Reagent for preventing silver of LED silver bracket from discoloring and preparation and film forming methods

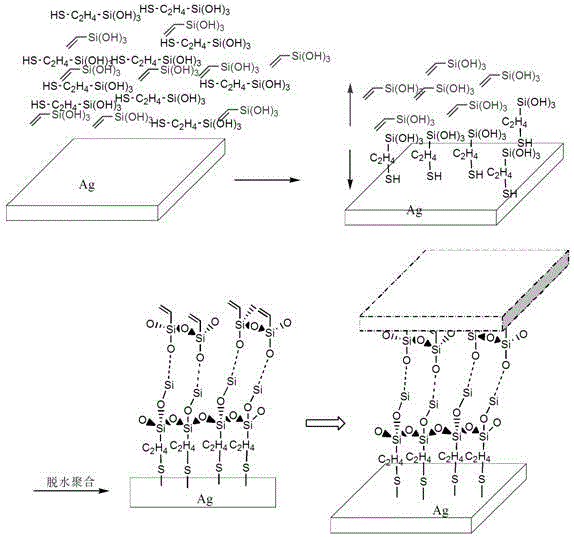

A film-forming method and color-changing agent technology, which can be used in the coating process of metal materials, electrical components, circuits, etc., can solve the problem that the discoloration of the silver substrate cannot be completely eliminated, the gas barrier property of the encapsulated molecules is not strong, and the synthesis process of polysilazane Complicated and other issues, to achieve the effect of being suitable for large-scale promotion, not affecting the later packaging process, and tightly combined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Preparation of component A of anti-silver discoloration agent for LED silver bracket: Take 40mL ethanol in a 100mL beaker, add dropwise 3.5mL deionized water, 1.6mL acetic acid, shake well, then add 0.7mL 3-mercaptopropyltriethoxysilane, stir (room temperature, medium speed) 18 hours. You can drop a drop of the solution on a glass slide and dry it in an oven at 100°C. If it is a transparent glass body, it can be used. After preparation, store at room temperature at 15°C until use. The solution is A1.

[0042] Preparation of component B of anti-silver discoloration agent for LED silver bracket: Take 4mL of ethanol in a 20mL vial, add 3mL of deionized water and 1.2mL of vinyl tris(2-methoxyethoxy)silane dropwise into it, and let it stand for 24 hours. After preparation, store at room temperature (15°C) for later use. The solution is B1.

Embodiment 2

[0044] Preparation of component A of anti-silver discoloration agent for LED silver bracket: Take 40mL of ethanol in a 100mL beaker, add dropwise 5mL of deionized water, 2.5mL of acetic acid, shake well, then add 1.0mL of 3-mercaptopropyltriethoxysilane, stir ( room temperature, medium speed) for 20 hours. You can drop a drop of the solution on a glass slide and dry it in an oven at 150°C. If it is a transparent glass body, it can be used. After preparation, store at room temperature at 25°C until use. The solution is A2.

[0045] Preparation of component B of anti-silver discoloration agent for LED silver bracket: Take 4mL of ethanol in a 20mL vial, add dropwise 3mL of deionized water, 1.2mL of vinyl tris(2-methoxyethoxy)silane, and let it stand for 24h. After preparation, store at room temperature at 25°C until use. The solution is B2.

Embodiment 3

[0047] Preparation of component A of anti-silver discoloration agent for LED silver bracket: Take 40mL of methanol in a 100mL beaker, add dropwise 5mL of deionized water, 1.6mL of formic acid, shake well, then add 1.0mL of 3-mercaptopropyltrimethoxysilane, stir (room temperature , medium speed) for 24 hours. It can be taken by taking a drop of the solution and dropping it on a glass slide, and drying it in a 100°C oven. If there is a transparent glass body, it can be used. After preparation, store at room temperature at 20°C until use. The solution is A3.

[0048] Preparation of component B of anti-silver discoloration agent for LED silver bracket: Take 4mL of ethanol in a small bottle, add 3mL of deionized water, 0.6mL of acetic acid, and 1.2mL of vinyltriethoxysilane dropwise into the vial, and let it stand for 24 hours. After preparation, store at room temperature at 20°C until use. The solution is B3.

[0049] 2. Preparation of anti-silver discoloration agent for LED s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com