Gas chromatography sample thermal desorption and automatic sample injection device

A technology of gas chromatography and automatic sampling, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the extraction enrichment multiple and selectivity need to be further improved, it is difficult to enrich the target substance, and the quantification is inaccurate, etc., to achieve Fast desorption and sample injection, good reproducibility, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

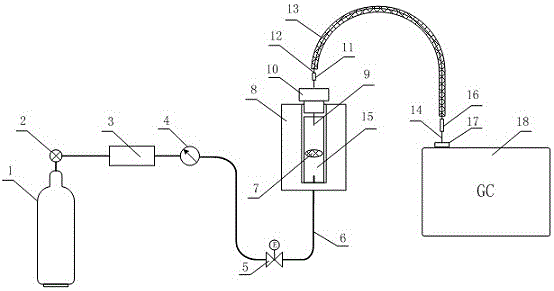

[0014] A gas chromatographic sample thermal desorption and automatic sampling device, which includes a micro high temperature heater 8, a sample tube 15 built into the micro high temperature heater 8, connected to the micro high temperature heater 8, and a nitrogen supply that communicates with the sample tube 15 Gas device, the insulation tube 13 and the two ends of the insulation tube 13 are respectively provided with connected injection needle a9 and injection needle b17, and the injection needle a9 is inserted into the sample tube 15 with the upper port closed. The nitrogen gas supply device is composed of a nitrogen gas cylinder 1, a gas supply pipe 6 connected to the nitrogen gas cylinder 1 at one end, a safety valve 2, a pressure stabilizing valve 3, a pressure gauge 4 and a high-pressure solenoid valve 5 which are sequentially provided on the gas supply pipeline 6 , the other end of the gas supply pipe 6 is inserted into the bottom of the sample tube 15 through the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com