A high-speed intelligent cutting machine for chip electronic components

A technology of electronic components and cutting machines, applied in the direction of work accessories, manufacturing tools, stone processing equipment, etc., can solve the problem that there is no function of auto focus, automatic search for block marking points, and the camera does not have automatic adjustment and auto focus functions. High cutting accuracy and other issues, to achieve the effect of high consistency, high positioning accuracy, and small cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

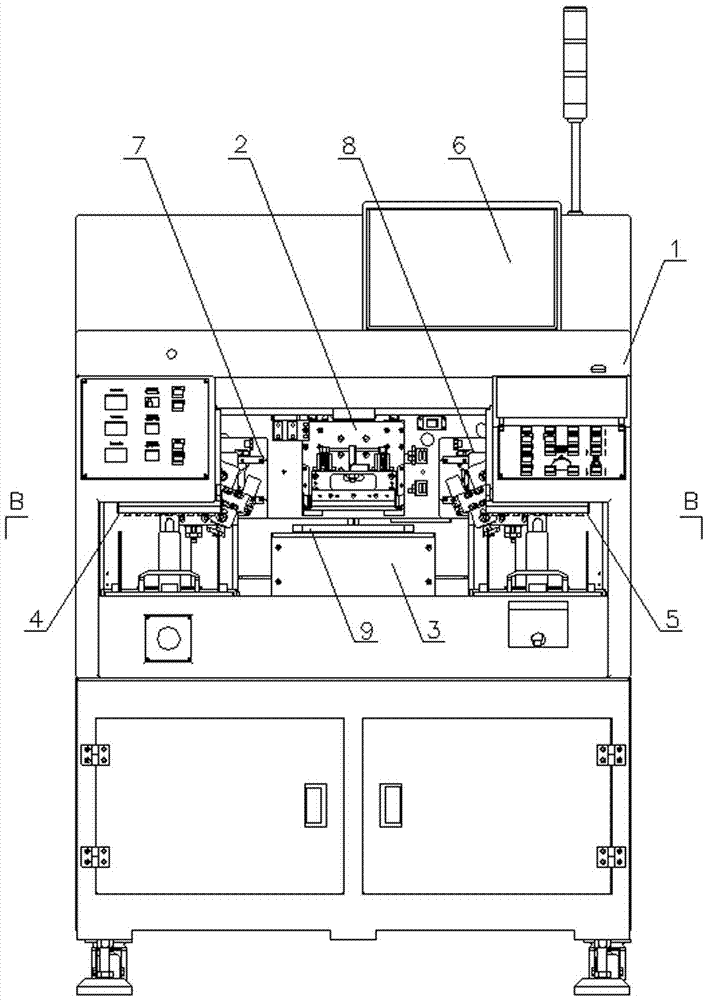

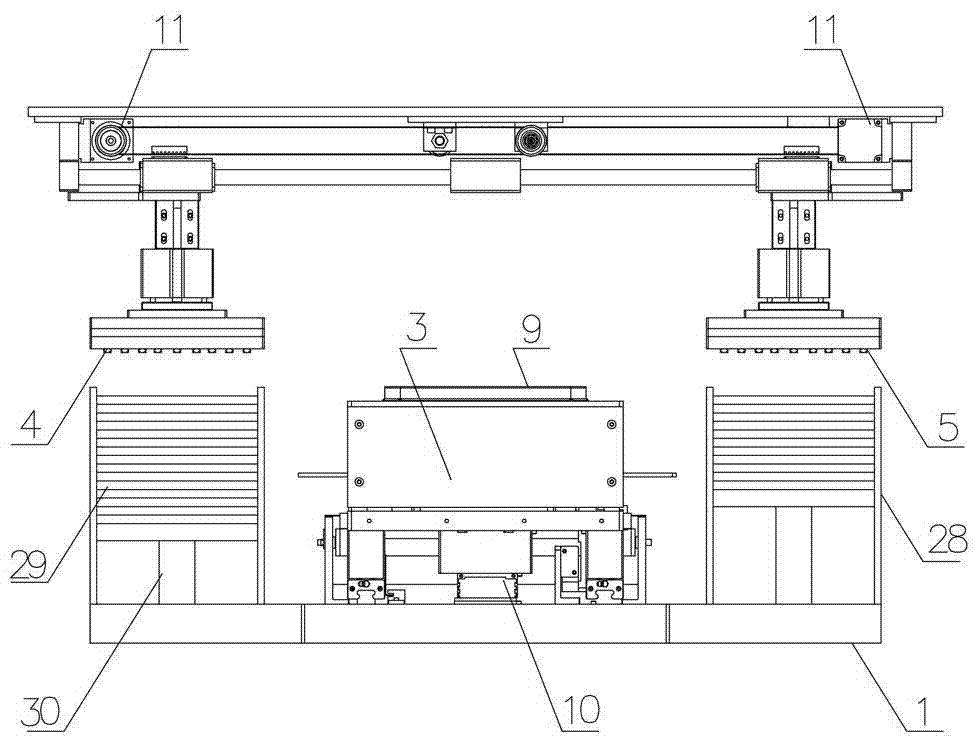

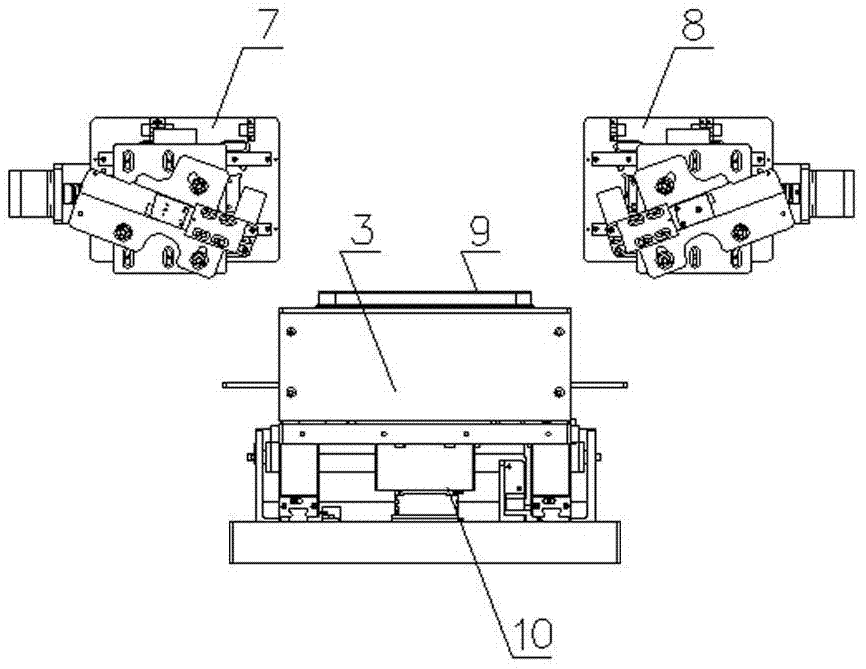

[0054] figure 1 It is a schematic diagram of a high-speed intelligent cutting machine for chip electronic components. Including the body structure 1, carrier 9, detection and positioning mechanism, cutting mechanism 2, control system, and operation panel 6, a vacuum channel is provided inside the carrier 9, and a feeding and receiving mechanism 5 is set above the left and right sides of the carrier 9 ,See figure 2 , the feeding and receiving mechanism 5 is provided with a vacuum suction cup and a feeding and receiving transmission motor, below the vacuum suction cup, a bar block warehouse for accessing the bar block 29 is set, and in the body structure 1 at the bottom of the bar block storehouse, there is a The electric ejector rod 30 of bar block 29 displacements up and down, see Figure 4 , 5 , the lower part of the carrier 9 is connected to the carrier plate 3, and at the junction of the carrier 9 and the carrier 3, there is a DD direct drive servo rotation mechanism 33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com