Preparation apparatus and preparation method for gel polymer lithium ion battery

A technology of lithium-ion batteries and gel polymers, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems such as many disadvantages of the thermal polymerization process and poor battery reliability, and achieve improved battery reliability, Improved reliability and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

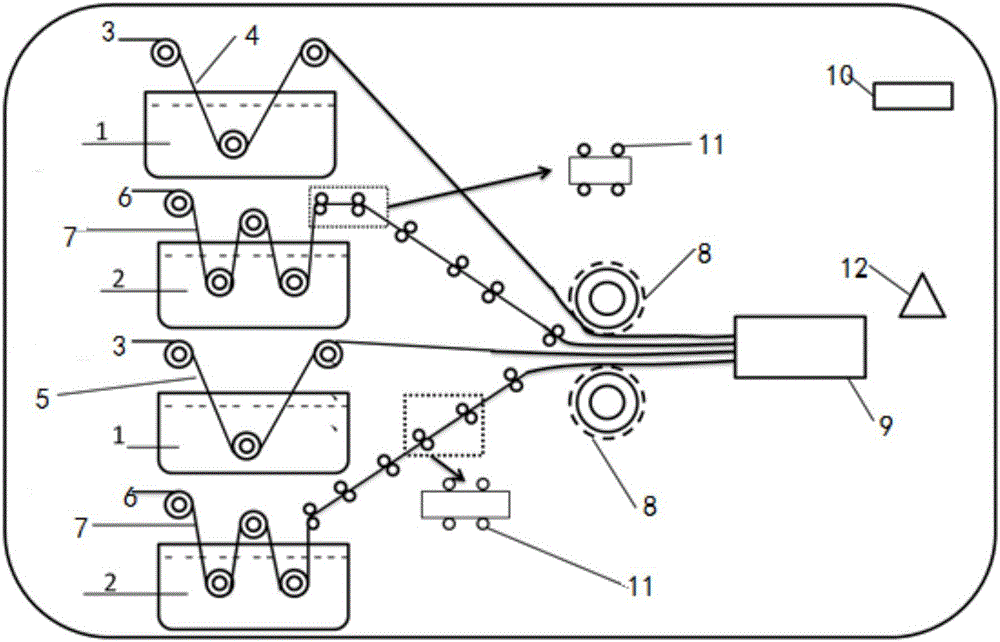

[0040] In this embodiment, a preparation device for a gel polymer lithium-ion battery is provided, please refer to figure 1 , figure 1 It is the structural diagram of the preparation device of the gel polymer lithium ion battery in the embodiment of the present application, such as figure 1 As shown, the device includes:

[0041] A container group, the container group comprising: two first containers 1 and two second containers 2, electrolyte solution is housed in the two first containers 1; gel is housed in the two second containers 2 Electrolyte precursor fluid;

[0042] Two sets of first pulley sets 3, the two sets of first pulley sets 3 are respectively wound with a positive pole piece 4 and a negative pole piece 5; the two sets of first pulley sets 3 are partially located in the two sets of first containers 1, When the two sets of first pulley sets 3 rotate, the positive pole piece 4 and the negative pole piece 5 are driven to soak in the electrolyte;

[0043]Two sets...

Embodiment 2

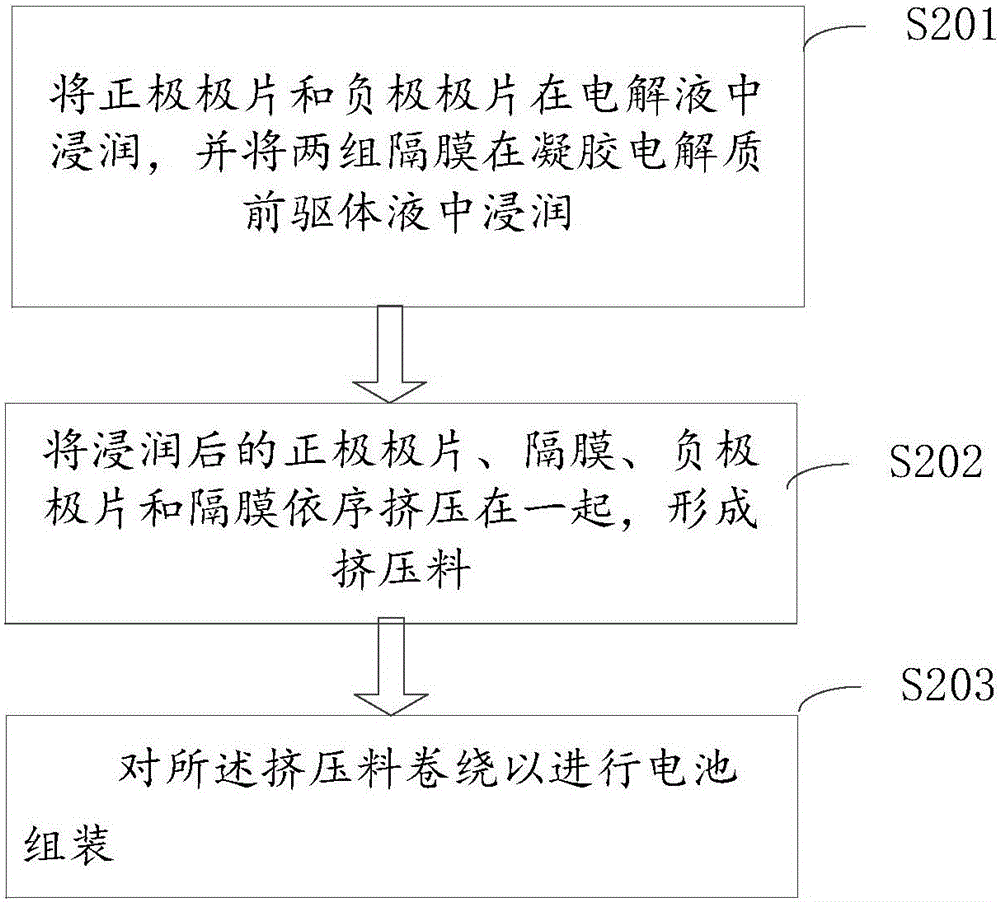

[0069] Provide a kind of preparation method of gel polymer lithium ion battery in this embodiment, please refer to figure 2 , figure 2 It is a flow chart of the preparation method of the gel polymer lithium ion battery in the embodiment of the present application, such as figure 2 As shown, the method includes:

[0070] Step S201, soaking the positive pole piece and the negative pole piece in the electrolyte, and soaking the two sets of separators in the gel electrolyte precursor liquid;

[0071] Step S202, extruding the infiltrated positive electrode sheet, separator, negative electrode sheet and separator together in sequence to form an extrusion material;

[0072] Step S203, winding the extruded material for battery assembly.

[0073] In the embodiment of the present application, before soaking the positive pole piece and the negative pole piece in the electrolyte, it further includes: performing dewatering and dust removal treatment on the positive pole piece and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com