Ion acceleration tube

A technology of accelerating tubes and ions, applied in nuclear technology and application fields, can solve the problems of lack of simple structure and low beam intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

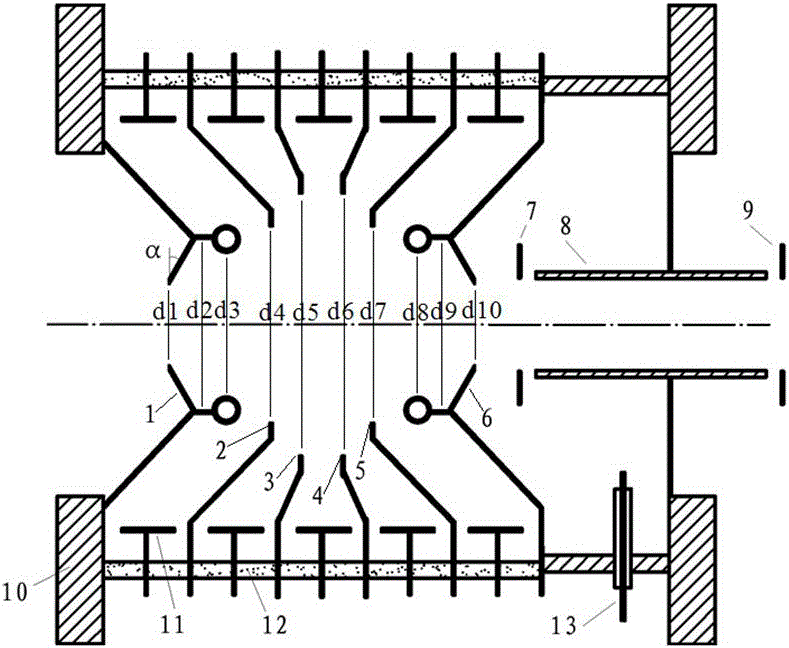

[0030] The ion beam to be accelerated is a deuterium ion beam, the beam intensity is 1mA, the voltage at both ends of each accelerating tube module is 250kV, the length is 200mm, the average acceleration gradient is 1.25MV / m, the ceramic insulating ring is 13, and the external working environment is 0.6MPa High pressure SF 6 For gas, the apertures of the entrance focusing accelerating electrode I1 and the exit defocusing accelerating electrode II6 are 30 mm, the apertures of the entrance accelerating focusing electrode II2 and the exit defocusing accelerating electrode I5 are 50 mm, the apertures of the intermediate accelerating electrode I3 and the intermediate accelerating electrode II4 are 70 mm, The length of the drift tube 8 is 80 mm, and the potential of the stop electrode 7 and the stop electrode 9 is the same, which is 2 kV lower than that of the drift tube 8 . 20 identical ion accelerating tube modules are assembled together to form an ultra-high-voltage strong-curren...

Embodiment 2

[0032]The ion beam to be accelerated is a proton beam, the beam intensity is 2mA, the voltage across each accelerating tube is 225kV, the length is 200mm, the average acceleration gradient is 1.125MV / m, the ceramic insulating ring is 13, and the external working environment is a high-voltage SF of 0.6MPa 6 For gas, the apertures of the entrance focusing accelerating electrode I1 and the exit defocusing accelerating electrode II6 are 30 mm, the apertures of the entrance accelerating focusing electrode II2 and the exit defocusing accelerating electrode I5 are 50 mm, the apertures of the intermediate accelerating electrode I3 and the intermediate accelerating electrode II4 are 70 mm, The length of the drift tube 8 is 80 mm, and the potential of the stop electrode 7 and the stop electrode 9 is the same, which is 2 kV lower than that of the drift tube 8 . 36 sections of the same accelerating tubes are assembled together to form a proton beam with a length of 7.2 meters, a total acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com