White spirit vinasse classified rice hull removing method and organic liquid fertilizer base solution preparation method

A technology of white distiller's grains and rice husks, which is applied in the directions of organic fertilizers, fertilization devices, and solid waste removal, etc., can solve the problems of high content of rice husks that are difficult to degrade, high processing costs, and long degradation time, and can solve the problems of high content of rice husks. , moderate pH, to achieve the effect of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

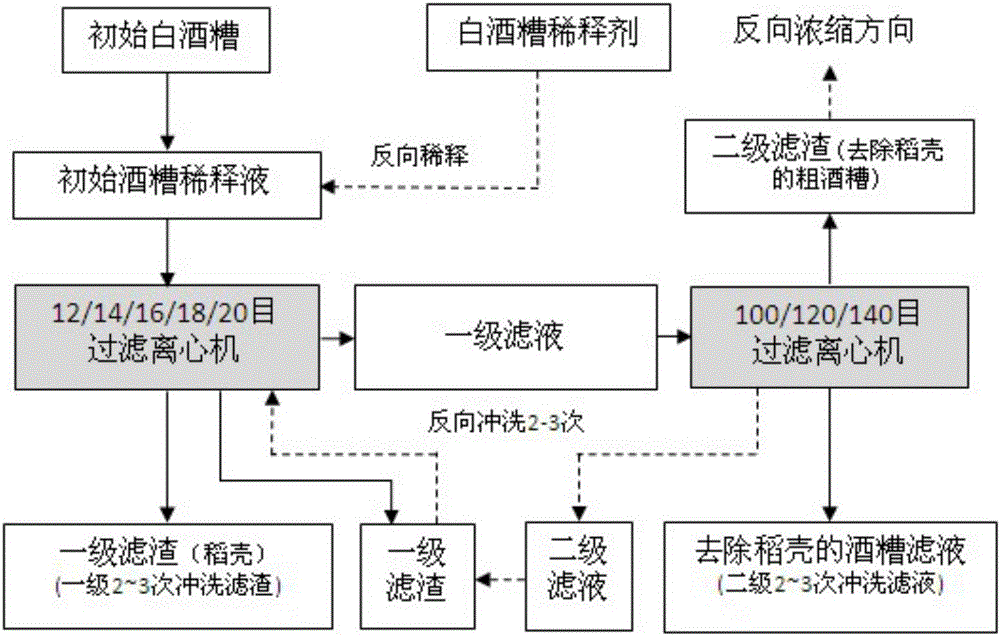

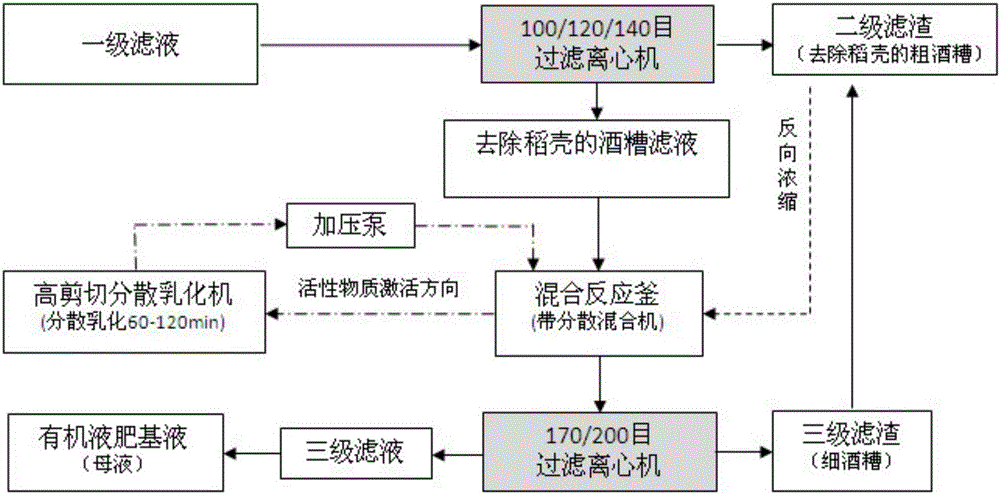

[0053] This embodiment is used to illustrate a kind of distiller's grains graded treatment and removes the rice husk isolate (the coarse distiller's grain of removing rice husk and the distiller's grain filtrate of removing rice husk) as raw material and prepares the method for organic liquid fertilizer base liquid, comprises the following steps:

[0054] (1) Remove rice husk: input water as the distiller's grains diluent into a buffer tank with stirring, start the agitator, and add the initial distiller's grains in batches (wherein, the rice husk content accounts for 50% of the total solid content, containing 60% water), stirred and mixed, diluted to 10% solid content of the initial distiller's grains dilution, pumped into LX-950-12 mesh filter centrifuge for primary filtration and separation. Among them, the "primary filter residue" (rice husk) enters the primary rice husk storage tank, and the primary filtrate enters the primary filtrate storage tank to be processed. The "p...

Embodiment 2

[0057] This embodiment is used to illustrate a kind of distiller's grains graded treatment and removes the rice husk isolate (the coarse distiller's grain of removing rice husk and the distiller's grain filtrate of removing rice husk) as raw material and prepares the method for organic liquid fertilizer base liquid, comprises the following steps:

[0058] (1) Remove rice husk: input ammoniacal liquor (ammonia content 18%) into the buffer tank with stirring as the initial distiller's grains diluent, start the agitator, add initial distiller's grains in batches (wherein the content of rice husk accounts for the solid 48% of the total amount, water content 55%), stirred and mixed, diluted to 20% solid content of the initial distiller's grain dilution, pumped into LX-950-16 mesh filter centrifuge for primary filtration and separation. Among them, the "primary filter residue" (rice husk) enters the primary rice husk storage tank, and the primary filtrate enters the primary filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com