P4VP-b-PMA (Az) block copolymer, high-through hexagonal prism membrane with adjustable prism diameter and preparation method of membrane

A technology of block copolymer and p4vp-b-pma, applied in the field of new polymer materials, can solve the problems of limited application, weak complexing force of transition metal ions, etc., and achieve the effect of strong metal complexing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

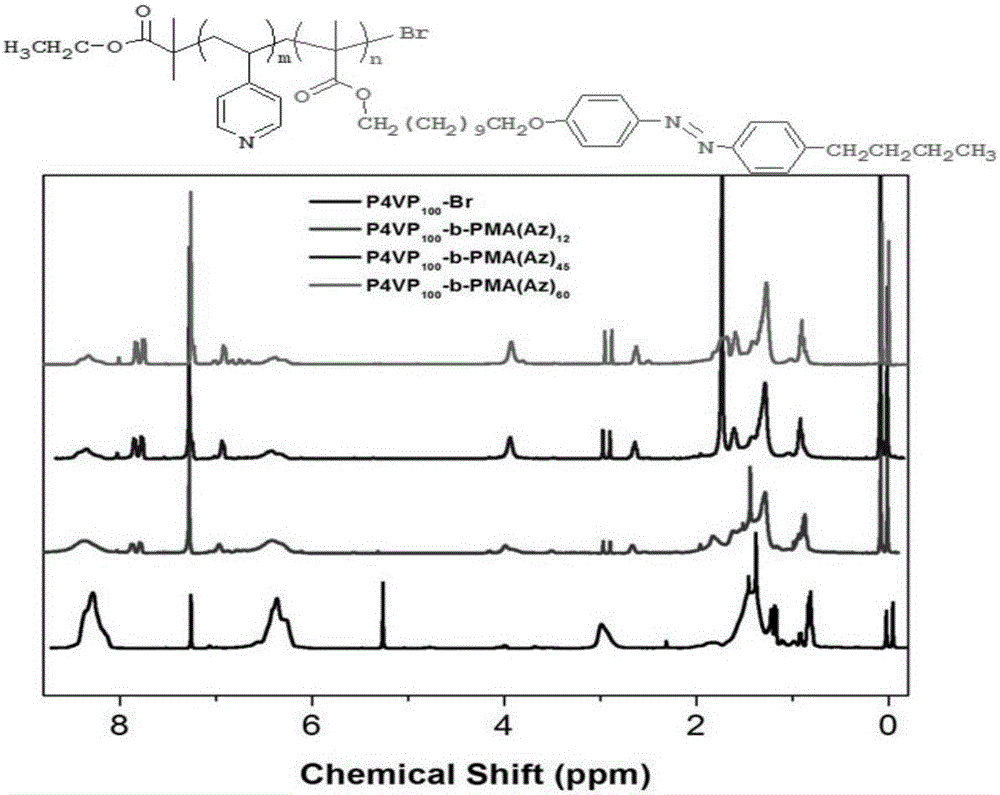

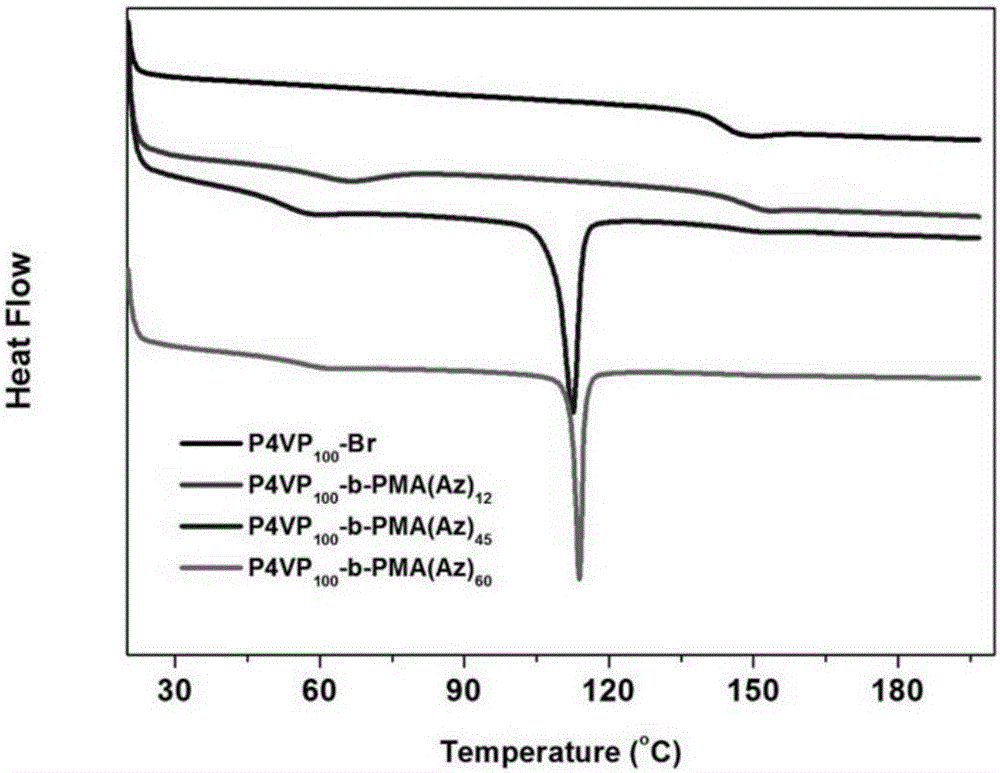

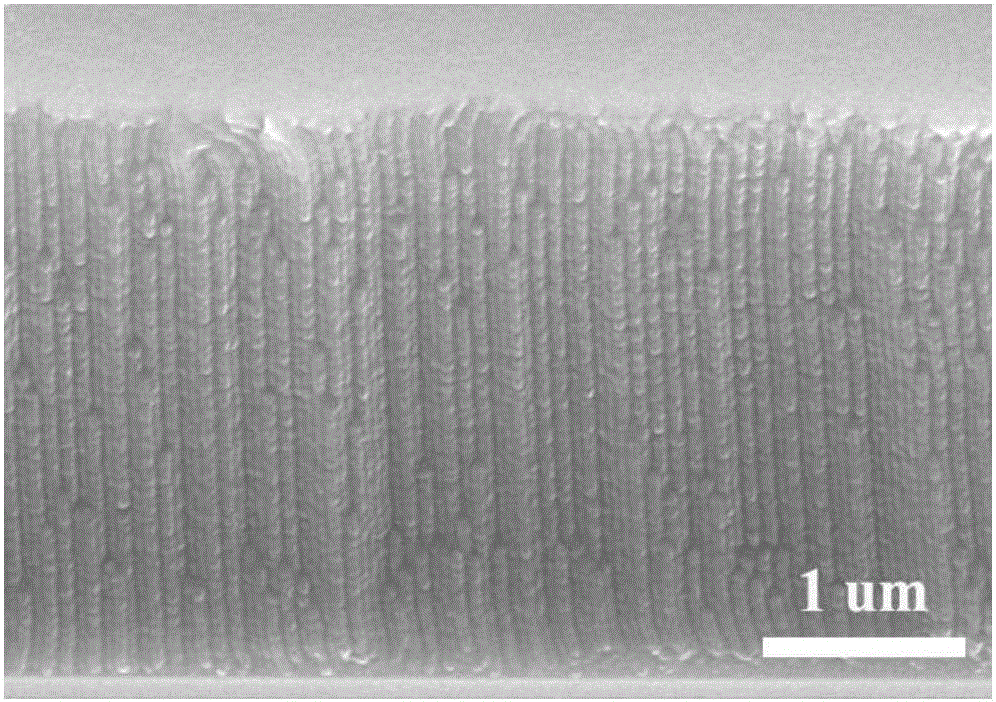

[0056] P4VP 100 -b-PMA(Az) 60 The preparation method of block copolymer, comprises the steps:

[0057] 1) Synthesis of P4VP macroinitiator:

[0058] Into a clean Shrek bottle, add 10ml of isopropanol after dehydration, 100 times the molar equivalent of ethyl α-bromoisobutyrate, that is, 11ml, 150.4ul of ethyl α-bromoisobutyrate, 545.6 The ligand tris(2-dimethylaminoethyl)amine (Me 6 TREN), mix well. Then, the Shrek bottle was frozen in liquid nitrogen, 100 mg of cuprous chloride (CuCl) was added, and the top of the bottle was sealed with a rubber stopper. Wherein the feeding molar ratio is, initiator:ligand:CuCl=1:2:1. Then evacuate for 5 minutes under freezing, thaw and stir for 5 minutes under nitrogen, and cycle 3 times. Finally, tighten the high-vacuum shut-off valve of the Shrek bottle under the condition of freezing and evacuating, then thaw it and put it in an oil bath at 45°C to stir and react for 16 hours.

[0059] When the reaction time is up and the viscosity...

Embodiment 2

[0064] P4VP 16 -b-PMA(Az) 5 The preparation method of block copolymer, with embodiment 1, its difference only lies in:

[0065] In step 1), 1-chlorophenylethane (PE-Cl) is used as the initiator, and initiator:ligand:CuCl=1:2.5:1 (molar ratio). The dosages of each substance are: initiator 0.25g, ligand 1ml, CuCl 173.2mg, 4VP 2.5g, reaction solvent DMF 6mL. Finally, a P4VP with a block number of 16 is obtained 16 -Br macroinitiator 2.5g;

[0066] In step 2), with pentamethyldiethylenetriamine (PMDETA) as ligand, and macromolecular initiator: ligand: CuCl=1:3:1 (molar ratio), the consumption of each material is respectively: initiator 0.2g, ligand 0.062g, CuCl 0.011g; reaction solvent DMF 4mL, chlorobenzene 4ml.

Embodiment 3

[0068] P4VP 100 -b-PMA(Az) 12 The preparation method of block copolymer, with embodiment 1, its difference only lies in:

[0069] In step 1), methyl α-bromoisobutyrate is used as the initiator, and initiator:ligand:CuCl=1:3:1 (molar ratio). The dosage of each raw material is: initiator 0.3g, ligand 1.15g, CuCl 161mg, 4VP 18g, solvent DMF 3ml, isopropanol 5ml. Obtaining the P4VP-Br macromolecular initiator 10g that block number is 100 at last;

[0070] In step 2), with pentamethyldipropylenetriamine as ligand, and macromolecular initiator: ligand: CuCl=1:2:1 (molar ratio), the consumption of each raw material is respectively: initiator 0.5g, Ligand 0.019g, CuCl 5mg; solvent chlorobenzene 8ml, monomer MA(Az) 0.3g, that is, the amount of 12 molar equivalents of P4VP-Br.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com