Water-based adhesive and preparation method thereof

A water-based adhesive, water-based technology, applied in the direction of adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problems of slow curing speed and insufficient initial adhesion, and achieve fast curing and initial The effect of strong adhesion and low film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

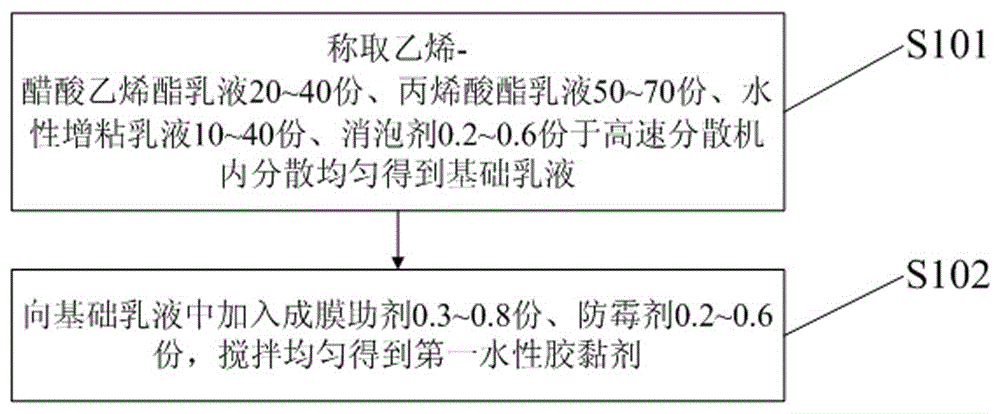

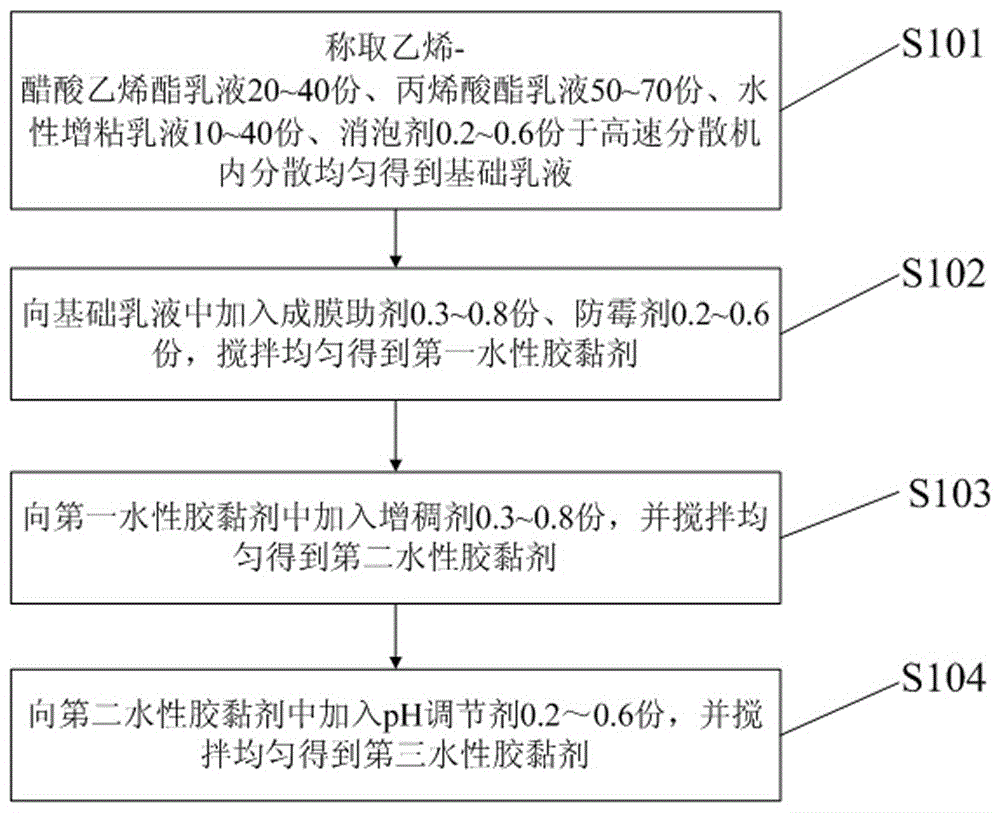

[0043] On the basis of the water-based adhesive provided in the above embodiments of the present invention, the present invention further provides a method for preparing the water-based adhesive, please refer to figure 1 , The preparation method of the water-based adhesive of this embodiment includes the following steps:

[0044] S101: Weigh 20-40 parts of ethylene-vinyl acetate emulsion, 50-70 parts of acrylate emulsion, 10-40 parts of water-based tackifying emulsion, and 0.2-0.6 parts of defoamer, and disperse uniformly in a high-speed dispersing machine to obtain a basic emulsion.

[0045] Among them, when dispersing, the speed of the high-speed disperser is 200-300r / min, and the stirring time is 20-40min.

[0046] Among them, in the embodiment of the present invention, the acrylate emulsion can be composed of one or two of vinegar-acrylic emulsion and pure acrylic emulsion.

[0047] Among them, the vinegar-acrylic emulsion used in the embodiment of the present invention has a solid...

Embodiment 1

[0065] (1) Accurately weigh 10 parts each of DA102H and EAF68, 60 parts of pure acrylic emulsion, 18 parts of water-based acrylic modified rosin thickening emulsion, and 0.3 parts of silicone defoamer in a high-speed disperser, 300r / min, stirring for 30min, Get a base emulsion;

[0066] (2) Add 0.5 part of propylene glycol phenyl ether and 0.3 part of antifungal agent to the basic emulsion prepared in (1), 600r / min, and stir for 30min to obtain an environmentally friendly water-based adhesive;

[0067] (3) Add 0.5 part of the thickener thickener to the environmentally friendly water-based adhesive prepared in (2) to obtain an environmentally friendly water-based adhesive with suitable viscosity;

[0068] (4) Add 0.4 part of pH regulator to the environmentally friendly water-based adhesive prepared in (3) to obtain an environmentally-friendly water-based adhesive with excellent performance;

[0069] (5) Apply the prepared environmentally friendly water-based adhesive to the fully autom...

Embodiment 2

[0075] (1) Accurately weigh 10 parts each of DA102H and EAF68, 60 parts of vinegar-acrylic emulsion, 18 parts of water-based acrylic modified rosin viscosity increasing emulsion, and 0.3 parts of silicone defoamer in a high-speed disperser, 300r / min, stirring for 30min, Get a base emulsion;

[0076] (2) Add 0.5 part of propylene glycol phenyl ether and 0.3 part of antifungal agent to the basic emulsion prepared in (1), 600r / min, and stir for 30min to obtain an environmentally friendly water-based adhesive;

[0077] (3) Add 0.5 part of the thickener thickener to the environmentally friendly water-based adhesive prepared in (2) to obtain a water-based environmentally friendly water-based adhesive with suitable viscosity;

[0078] (4) Add 0.4 parts of pH regulator to the environmentally friendly water-based adhesive prepared in (3) to obtain an environmentally-friendly water-based adhesive with excellent performance;

[0079] (5) Apply the prepared environmentally friendly water-based ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com