Power station boiler tail flue rectangular section flue gas measuring device

A technology with a rectangular section and a tail flue, which is applied in the measurement device, sampling device, sampling and other directions, can solve the problems of affecting the measurement accuracy, inconvenient operation, and high labor intensity of the measurement personnel, and achieve the effect of improving the measurement accuracy and reducing the work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

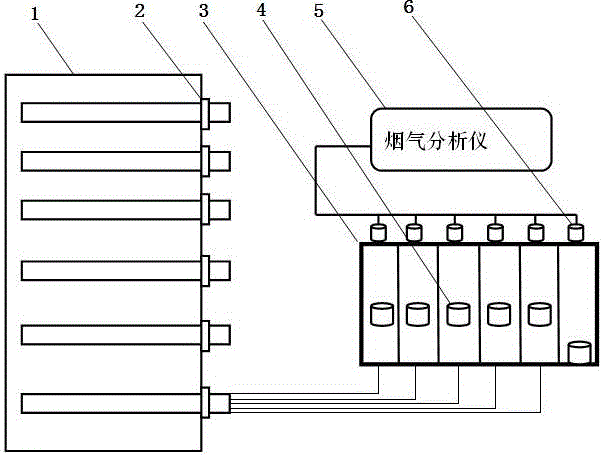

[0012] The specific embodiment of the present invention is as figure 1 shown.

[0013] This embodiment is realized in this way. This embodiment is a flue gas measuring device with a rectangular cross-section at the tail flue of a utility boiler, which includes a multi-tube multifunctional sampling gun 2 , a float flow meter 3 , and a flue gas analyzer 5 .

[0014] Each multi-tube multifunctional sampling gun of this embodiment is a sampling gun that meets the measurement requirements of the national standard GB10184-88 grid method according to the size of the rectangular section of the tail flue 1 on site. The number of steel pipes to be measured and the length to be measured should be It meets the requirements of the site, and at the same time, the central part of the sampling gun is equipped with thermocouples with the same number and length as the sampling steel pipe, and meets the requirements of flue gas sampling and temperature measurement. The rotameter is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com