Triethanolamine-modified cement grinding aid and preparation method thereof

A technology of cement grinding aid and triethanolamine, which is applied in the field of triethanolamine modified cement grinding aid and its preparation, can solve the problems of high cost, reduced strength, high price of triethanolamine, etc., to reduce surface energy, improve fluidity, The effect of increasing the output per hour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

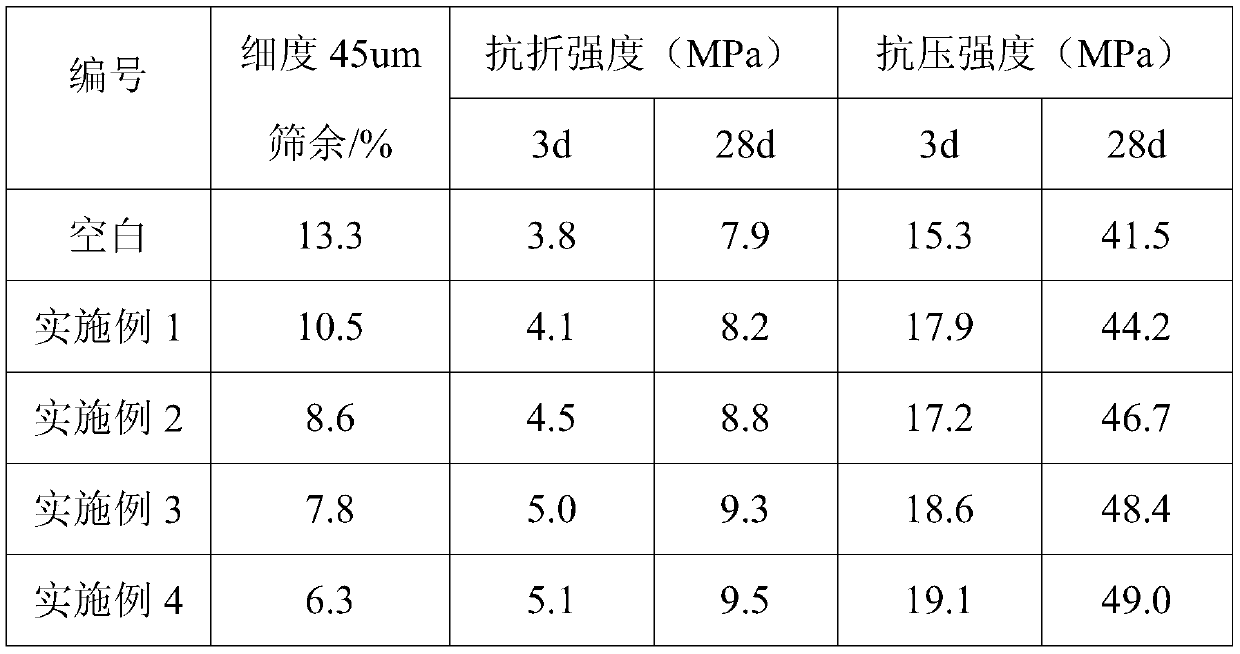

Examples

Embodiment 1

[0023] A kind of triethanolamine modified cement grinding aid, its raw material is composed of: modified glycerin-sulfated-triethanolamine 5%, sodium acetate 5%, molasses 3%, sodium thiosulfate 11%, balance is water, The total amount is 100%; said percentages are mass percentages. Its preparation of described modified triethanolamine comprises the following steps:

[0024] Reaction with triethanolamine, ammonium sulfate and glycerol with a molar ratio of 1:1:1: add triethanolamine (55g, 0.36mol), ammonium sulfate (47.6g, 0.36mol) and glycerol (33g, 0.36mol) in a three-neck round bottom flask ) stirring, add the catalyst before heating up, add the catalyst concentrated sulfuric acid (5% of the total mass of the reactant) 6.78g slowly dropwise, heat to 80°C, after the 5h reaction finishes, cool down and remove moisture by distillation under reduced pressure to obtain modified glycerin-sulfuric acid Esterification - modified triethanolamine.

[0025] The percentages are all per...

Embodiment 2

[0027] A kind of triethanolamine modified cement grinding aid, its raw material is composed of: modified glycerin-sulfated-triethanolamine 10%, sodium acetate 7%, molasses 4%, sodium thiosulfate 15%, balance is water, The total amount is 100%; said percentages are mass percentages. Its preparation of described modified triethanolamine comprises the following steps:

[0028] Reaction with triethanolamine, ammonium sulfate and glycerol with a molar ratio of 1:1:1: add triethanolamine (55g, 0.36mol), ammonium sulfate (47.6g, 0.36mol) and glycerol (33g, 0.36mol) in a three-neck round bottom flask ) stirring, add catalyst before heating up, add catalyst concentrated sulfuric acid (6% of reactant total mass) 8.14g slowly dropwise, heat to 85 ℃, after 4h reaction finishes, cool down and remove moisture by decompression distillation to obtain modified glycerin-sulfuric acid Esterification - modified triethanolamine.

[0029] The percentages are all percentages by mass. According to ...

Embodiment 3

[0031] A kind of triethanolamine modified cement grinding aid, its raw material is composed of: modified glycerin-sulfated-triethanolamine 13%, sodium acetate 6%, molasses 4%, sodium thiosulfate 16%, balance is water, The total amount is 100%; said percentages are mass percentages. Its preparation of described modified triethanolamine comprises the following steps:

[0032] Reaction with triethanolamine, ammonium sulfate and glycerol with a molar ratio of 1:1:1: add triethanolamine (55g, 0.36mol), ammonium sulfate (47.6g, 0.36mol) and glycerol (33g, 0.36mol) in a three-neck round bottom flask ) stirring, add catalyst before heating up, add catalyst concentrated sulfuric acid (7% of reactant total mass) 9.49g slowly dropwise, heat to 88 ℃, after 3h reaction finishes, cool down and decompress to remove moisture to obtain modified glycerin-sulfuric acid Esterification - modified triethanolamine.

[0033] The percentages are all percentages by mass. According to the formula rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com