Segmented drying method for starch system water-absorbent resin

A water-absorbent resin and segmented drying technology is applied in the field of preparation of starch-based water-absorbent resins, which can solve problems such as affecting the water-absorbent properties of water-absorbent resins, and achieve the effects of facilitating continuous industrial production, not affecting water-absorbent properties, and taking less time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

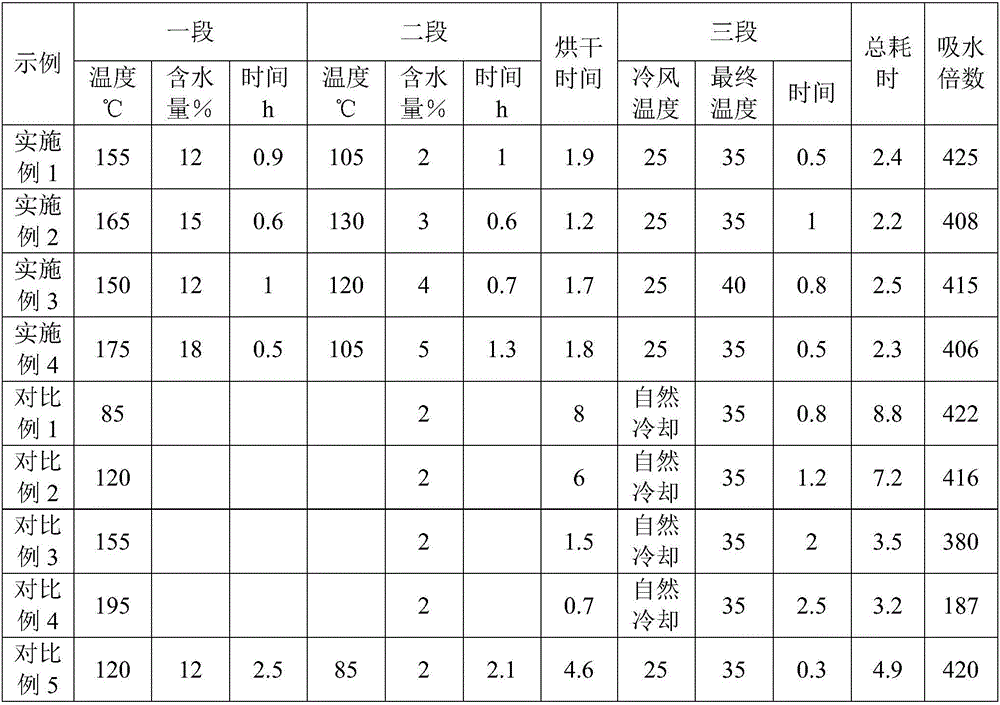

[0020] The following non-limiting examples illustrate the invention. Examples and comparative examples are carried out under the same oven and the same sample size.

[0021] A method for drying starch-based water-absorbent resins, including cut and minced gel blocks, which are formed by reacting raw materials such as acrylic acid, starch, and alkali, and then polymerized by irradiation. For example, the preparation method is as follows:

[0022] 1. Formula (parts by weight):

[0023] 45-65 parts of acrylic acid, 10-40 parts of potassium hydroxide, 5-30 parts of diammonium hydrogen phosphate, 0.05-5 parts of glycerol, and 1-10 parts of pregelatinized starch.

[0024] 2. Steps:

[0025] (1) Neutralization reaction: add water to pre-gelatinized starch and stir for 15-30 minutes to make gelatinized liquid, slowly add potassium hydroxide and diammonium hydrogen phosphate to dissolve, then slowly add acrylic acid for neutralization, finally add glycerin and mix well ;

[0026] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com