Rock fracturing simulation test specimen with crack, preparation method for rock fracturing simulation test specimen, simulation test apparatus and simulation test method

A technology for simulating samples and simulating tests, which is applied in the preparation of test samples, the application of stable tension/pressure to test the strength of materials, measuring devices, etc., which can solve the problems of fracture interference and fracturing expansion models, and the inability to study the main pressure Communication characteristics of fractures and weak bedding planes in shale, difficulty in realizing complex fracture network structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

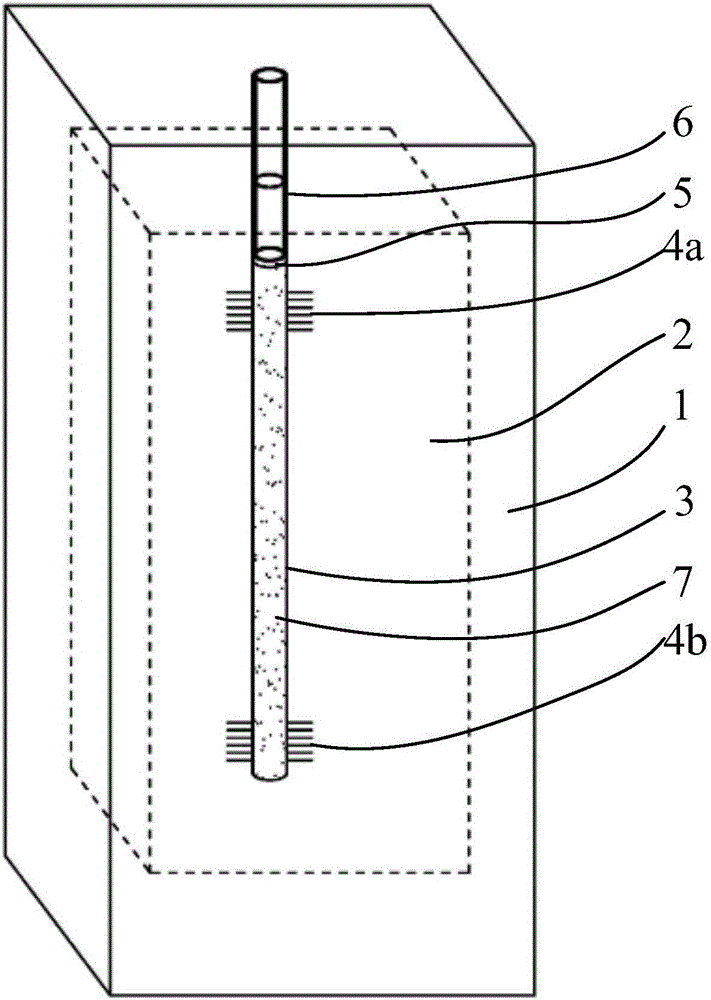

[0063] See attached figure 1 The simulated rock fracturing sample with cracks provided in Embodiment 1 of the present invention includes a rock sample body 2 , a fracturing fluid injection pipe 6 , and a pouring material 1 . The pouring material 1 is coated on the outside of the body 2, so that the formed rock fracturing simulation sample with cracks is a rectangular parallelepiped as a whole, and a blind hole 3 is set starting from one end face of the rectangular parallelepiped, and the blind hole 3 ends at the body 2 , the fracturing fluid injection pipe 6 is fixedly connected to the wall of the blind hole 3, and an accommodating space is reserved between the bottom end of the fracturing fluid injection pipe 6 and the bottom end of the blind hole 3, starting from the wall of the blind hole 3 , extending toward the body 2 with a plurality of perforations 4a-4b.

[0064] Wherein, the rock fracturing simulation sample with cracks also includes a binder, and the outer diameter ...

Embodiment 2

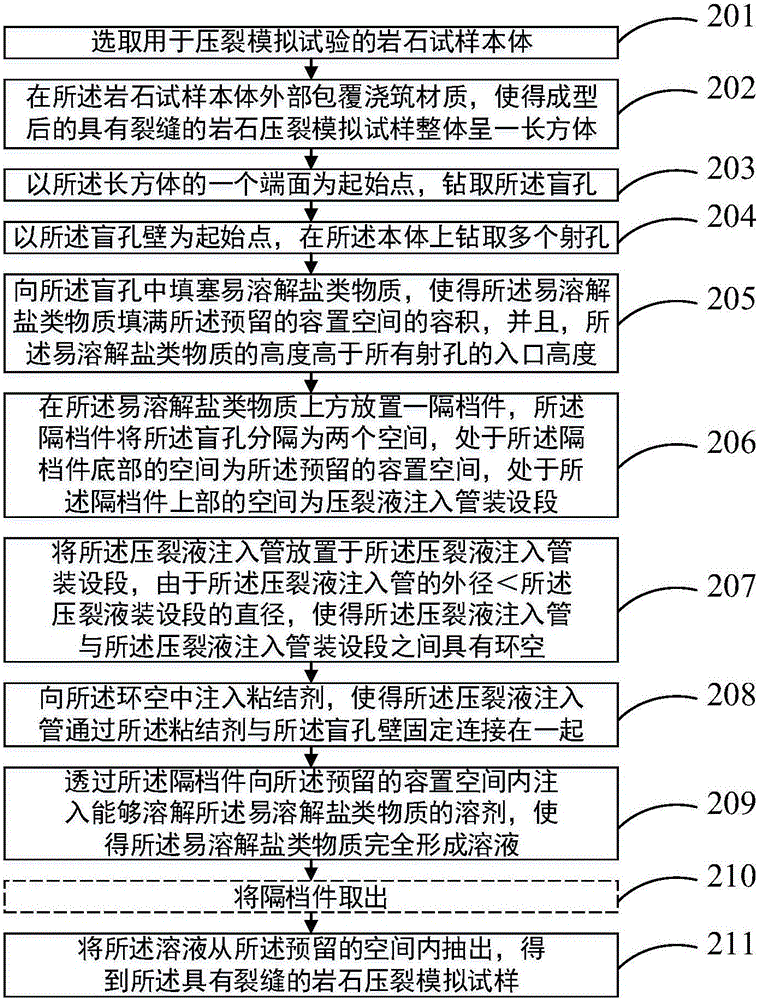

[0067] See attached figure 2 , the preparation method of the rock fracturing simulation sample with cracks provided by the second embodiment of the present invention comprises the following steps:

[0068] Step 201: selecting a rock sample body for a fracturing simulation test;

[0069] Step 202: Covering and pouring materials on the outside of the rock sample body, so that the formed rock fracturing simulation sample with cracks is a cuboid as a whole;

[0070] Step 203: taking one end face of the cuboid as the starting point, drilling a blind hole;

[0071] Step 204: taking the blind hole wall as the starting point, drilling a plurality of perforations on the body;

[0072] Step 205: Filling easily soluble salts into the blind holes so that the easily soluble salts fill up the volume of the reserved accommodating space, and the height of the easily soluble salts is higher than the entrance heights of all perforations;

[0073] Step 206: Place a spacer above the easily so...

Embodiment 3

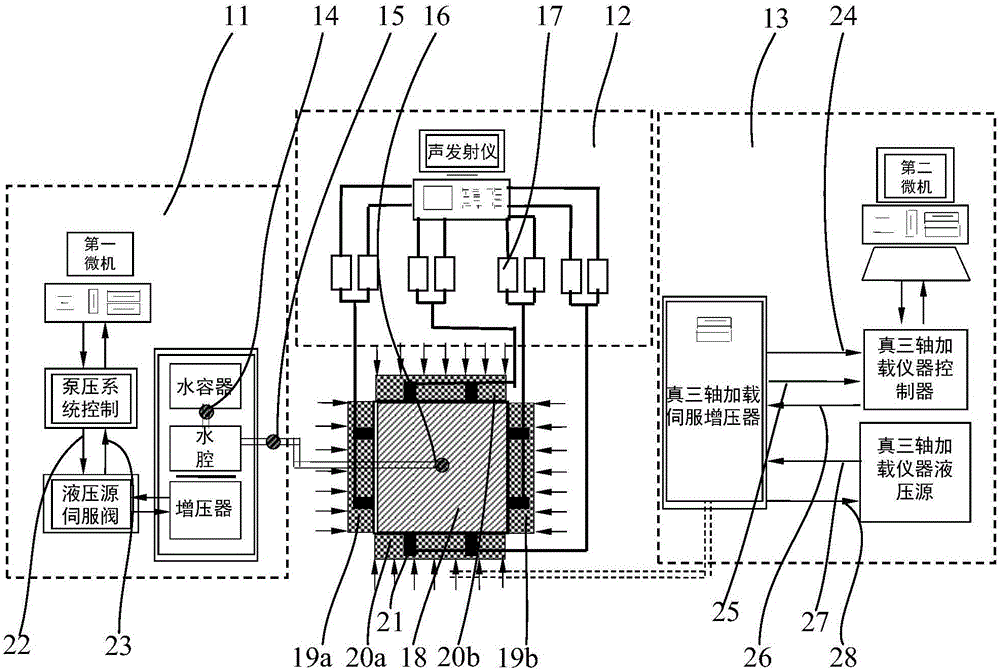

[0089] See attached image 3The rock fracturing simulation test device with cracks provided by Embodiment 3 of the present invention includes a true triaxial loading servo booster, a first set of loading plates 18a, 18b (wherein, 18b is not shown), a second set of loading plates 19a , 19b, the third group of loading plates 20a, 20b, the detection device, and the rock fracturing simulation sample with cracks provided by the present invention. The first group of loading plates 18a, 18b (wherein, 18b is not shown) is arranged on the corresponding face of the first group of cuboid, and the second group of loading plates 19a, 19b is arranged on the corresponding face of the second group of cuboid, and the third group of loading The plates 20a, 20b are arranged on the corresponding surfaces of the third group of cuboids, wherein the loading plate 18a loaded above the fracturing fluid injection pipe 6 is provided with a through hole 16 for the fracturing fluid injection pipe 6 to com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com