Preparation method of acrylate polymer particles for PA6/PBT blend modification

A technology of acrylate and polymer, which is applied in the field of blending modification of engineering plastic base resins, can solve the problems of low impact strength and poor compatibility of blends, and achieve the effect of improving notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

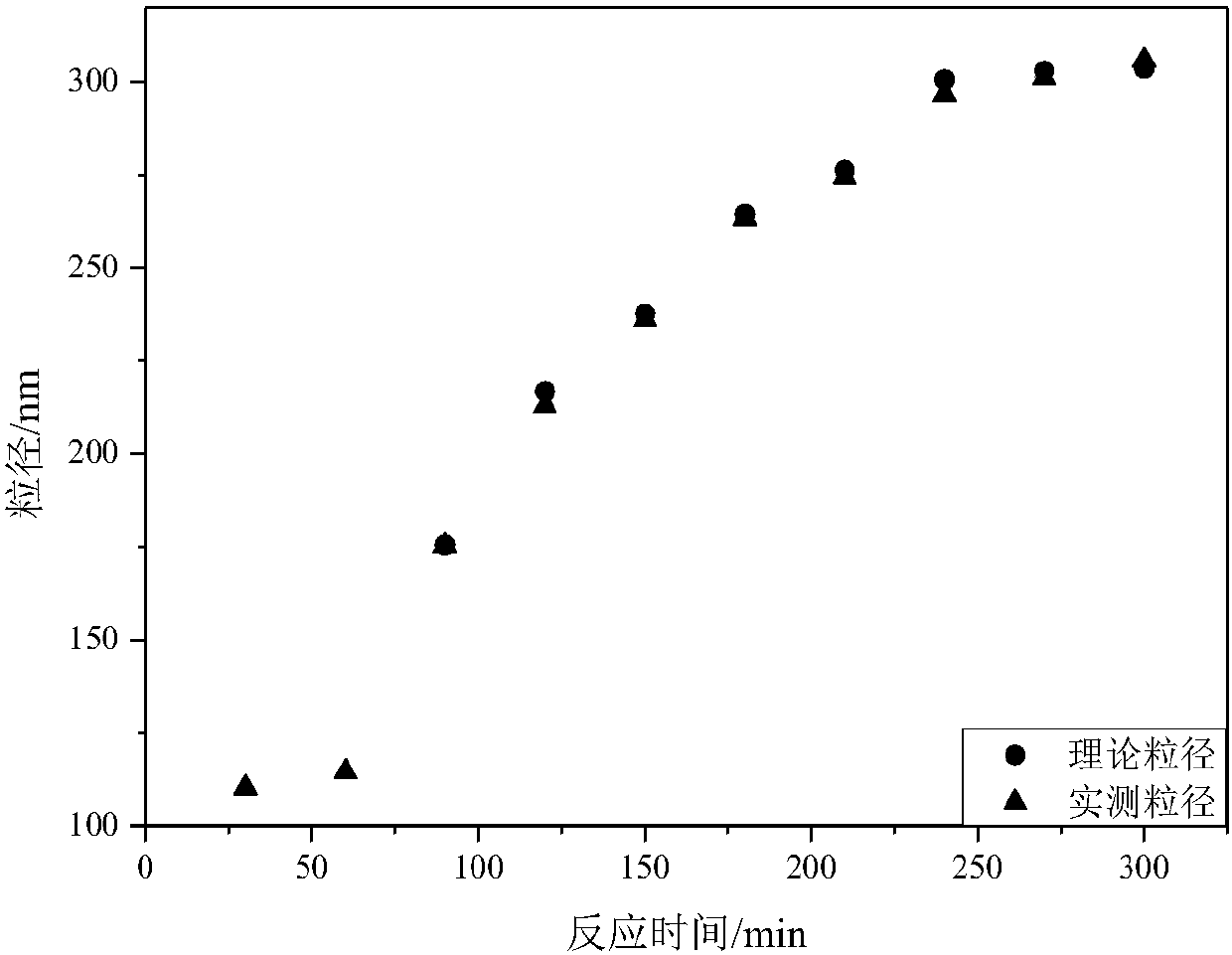

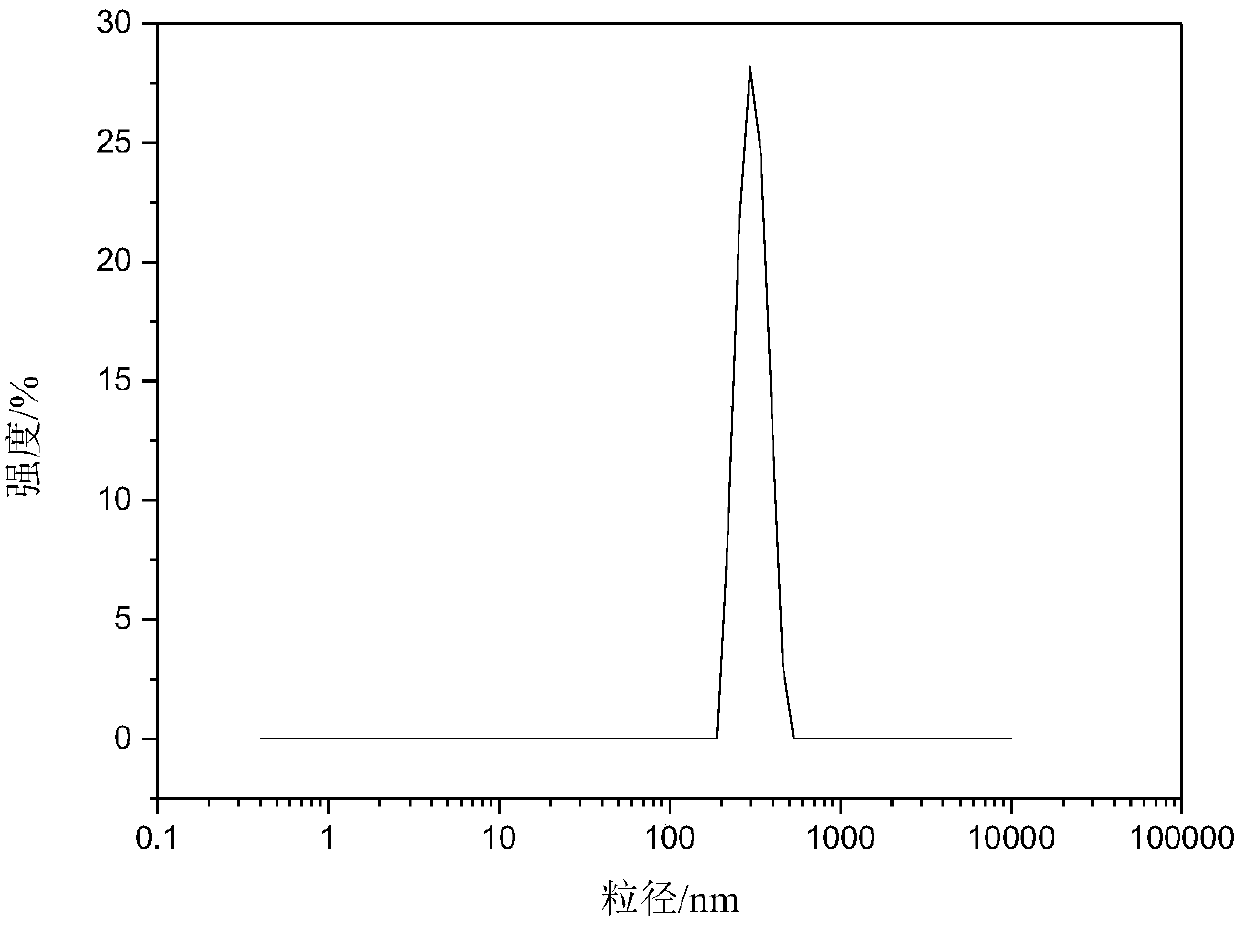

Method used

Image

Examples

Embodiment 1

[0044] a. Preparation of seed monomer pre-emulsion

[0045] Firstly, nitrogen was evacuated into a 500ml four-neck flask for 30min, and 0.51g of anionic emulsifier dioctyl succinate sodium sulfonate and 140g of deionized water were added and stirred for 30min; then, 10g of n-hexyl acrylate was added to the reaction flask and 0.054g cross-linking agent allyl acrylate, and mixed and stirred for 10min to obtain the seed monomer pre-emulsion for subsequent use;

[0046] b. Preparation of core layer monomer pre-emulsion

[0047] Add 1.85g of anionic emulsifier dioctyl succinate sodium sulfonate, 150g of n-hexyl acrylate monomer and 0.75g of crosslinking agent allyl acrylate into a 250ml beaker, stir for 20min under the action of electromagnetic stirring to make it fully mixed, Promptly obtain the nuclear layer monomer pre-emulsion, for subsequent use;

[0048] c. Preparation of shell monomer pre-emulsion

[0049] Add 0.80g of anionic emulsifier dioctyl succinate sodium sulfonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com