Special grinding aid for conductive cement and preparation method and application thereof

A technology of conductive cement and grinding aid, applied in the field of conductive cement production, can solve the problems of the reduction of tensile strength, cracking strength and toughness of the cement body, and achieve increased production per hour, good corrosion resistance, and good chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

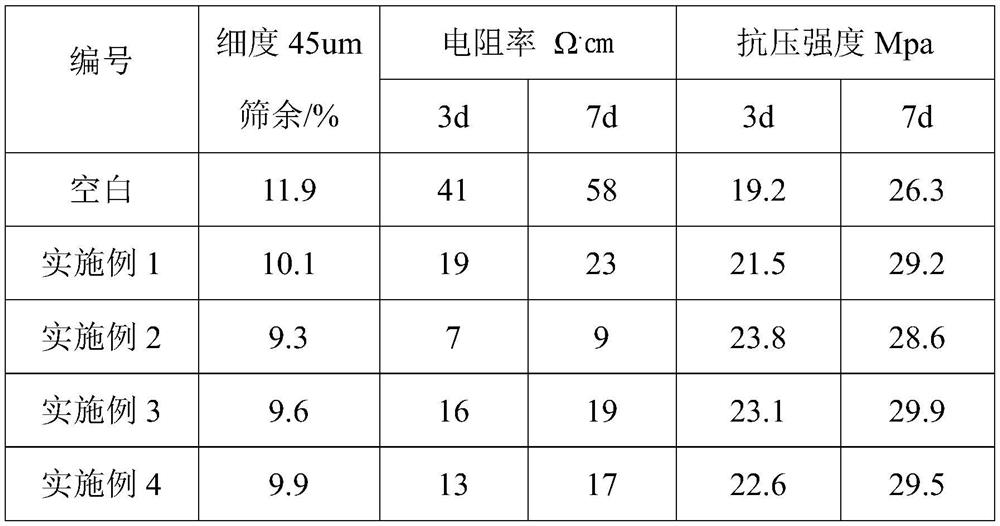

Examples

Embodiment 1

[0028] A special grinding aid for conductive cement, its raw material composition is: 17% of grinding aid mother liquor, 3% of conductive polyaniline, 5% of polystyrene, 8% of basalt fiber, 4% of iron ore powder, 3% of polyvinylpyrrolidone %, the balance is conductive fly ash, the total amount is 100%;

[0029] The percentages are all percentages by mass. According to the formula ratio, mix the grinding aid mother liquor, conductive polyaniline, polystyrene, basalt fiber, iron ore powder, polyvinylpyrrolidone and conductive fly ash evenly to obtain , product 1.

Embodiment 2

[0031] A special grinding aid for conductive cement. Its raw materials are: 25% of grinding aid mother liquor, 7% of conductive polyaniline, 9% of polystyrene, 15% of basalt fiber, 9% of iron ore powder, and 5% of polyvinylpyrrolidone. %, the balance is conductive fly ash, the total amount is 100%;

[0032] The percentages are all percentages by mass. According to the formula ratio, mix the grinding aid mother liquor, conductive polyaniline, polystyrene, basalt fiber, iron ore powder, polyvinylpyrrolidone and conductive fly ash evenly to obtain , Product 2.

Embodiment 3

[0034] A special grinding aid for conductive cement. Its raw materials are: 20% of mother liquid of grinding aid, 5% of conductive polyaniline, 7% of polystyrene, 11% of basalt fiber, 7% of iron ore powder, and 4% of polyvinylpyrrolidone. %, the balance is conductive fly ash, the total amount is 100%;

[0035] The percentages are all percentages by mass. According to the formula ratio, mix the grinding aid mother liquor, conductive polyaniline, polystyrene, basalt fiber, iron ore powder, polyvinylpyrrolidone and conductive fly ash evenly to obtain , Product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com