Compact manipulator for 360-degree automatic welding of inductors

A compact, manipulator technology, applied in the field of manipulators, can solve the problems of complex manipulator structure, large space occupation, unfavorable mass use, etc., and achieve the effect of improving space adaptability, small space occupation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

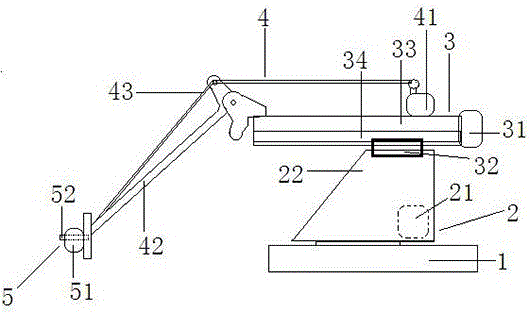

[0025] Place the inductor on the fixed seat 52, the left and right moving motor 21, the front and rear moving motor 31, the up and down moving motor 41, and the rotating motor 51 are connected to the controller, and the supporting cavity 22 on the base 1 is connected to the base 1 through the bearing. Connected, the left and right movement motor 21 located in the support cavity controls the support cavity 22 to perform circumferential rotation relative to the base 1, and the support cavity 22 drives the front and rear movement mechanism 3, the up and down movement mechanism 4, and the rotation mechanism connected thereto. 5 and then make a circumferential movement, so as to realize the left and right movement of the fixed seat 52; the present invention is provided with the left and right movement motor 21 in the support cavity 22, effectively moving the space occupied by the left and right movement motor 21, improving the space utilization rate, and reducing the manipulator vol...

Embodiment 2

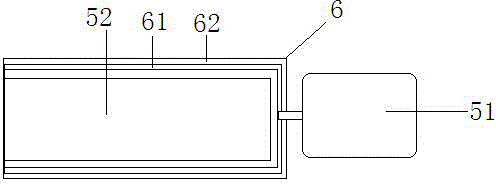

[0032] Such as figure 2 The protective layer 6 shown in the present invention is provided with a protective layer 6 on the surface of the fixing seat 52, and the protective layer 6 includes a temperature-insulating layer 61 and a corrosion-resistant layer 62 from bottom to top, and the temperature-insulating layer 61 is a composite silicon Salt heat insulation coating layer can effectively protect the fixed seat 52 under high temperature operation from high temperature infringement, and maintain the structural stability of the fixed seat 52; the corrosion-resistant layer 62 is polyamide resin, which can effectively ensure that the fixed seat 52 avoids The erosion of the surface of the fixing seat 52 by high-temperature tin material, rosin, etc. effectively prolongs the service life of the fixing seat 52 by 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com