alloy with a higher zinc content than alpha brass, synthesized over the first coating using an electrochemical process Or deposit a graphene coating.

[0029] In an alternative embodiment, the copper or brass core is replaced by a steel core on which the graphene coating is synthesized or deposited using an electrochemical process. Alternatively, composites containing zinc and graphene or composites containing zinc, copper and graphene may be used as coating materials which are also deposited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com