Method and system for evaluating ageing life of crosslinked polyethylene insulating cable for smart energy

A technology for cross-linked polyethylene and insulated cables, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate aging life of cross-linked polyethylene insulated cables, aging failure of cross-linked polyethylene insulation, etc., and achieve the reduction of test Effects of Result Error, Accuracy Improvement, and Evaluation Error Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

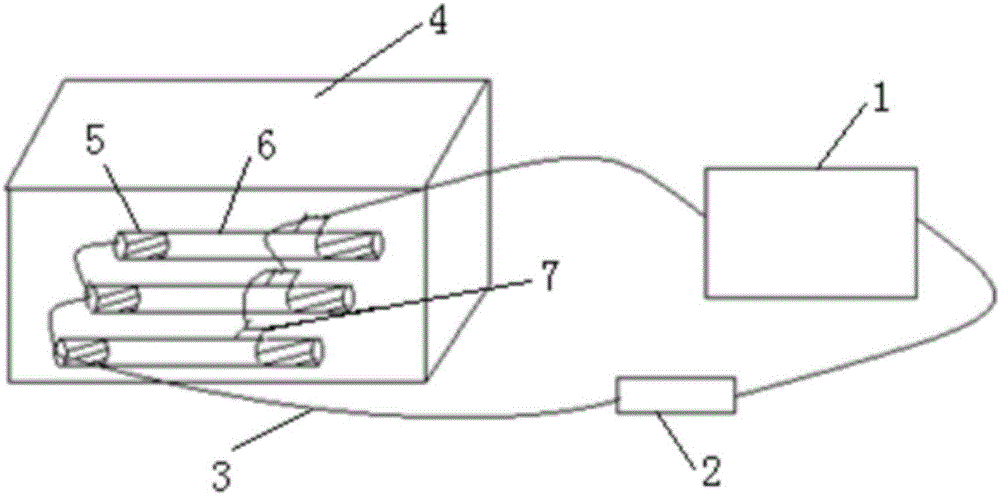

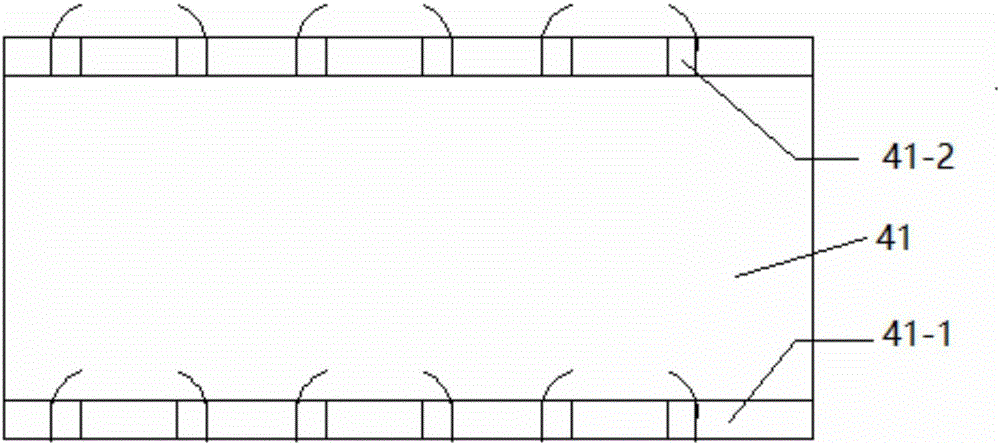

[0032] See figure 1 , figure 2 with image 3 , the aging life evaluation system of cross-linked polyethylene insulated cables for smart energy in this embodiment includes an AC power supply 1, a line resistance 2, a high temperature resistant power supply connection line 3 and an air aging oven 4; a sample holder 41 is arranged in the air aging oven 4; The sample holder 41 includes a slot 41-1 and a sliding fixture 41-2 slidably fixed in the slot 41-1. Epoxy resin shields are arranged around the inner wall of the air aging oven 4 .

[0033] The aging life assessment method includes the following steps:

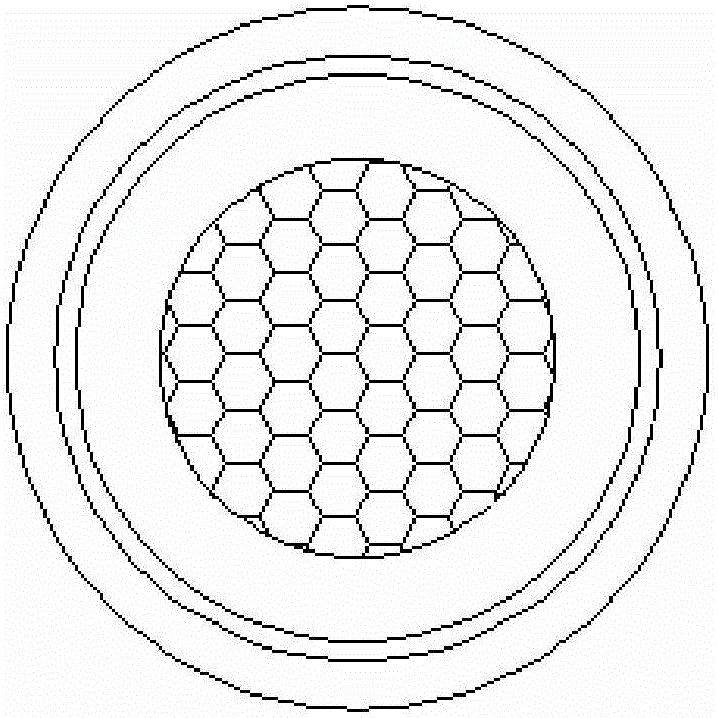

[0034] Step 1: For the single-core cable sample to be evaluated (structure such as image 3 shown) for pretreatment, peel off the outer sheath at one end of the cable, adjust the sliding clamp according to the outer diameter of the cable sample, fix the processed cable sample on the sample holder 41, and fix 3 samples to be evaluated on each sample holder 41 Cable sample...

Embodiment 2

[0039] See Figure 4 with Figure 5 , a method of this embodiment is basically the same as that of embodiment 1, the difference is: as Figure 5 As shown, the cable sample to be evaluated is a three-core cable.

[0040] In Step 1, two cable samples to be evaluated are fixed on each sample holder 41 .

[0041] In step 2, metal copper wires are used in advance to connect the three conductors 5 of each cable sample to be evaluated together, and then the AC power supply is connected, and any metal shielding layer on the three insulated cores of the cable sample to be evaluated is selected to be grounded. The three conductors 5 and the metal shielding layer 7 are respectively connected in parallel by using high temperature resistant connecting wires 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com