Method of establishing sheet metal high-speed forming limit diagram

A technology of forming limit diagrams and metal sheets, which is applied in the direction of testing metals, analyzing materials, and material inspection products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

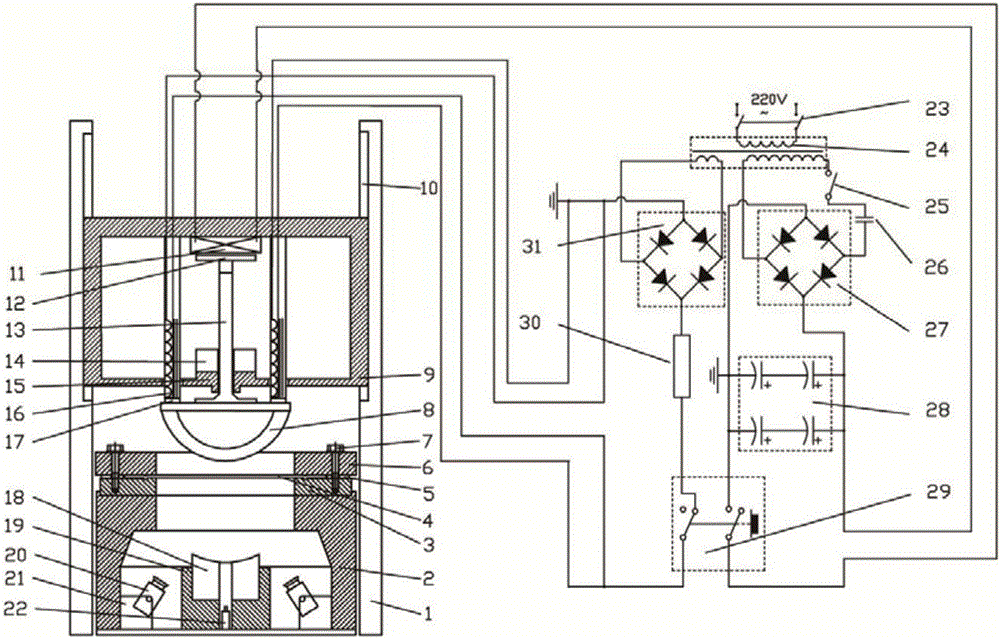

[0030] Attached below Figure 1-11 The present invention is described in detail with embodiment.

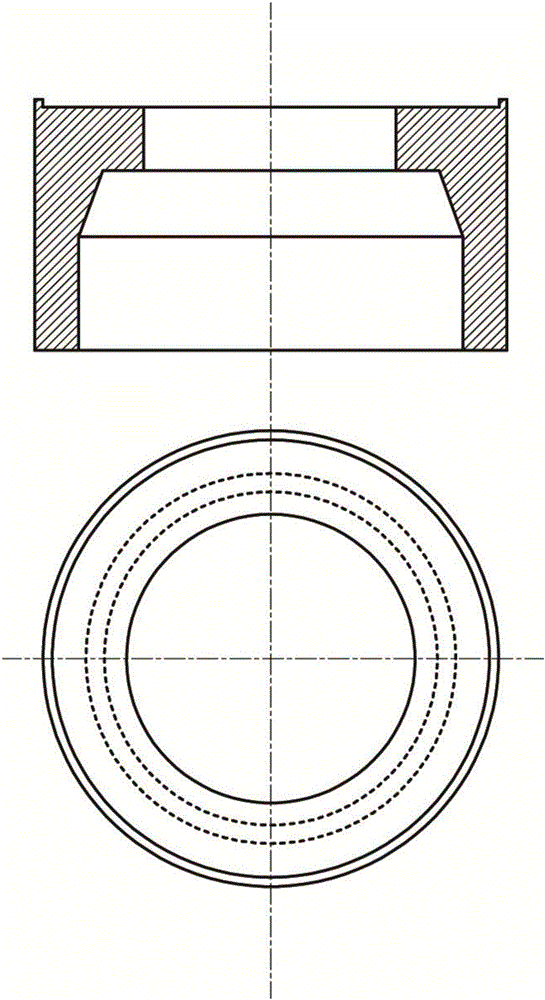

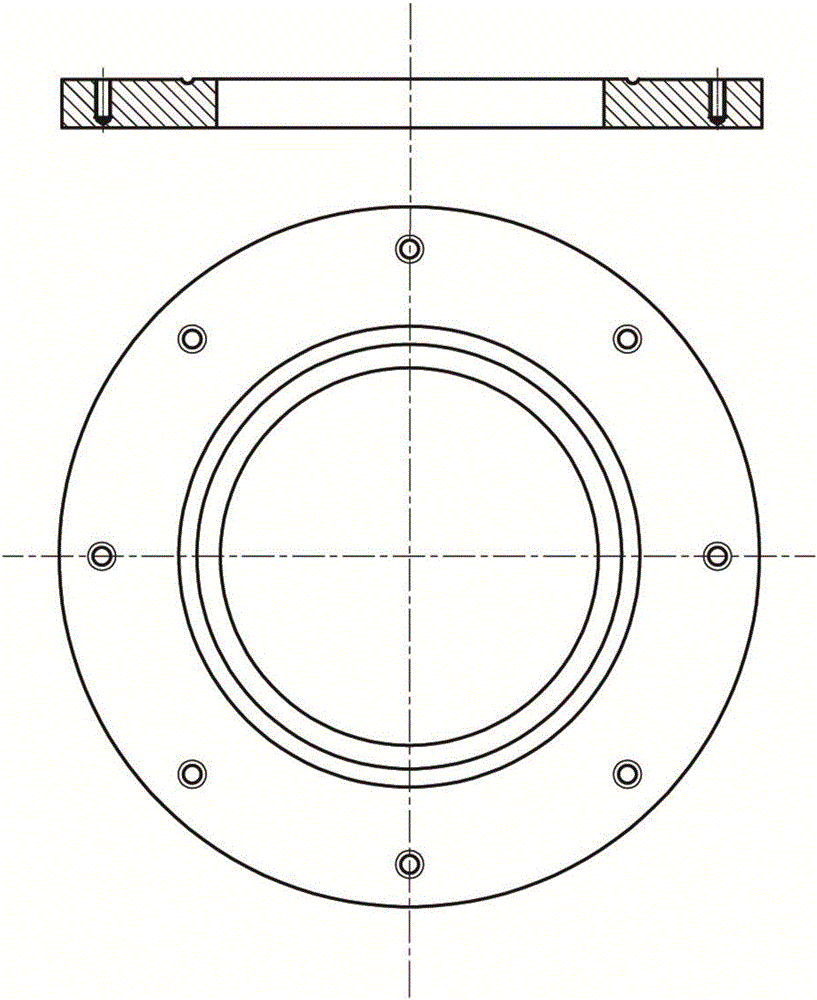

[0031] In order to obtain the limit diagram of high-speed forming of sheet metal, obtain the limit point of high-speed forming of sheet metal, and collect reliable experimental data, the present invention provides an experimental device for high-speed forming of sheet metal. The device includes: guide rail bracket 1, die base 2, Die 3, test sheet 4, washer 5, blank holder 6, fastening screw 7, punch 8, lifting bracket 9, electric guide rail 10, flat coil 11, driving block 12, connecting rod 13, adjustable buffer rubber Pad 14, limit groove 15, electromagnet 16, armature 17, punch rubber buffer block 18, rubber buffer block support 19, high-speed camera 20, high-speed camera support 21, laser range finder 22, main circuit switch 23, Transformer 24, capacitor charging switch 25, protection capacitor 26, high voltage rectifier bridge 27, high voltage capacitor bank 28, punch launch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com