Fluorescent microsphere supported optical material and preparation method thereof

A technology of fluorescent microspheres and optical materials, applied in the field of optical testing materials, can solve the problem that biochips are not mentioned in relevant literature, and achieve the effect of significant reference significance, suitable spacing, and correcting imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

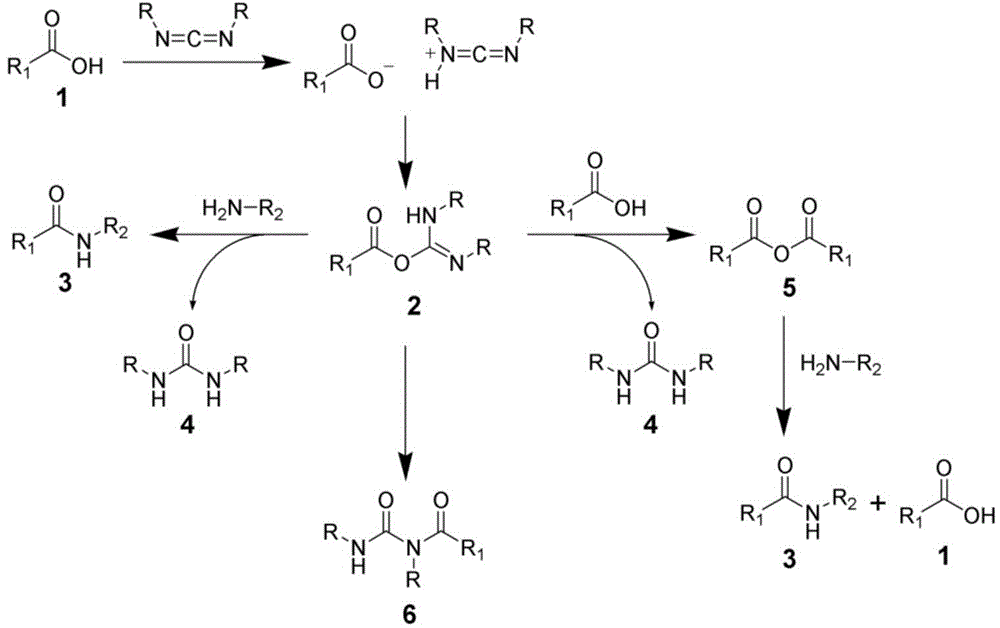

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, preparation of optical material loaded with fluorescent microspheres

[0035] (1) Rinse the silicon-based chip with 50 μL of 50 mM phosphate buffer solution and 50 μL of 50 mM sodium hydroxide aqueous solution in sequence, incubate for 20 min while rinsing with aqueous sodium hydroxide solution, and then wash the silicon-based chip with 50 μL of 50 mM phosphate buffer solution to make the silicon-based chip There are positively charged amino groups on the surface of the chip;

[0036] (2) 2-(N-morpholine) ethanesulfonic acid solution of 3 mg / mL 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide with a volume ratio of 10:1 and Carboxylated fluorescent microspheres (F-8809, with a wavelength of 530nm and a diameter of 0.2μm) were mixed uniformly by shaking for 5s and centrifuging for 5s in turn to obtain a mixture;

[0037] (3) Rinse the silicon-based chip treated in step (1) with the mixed solution, bond at 21° C. for 30 min, and rinse with 50 mM phosphate buff...

Embodiment 2

[0044] Embodiment 2, preparation of optical material loaded with fluorescent microspheres

[0045] The preparation method is the same as that in Example 1, except that the silicon-based chip is replaced by a glass chip (ordinary glass sheet).

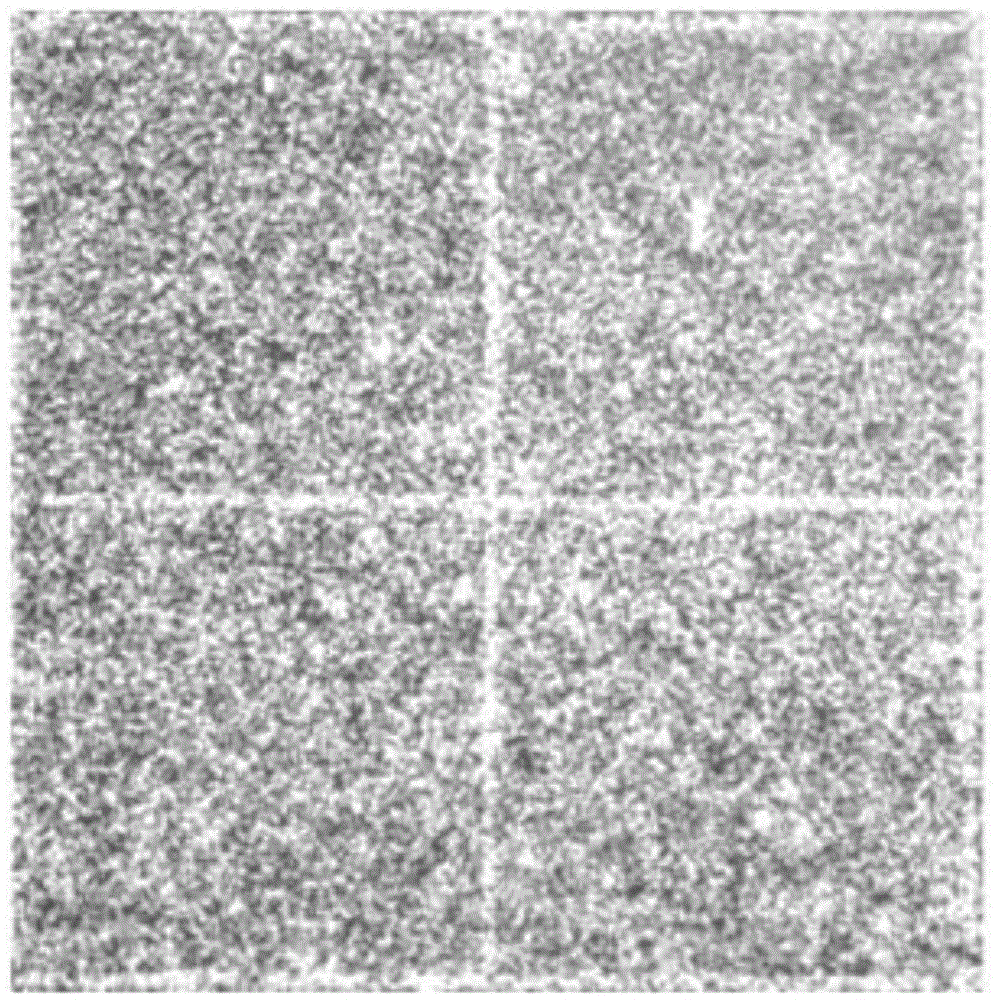

[0046] In this embodiment, the optical material loaded with fluorescent microspheres is exposed under a 40 times optical microscope through a green excitation light for 50 ms, and the optical material loaded with fluorescent microspheres can be seen as bright spots under the optical microscope, which is bonding on the surface of the glass chip. The fluorescence emitted by the fluorescent microspheres under the corresponding wavelength of 530nm excitation proves that the distance between the fluorescent microspheres bonded to the surface of the glass chip is suitable and even.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com