Wind power generator blade, wind power generator cooling device and wind power generator unit

A technology for wind turbines and heat sinks, applied in the fields of wind turbines, wind turbine blades, and wind turbine heat sinks, can solve the problem of reducing the stability and reliability of wind turbines, increasing the cost and energy consumption of wind turbines, Affecting the heat dissipation effect of wind turbines and other issues, to achieve the effect of reducing weight, improving heat dissipation efficiency, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

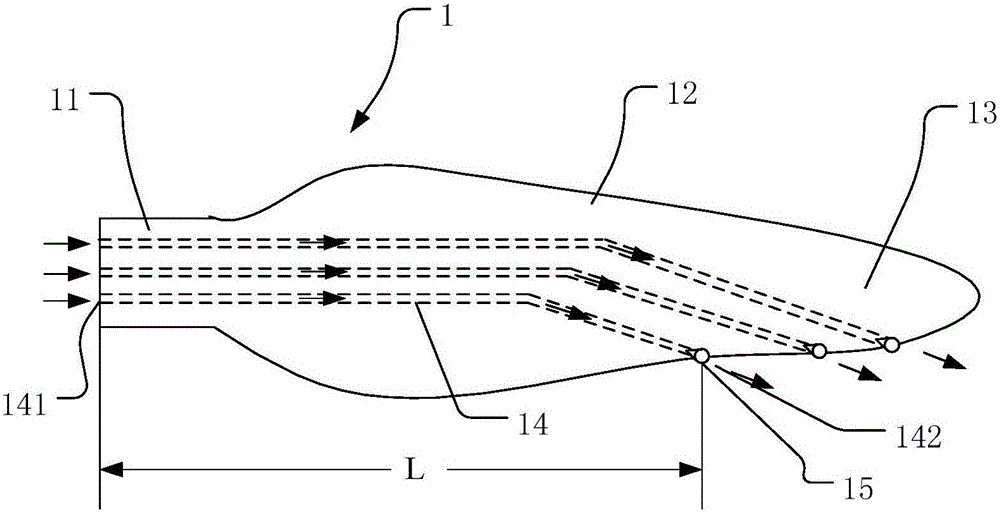

[0042] figure 1 It shows the wind power generator blade 1 according to Embodiment 1 of the present invention, including the blade root 11 and the blade main body 12; it also includes: the air inlet 141, which is arranged at the blade root 11; the air outlet 142, which is arranged at the blade The outer surface of the main body 12 ; the blade air channel 14 is arranged inside the wind turbine blade 1 and communicates with the air inlet 141 and the air outlet 142 ; the anti-backflow mechanism 15 is arranged at the air outlet 142 .

[0043]The wind power generator blade 1 provided in Embodiment 1, by setting the blade air channel 14 inside and the air outlet 142 on the outer surface, when the wind power generator blade 1 rotates with the hub 2, between the air inlet 141 and the air outlet 142 Forming an air pressure difference (the specific principle of forming an air pressure difference will be described in Embodiment 2 in conjunction with the cooling device of the wind power ge...

Embodiment 2

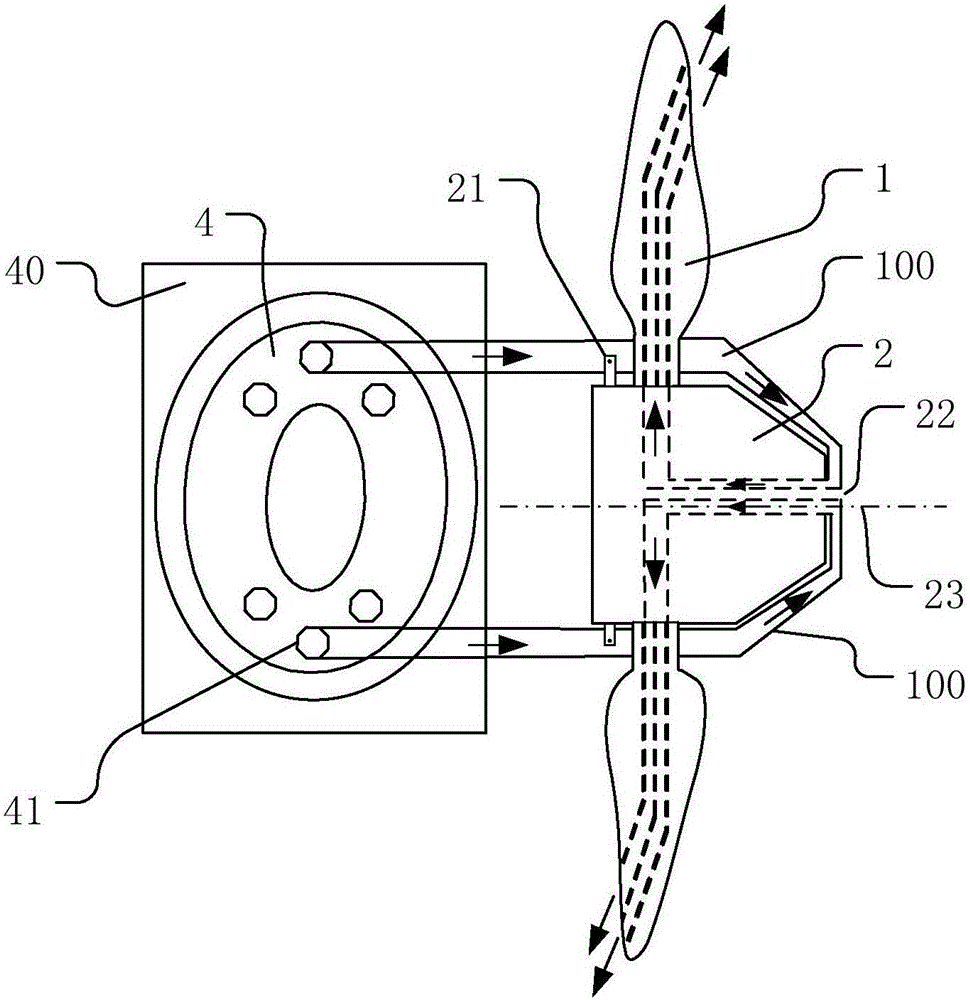

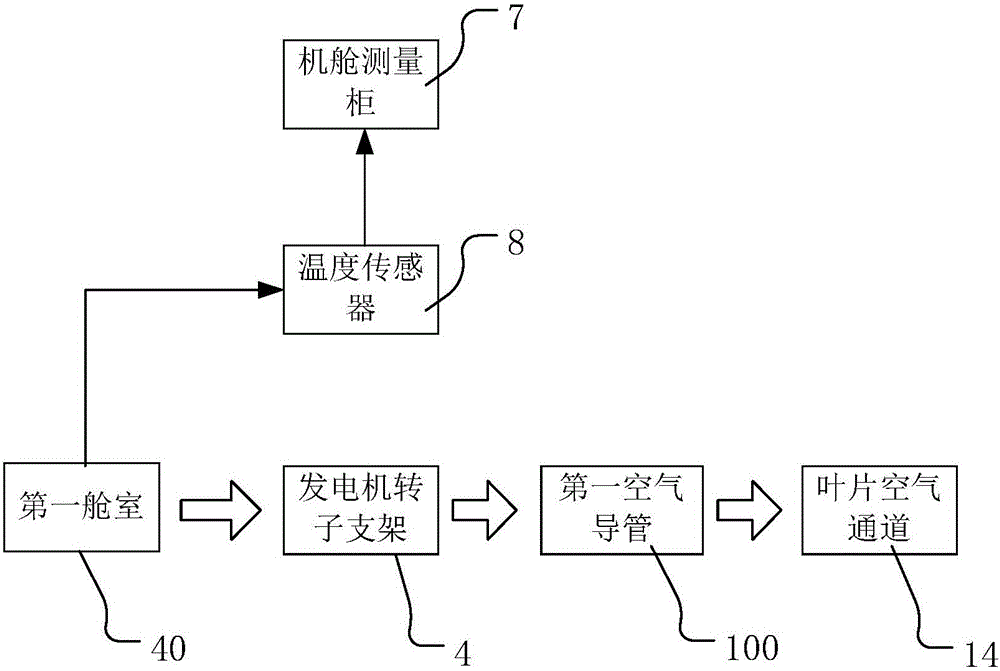

[0052] figure 2 and image 3 The structural diagram and principle diagram of the cooling device for wind power generators in the second embodiment are shown.

[0053] The heat dissipation device of the wind power generator in the second embodiment includes a cabin for accommodating heating elements, a hub 2 , the blade 1 of the wind power generator as described in the first embodiment, and a cooling channel. Wherein, the blade 1 is fixedly connected with the hub 2 ; the cooling channel connects the cabin and the air inlet 141 of the wind turbine blade 1 .

[0054] The cabin in this embodiment refers to the cabin that is arranged in the wind power generator and accommodates heating elements that generate heat during operation. For example, the cabin can be the inner cavity of the generator or a cabin for accommodating switch cabinets or current cabinets, etc., but it is not limited to the above cabins. Any cabin that needs heat dissipation in the wind generator is within the...

Embodiment 3

[0094] Figure 4 and Figure 5 It is a structural diagram and a schematic diagram of a heat dissipation device for a wind power generator according to Embodiment 3 of the present invention. The difference between the cooling device for wind-driven generators in Embodiment 3 and the embodiment of dissipating heat for the first compartment 40 in Embodiment 2 is that the cooling device for wind-driven generators in Embodiment 3 can be a second compartment 50 different from the first compartment 40 Heat dissipation. The second compartment 50 may be a compartment for accommodating a converter or a main control switchgear, but is not limited to the above-mentioned compartments, and may also be other compartments different from the first compartment 40 and requiring heat dissipation.

[0095] Specifically, the difference between the second compartment 50 and the first compartment 40 is that the first compartment 40 is the inner chamber of the generator, and the first compartment 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com