Coke storage and conveying equipment with reversing device

A technology of reversing device and conveying equipment, applied in conveyer objects, transportation and packaging, chute and other directions, can solve the problems of coke adhesion, serious environmental pollution, affecting the conveying efficiency of elevators, etc., to prevent accumulation and improve the environment. , The effect of reducing the scattering problem of sprinkling and coke powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better illustrate the present invention, specific examples are used to illustrate, but the specific examples do not limit the scope of protection of the present invention.

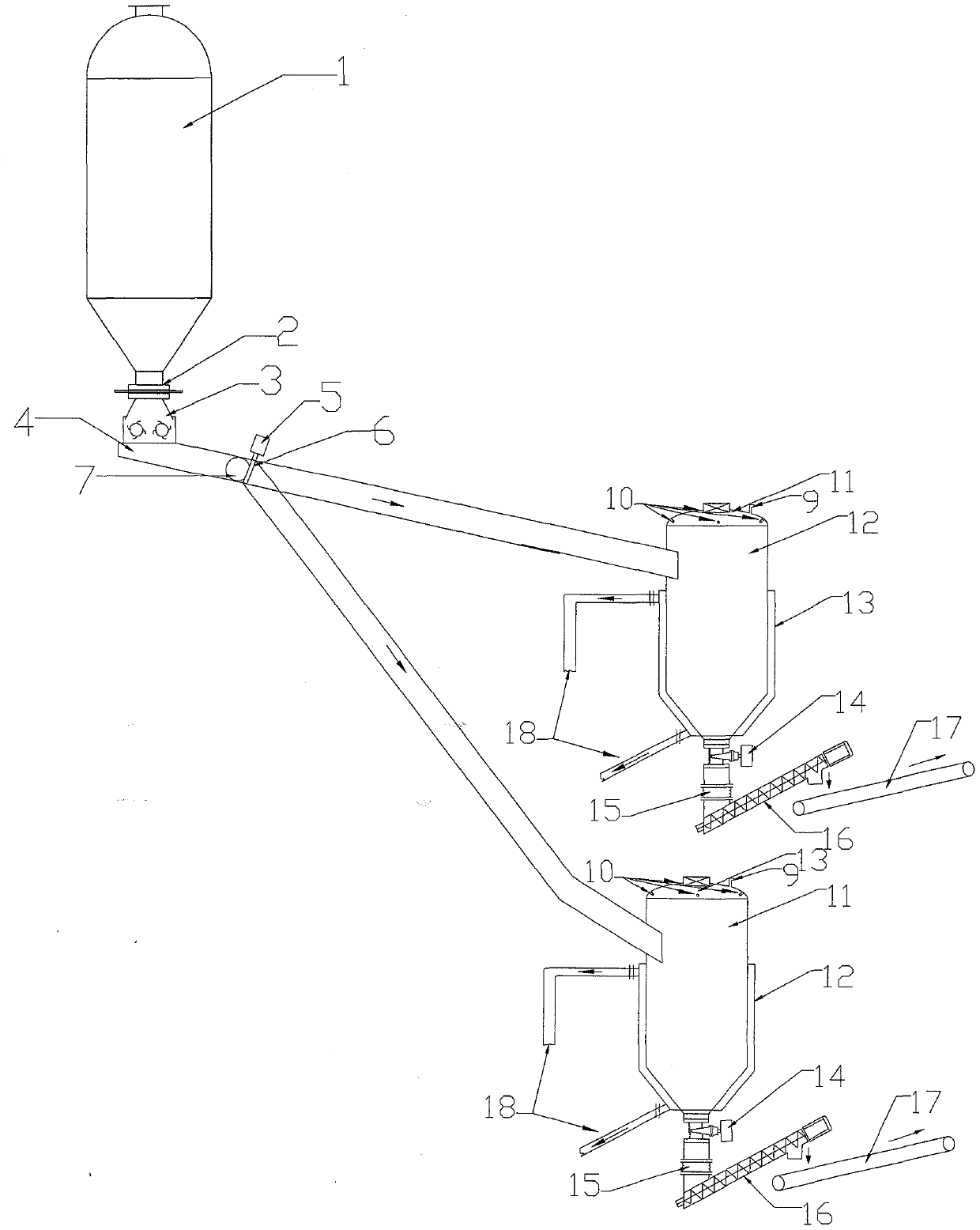

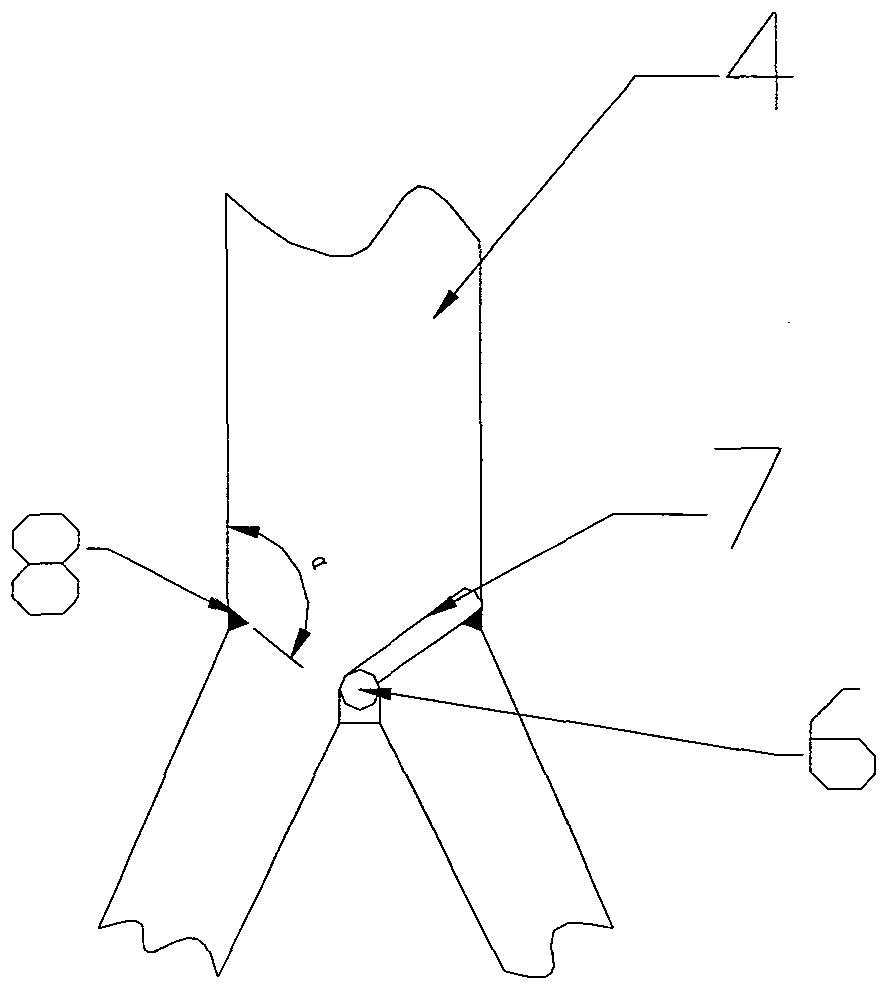

[0025] as attached figure 1 As shown, a coke storage and conveying device with a reversing device in the present invention includes a coke tower 1, a bottom cover machine 2, a crusher 3, a three-way inclined chute 4, a chute baffle drive device 5, a rotating shaft 6, and a chute stop Plate 7, sealing ring 8, vent hole 9, spray device 10, coke storage tank inner cylinder 11, coke storage tank outer cylinder 12, coke storage tank top 13, flat gate valve 14, hose 15, lifting equipment 16, belt conveyor 17, drainage pipe 18. After the petroleum coke is output from the coke tower, it enters the crusher through the bottom cover machine. After the crusher crushes the petroleum coke, it is output to two coke storage tanks through the three-way inclined chute, and the petroleum coke is collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com