Low-density rock expanded AN explosive and preparation method thereof

A rock-expanded ammonium nitrate and low-density technology, which is applied in the direction of explosives, can solve the problems affecting the fluidity of explosives and the viscosity of the oil phase, and achieve the effects of enhanced moisture-proof and anti-caking capabilities, good thermoplasticity, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

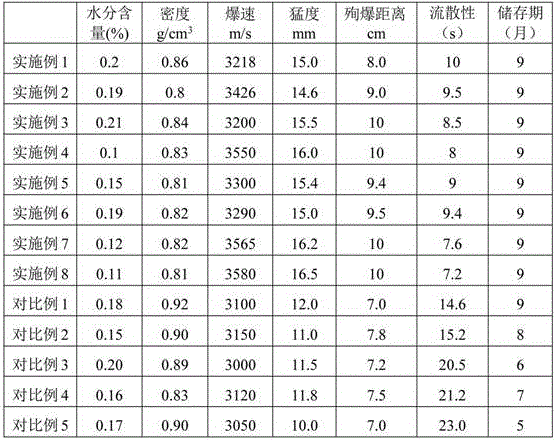

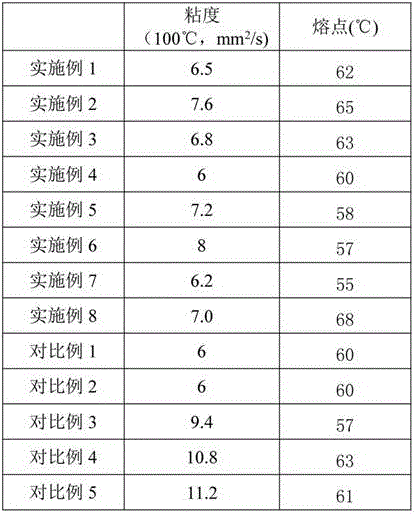

Examples

Embodiment 1

[0025] A low-density rock expanded ammonium nitrate explosive, comprising the following raw materials by weight percentage: 90% ammonium nitrate, 0.1% dispersant NNO, 5% wood powder, 1.6% perlite, 3% oil phase, and 0.1% octadecylamine , 0.2% stearic acid; wherein the particle size of wood flour is 50 mesh, the particle size of perlite is 40 mesh, and the particle size of ammonium nitrate is 50 mesh.

[0026] Wherein the oil phase is prepared from the following raw materials by weight percentage: 28% of No. 56 paraffin, 45% of composite wax, and 27% of microcrystalline wax.

[0027] The oil phase is prepared by the following steps: put No. 56 paraffin wax, composite wax and microcrystalline wax in a dissolving tank, heat it with steam until the temperature of the dissolving tank is 85°C, and stir until No. 56 paraffin wax, composite wax and microcrystalline wax are completely melted , that is, the oil phase is prepared.

[0028] A preparation method of low-density rock expande...

Embodiment 2

[0033] A low-density rock expanded ammonium nitrate explosive, comprising the following raw materials by weight percentage: 91% ammonium nitrate, 0.2% sodium lignosulfonate, 4.5% wood powder, 2% perlite, 2% oil phase, octadecylamine 0.15%, stearic acid 0.15%; the particle size of wood powder is 60 mesh, the particle size of perlite is 45 mesh, and the particle size of ammonium nitrate is 60 mesh.

[0034] Wherein the oil phase is prepared from the following raw materials by weight percentage: 29% of No. 58 paraffin, 41% of composite wax, and 30% of microcrystalline wax.

[0035] The oil phase is prepared by the following steps: put No. 58 paraffin wax, composite wax and microcrystalline wax in a dissolving tank, heat it with steam until the temperature of the dissolving tank is 80°C, and stir until No. 58 paraffin wax, composite wax and microcrystalline wax are completely melted , that is, the oil phase is prepared.

[0036] A preparation method of low-density rock expanded a...

Embodiment 3

[0041] A low-density rock expanded ammonium nitrate explosive, comprising the following raw materials by weight percentage: 91.5% ammonium nitrate, 0.3% dispersant CNF, 2% wood flour, 1% perlite, 5% oil phase, and 0.1% octadecylamine , stearic acid 0.1%; wherein the particle size of wood flour is 70 mesh, the particle size of perlite is 50 mesh, and the particle size of ammonium nitrate is 70 mesh.

[0042] Wherein the oil phase is prepared from the following raw materials by weight percentage: No. 60 paraffin wax 28.5%, composite wax 39.5%, microcrystalline wax 32%.

[0043] The oil phase is prepared by the following steps: put No. 60 paraffin wax, composite wax and microcrystalline wax in a dissolving tank, heat it with steam until the temperature of the dissolving tank is 90°C, and stir until No. 60 paraffin wax, composite wax and microcrystalline wax are completely melted , that is, the oil phase is prepared.

[0044] A preparation method of low-density rock expanded ammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com