Modified cement grinding auxiliary agent and preparation method thereof

A cement grinding aid and modification technology, which is applied in the field of modified cement grinding aid and its preparation, can solve the problems of not being suitable for the actual production process of cement, the high price of triethanolamine, and the increase of cement production cost, etc. Hourly output, shortening of coagulation time, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

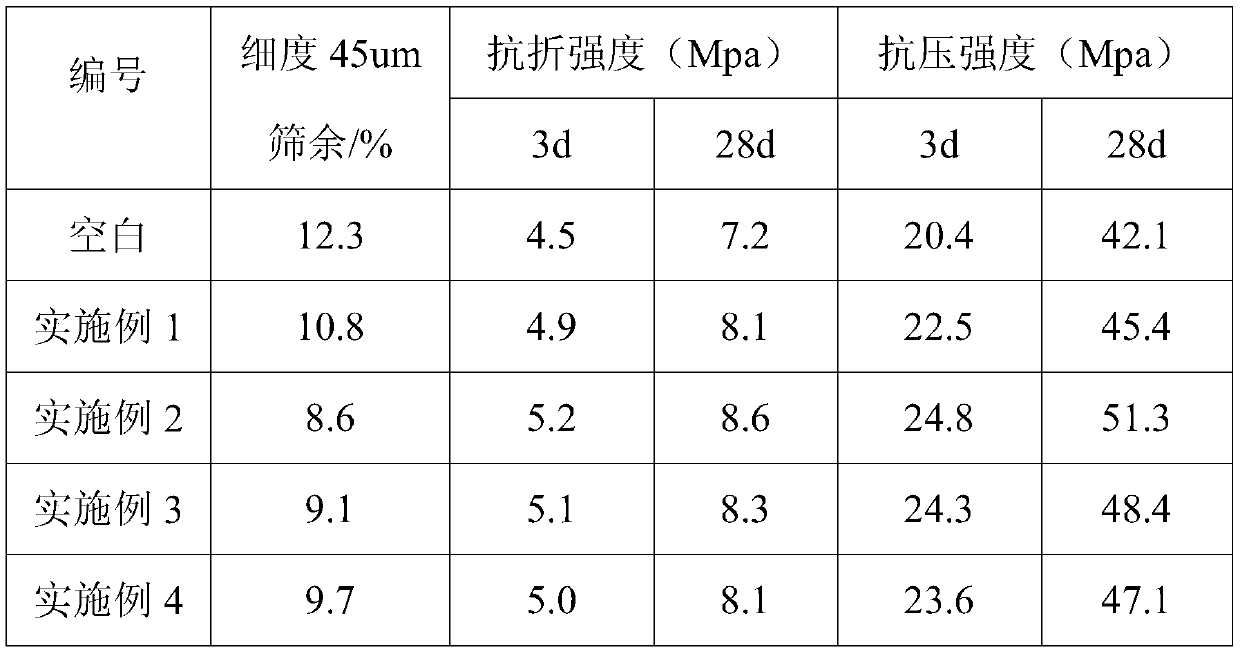

Examples

Embodiment 1

[0022] A modified cement grinding aid, its raw materials are composed of: phosphoric acid-glycerol modified triethanolamine 7%, activator 0.5%, polyol 15%, molasses 3%, sodium thiosulfate 7%, sodium sulfate 3% , sodium acetate 2%, the balance is water, the total amount is 100%;

[0023] Its preparation of described phosphoric acid-glycerol modified triethanolamine comprises the following steps:

[0024] Reaction with triethanolamine, glycerol and phosphoric acid with a molar ratio of 1:1:1: add triethanolamine (31.1g, 0.21mol), glycerol (43g, 0.21mol) and phosphoric acid (19.95g, 0.21mol) into a 250ml three-neck round bottom flask ) stirring, adding catalyst before heating up, adding catalyst concentrated sulfuric acid (1% of the total mass of the reactant) and slowly adding dropwise, heating to 120° C., after 3 hours of reaction, cooling down to obtain triethanolamine phosphate glycerol modified product.

[0025] The percentages are all percentages by mass. According to the ...

Embodiment 2

[0027] A modified cement grinding aid, the raw materials of which consist of: phosphoric acid-glycerin modified triethanolamine 15%, activator 0.8%, polyol 34%, molasses 10%, sodium thiosulfate 15%, sodium sulfate 5% , sodium acetate 8%, the balance is water, the total amount is 100%;

[0028] Its preparation of described phosphoric acid-glycerol modified triethanolamine comprises the following steps:

[0029] Reaction with triethanolamine, glycerol and phosphoric acid with a molar ratio of 1:1:1: add triethanolamine (31.1g, 0.21mol), glycerol (43g, 0.21mol) and phosphoric acid (19.95g, 0.21mol) into a 250ml three-neck round bottom flask ) stirring, add the catalyst before heating up, add the catalyst concentrated sulfuric acid (3% of the total mass of the reactant) slowly dropwise, heat to 140°C, after 6h of reaction, cool down to obtain triethanolamine phosphate glycerol modified product.

[0030] The percentages are all percentages by mass. According to the proportion of t...

Embodiment 3

[0032] A modified cement grinding aid, its raw materials are composed of: phosphoric acid-glycerin modified triethanolamine 12%, activator 0.5%, polyol 17%, molasses 3%, sodium thiosulfate 9%, sodium sulfate 4% , sodium acetate 6%, the balance is water, the total amount is 100%;

[0033] Its preparation of described phosphoric acid-glycerol modified triethanolamine comprises the following steps:

[0034] Reaction with triethanolamine, glycerol and phosphoric acid with a molar ratio of 1:1:1: add triethanolamine (31.1g, 0.21mol), glycerol (43g, 0.21mol) and phosphoric acid (19.95g, 0.21mol) into a 250ml three-neck round bottom flask ) stirring, add the catalyst before heating up, add the catalyst concentrated sulfuric acid (2% of the total mass of the reactants) slowly dropwise, heat to 130° C., after 5 hours of reaction, cool down to obtain triethanolamine phosphate glycerol modified product.

[0035] The percentages are all percentages by mass. According to the proportion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com