Bubbling fluidized bed device used for desorptive regeneration of powdery sulfur-bearing active coke

A bubbling fluidized bed and activated coke technology, which is applied in the field of air pollutant control and desulfurization waste resource utilization, can solve the problems of limited mass transfer and heat transfer efficiency of sulfur-loaded activated coke/carbon, and achieve complete desorption and efficient regeneration. , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A bubbling fluidized bed device for desorption and regeneration of powdery sulfur-laden activated coke, comprising a desorption tower 1, the desorption tower 1 is sequentially composed of a reheater 9 in the tower, a bubbling fluidization section, and a cooling section from top to bottom, The bubbling fluidization section includes an air distribution plate 11 at the bottom and a feeding pipe 10 fixed on the air distribution plate 11, and the cooling section is a tube-and-tube heat exchanger, which includes an external heat exchanger. The heat medium tube box 13 and the internal heat exchange tubes, the bubbling fluidized bed device is placed vertically, and the bottom is the outlet of the desorbed regenerated active coke.

Embodiment 2

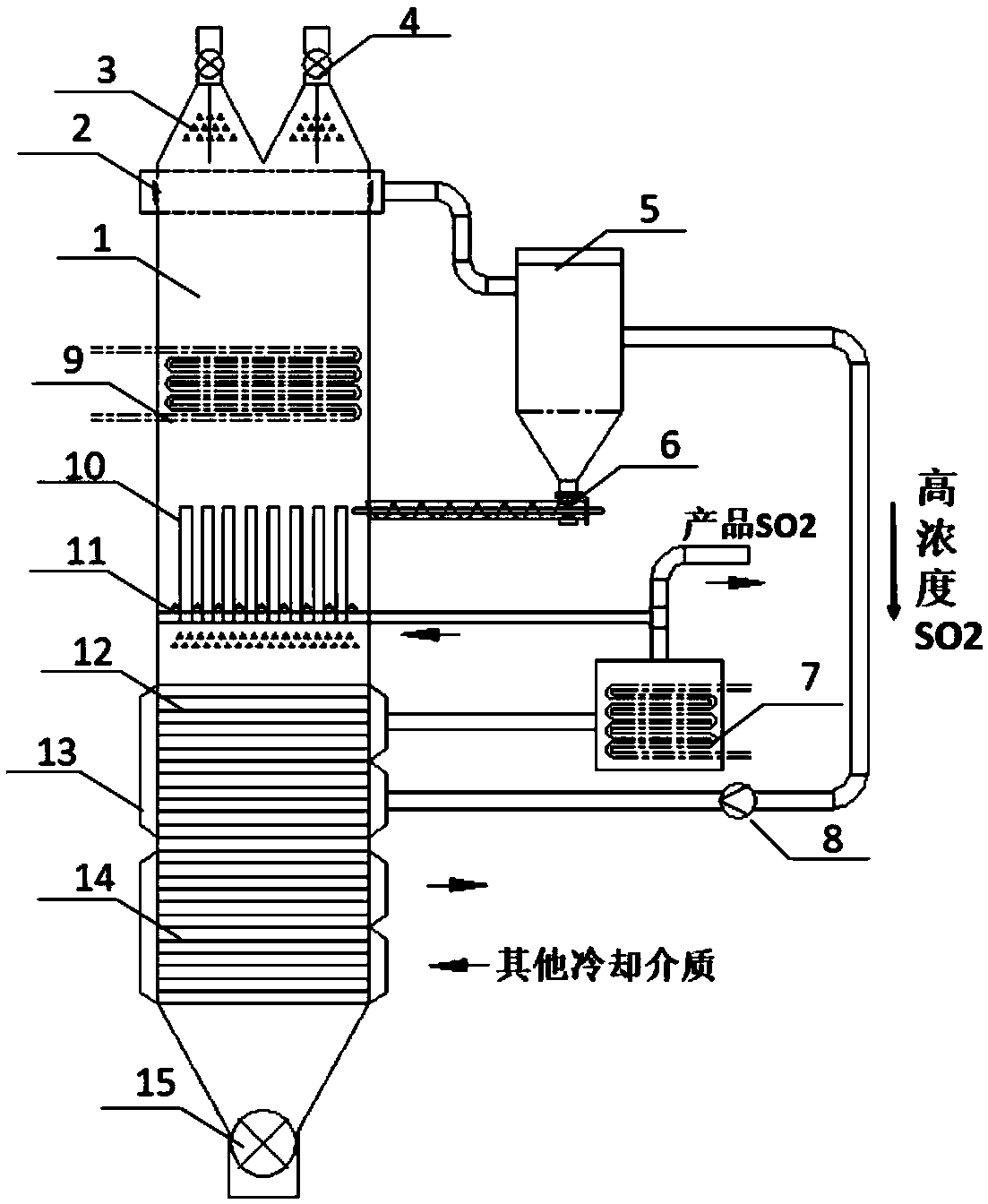

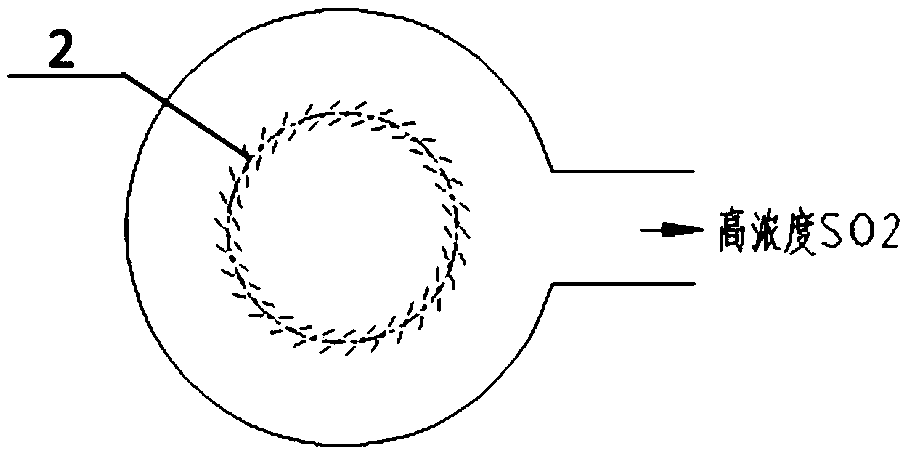

[0049] Such as figure 1 Shown is the first arrangement of a bubbling fluidized bed device used for desorption and regeneration of powdered sulfur-laden activated coke.

[0050] A bubbling fluidized bed device for desorption and regeneration of powdery sulfur-laden activated coke, comprising a desorption tower 1, the desorption tower 1 is sequentially composed of a reheater 9 in the tower, a bubbling fluidization section, and a cooling section from top to bottom, The bubbling fluidization section includes an air distribution plate 11 at the bottom and a feeding pipe 10 fixed on the air distribution plate 11, and the cooling section is a tube-and-tube heat exchanger, which includes an external heat exchanger. The heat medium tube box 13 and the internal heat exchange tubes, the bubbling fluidized bed device is placed vertically, and the bottom is the outlet of the desorbed regenerated active coke.

[0051] The top of the desorption tower is followed by a louver exhaust device 2...

Embodiment 3

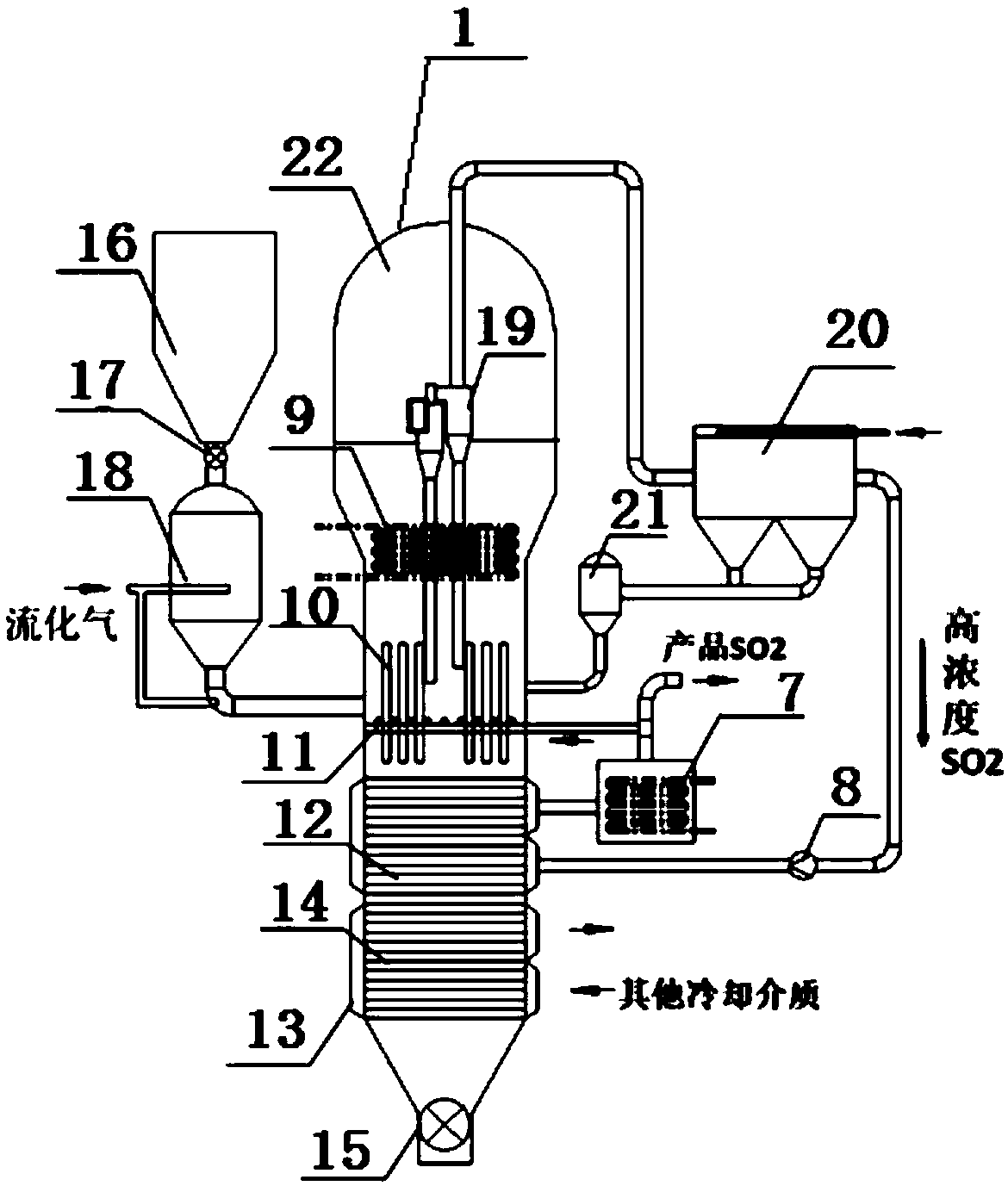

[0058] Such as image 3 Shown is a second arrangement of a bubbling fluidized bed device for desorption regeneration of powdered sulfur-laden activated coke.

[0059] A bubbling fluidized bed device for desorption and regeneration of powdery sulfur-laden activated coke, comprising a desorption tower 1, the desorption tower 1 is sequentially composed of a reheater 9 in the tower, a bubbling fluidization section, and a cooling section from top to bottom, The bubbling fluidization section includes an air distribution plate 11 at the bottom and a feeding pipe 22 fixed on the air distribution plate 11, and the cooling section is a tube-and-tube heat exchanger, which includes an external heat exchanger. The heat medium tube box 13 and the internal heat exchange tubes, the bubbling fluidized bed device is placed vertically, and the bottom is the outlet of the desorbed regenerated active coke.

[0060] The lower end of the feeding pipe 22 passes through the air distribution plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com