Visual micro-pore structure simulation physical model and manufacturing method thereof

A physical model and microscopic pore technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of high production cost, low success rate, complicated production methods, etc., and achieve the effect of easy observation, high success rate and strong visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

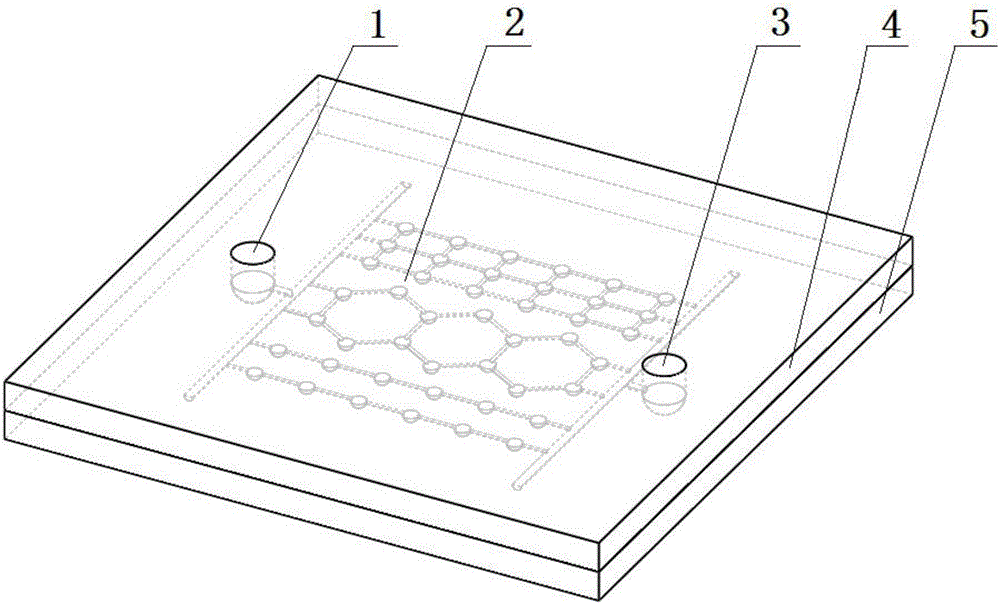

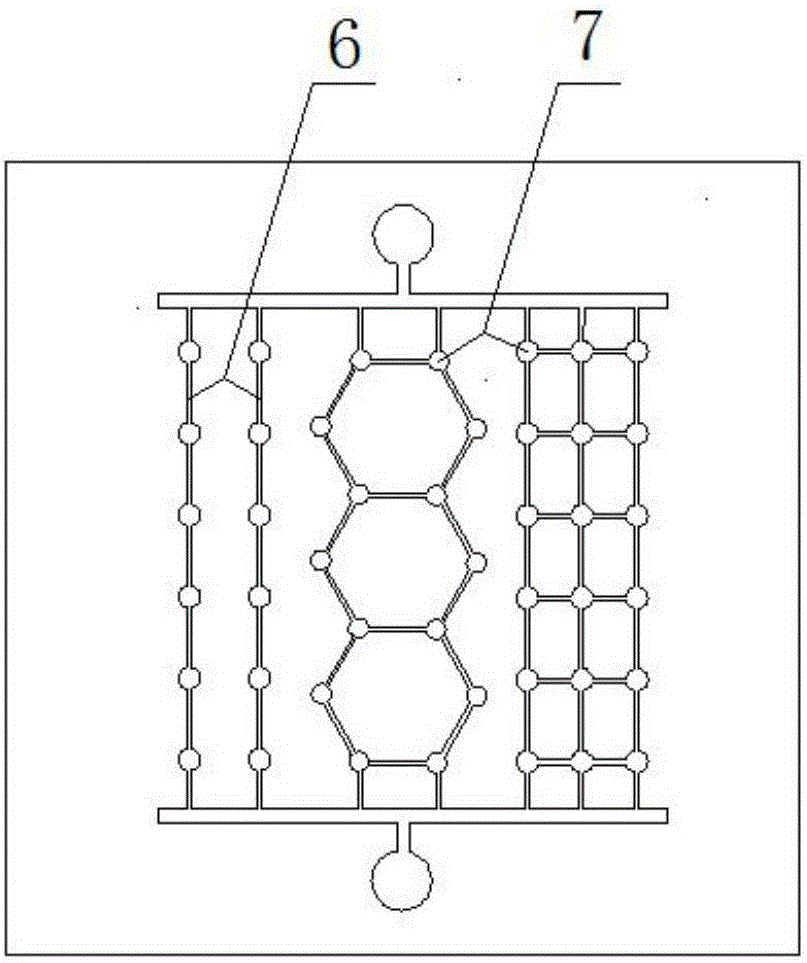

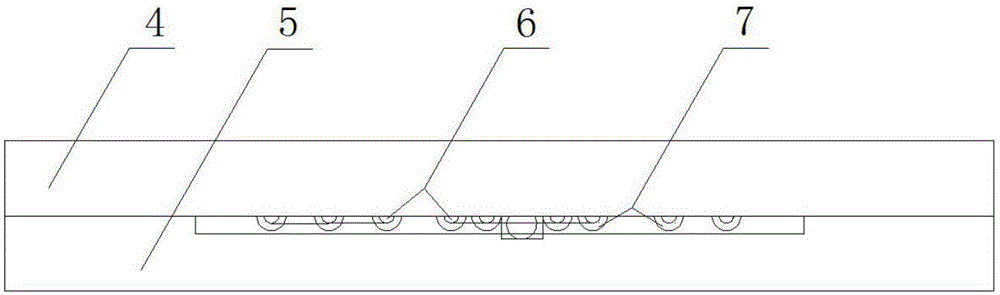

[0045] Such as figure 1 and figure 2 and 3 As shown, a visual microscopic pore structure simulation physical model includes a main board 5 and an attached board 4, wherein the main board 5 is formed by mixing epoxy resin and curing agent, and the attached board 4 is processed by a flat optical glass plate. The attached plate 4 includes an injection port 1 and a production port 3, the main board 5 includes a pore network structure 2, and the pore network structure 2 includes the following three parts:

[0046] The first part of the pore network structure includes two throats 6 extending in parallel from the injection port 1 to the production port 3, and holes 7 are arranged on the two throats;

[0047] The second part of the pore network structure includes two or more hexagonal throats 6 extending end-to-end from the injection port 1 to the production port 3, and holes 7 are arranged on the vertices of the hexagonal throats;

[0048] The third part of the pore network structu...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that a method for making a physical simulation model of a visualized microscopic pore structure includes the following steps:

[0064] (1) Design of pore network structure in the model: According to the casting thin section and mercury intrusion data of actual low and / or ultra-low permeability reservoir rock samples, the reservoir parameters are obtained, including the coordination number (referring to a pore connecting throat number of channels), pore-throat ratio, and throat radius, and draw the pore network structure corresponding to the reservoir parameters; among them, use the software to draw the pores with the same throat radius and pore-throat ratio, but different coordination numbers Network structure; preferably Auto CAD drawing software; in the present embodiment, it is determined that the throat radius is 10-30um, preferably 20um, the pore-throat ratio is 3-6, preferably 4, and the coordination number...

Embodiment 3

[0074] The difference between this embodiment and Embodiment 1 is that a method for making a physical simulation model of a visualized microscopic pore structure includes the following steps:

[0075] Using the simulated physical model obtained by the above preparation to carry out microcosmic oil displacement experiments with different coordination numbers, the experimental equipment is as follows Figure 4 As shown, the visualized microscopic equipment is connected by a video recorder 11 and an image display 12, and the above-mentioned simulated physical model 10 is placed under the video recorder 11, and the injection port of the model is connected to a drive system composed of a displacement pump 8 and an intermediate container 9. For the system, the simulation physical model 10 outlet is connected to the fluid recovery bottle, and the microscopic displacement experiment can be carried out. Use this equipment to observe the fluid displacement status of different coordinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com