Bionic super-hydrophobic surface, and production method and drag reduction method thereof

A super-hydrophobic surface and bionic technology, applied in the field of high-speed and low-consumption underwater vehicles, can solve the problems of high production and maintenance costs, low drag reduction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

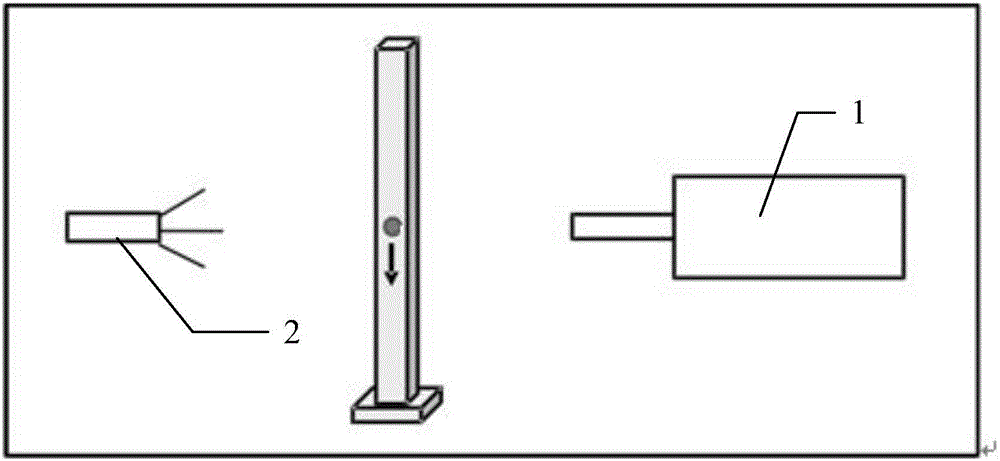

Image

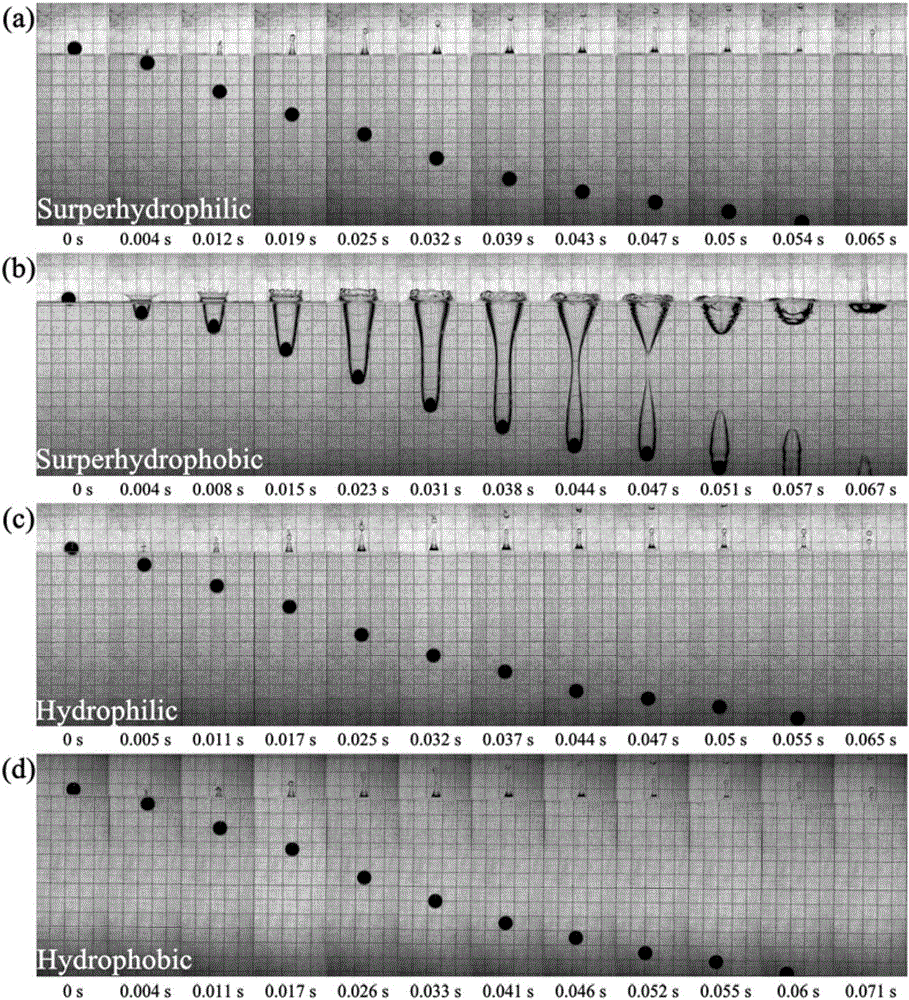

Examples

preparation example Construction

[0039] The method for preparing the above-mentioned bionic super-hydrophobic surface provided by the present invention uses the above-mentioned one-time soaking method to prepare a bionic super-hydrophobic surface with a micro-nano structure, specifically comprising:

[0040] The first step, the cleaning of the surface of the spheroid;

[0041] The second step, the preparation of corrosion solution;

[0042] The third step is the corrosion of the spheroid;

[0043] The fourth step, spheroid hydrophobization treatment;

[0044] The fifth step is to dry the hydrophobized spheres and save them for future use.

[0045] The first step is further specifically to use 0.2-2mol / L sodium hydroxide solution to remove oil stains on the surface of the sphere, 0.2-2mol / L hydrochloric acid solution to wash off the sodium hydroxide solution contaminated on the surface of the sphere in the previous step, The surface of the sphere was ultrasonically cleaned with acetone, then cleaned with ab...

Embodiment 1

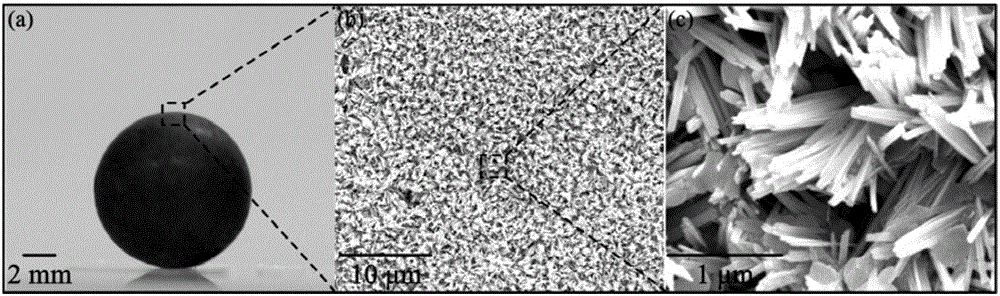

[0061] Example 1 Bionic drag-reducing micro-nano structured surface

[0062] The surface of the copper ball was ultrasonically cleaned with sodium hydroxide solution, hydrochloric acid solution, and acetone, then cleaned with ethanol, and finally cleaned with deionized water, and dried for later use. The mixed solution of sodium hydroxide and ammonium persulfate was used as the corrosion solution. Solution, the amount of sodium hydroxide in 1L corrosion solution is 3mol, the amount of ammonium persulfate is 0.5mol, and the cleaned copper ball is immersed in the prepared mixed solution of sodium hydroxide and ammonium persulfate for corrosion , the corrosion time is 10min, and then the surface corrosion solution is cleaned with deionized water, and then soaked in ethanol for later use to obtain a bionic drag-reducing micro-nano structure surface, and the third step is hydrophobic The final copper ball is subjected to hydrophobization treatment to obtain a bionic drag-reducing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com