Steel plate shear wall

A steel plate shear wall and shear wall technology, applied in the field of steel plate shear walls, can solve problems such as increasing the complexity of steel plate shear walls, and achieve the effects of avoiding welding residual stress, reducing construction time and procedures, and improving deformation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] The specific assembly implementation method of the bionic steel plate shear wall of the present invention is as follows:

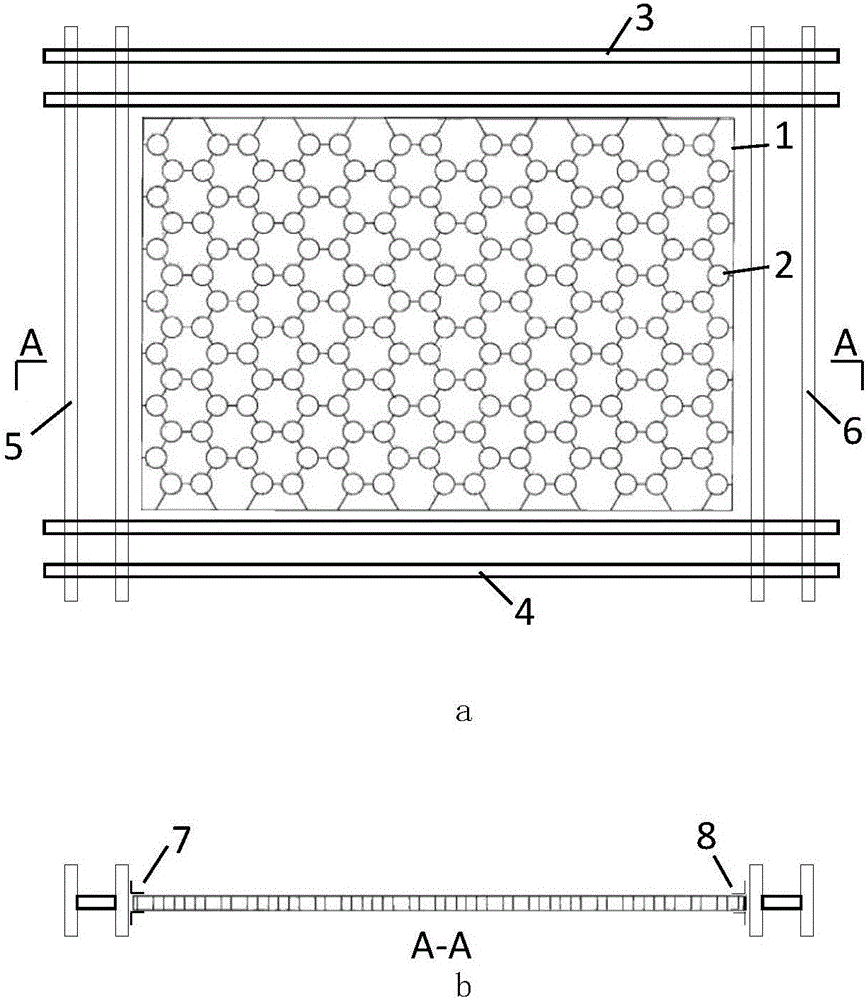

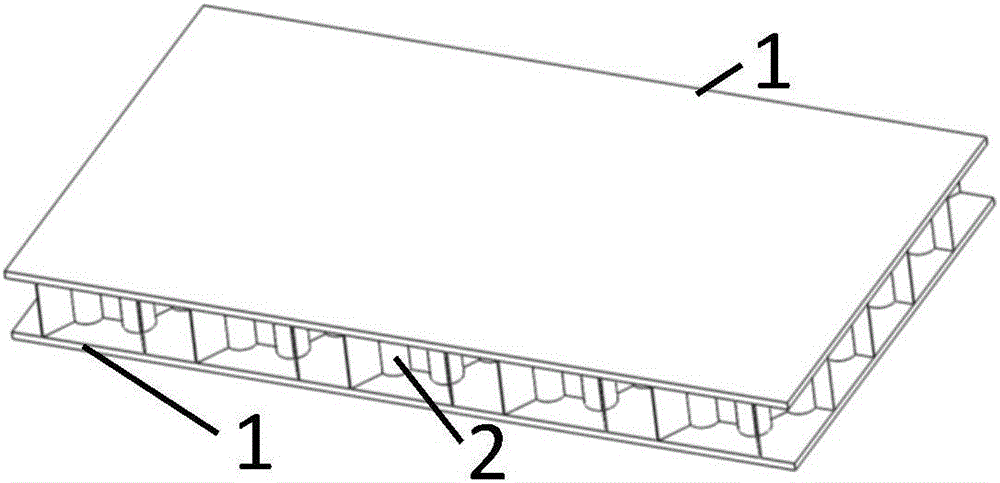

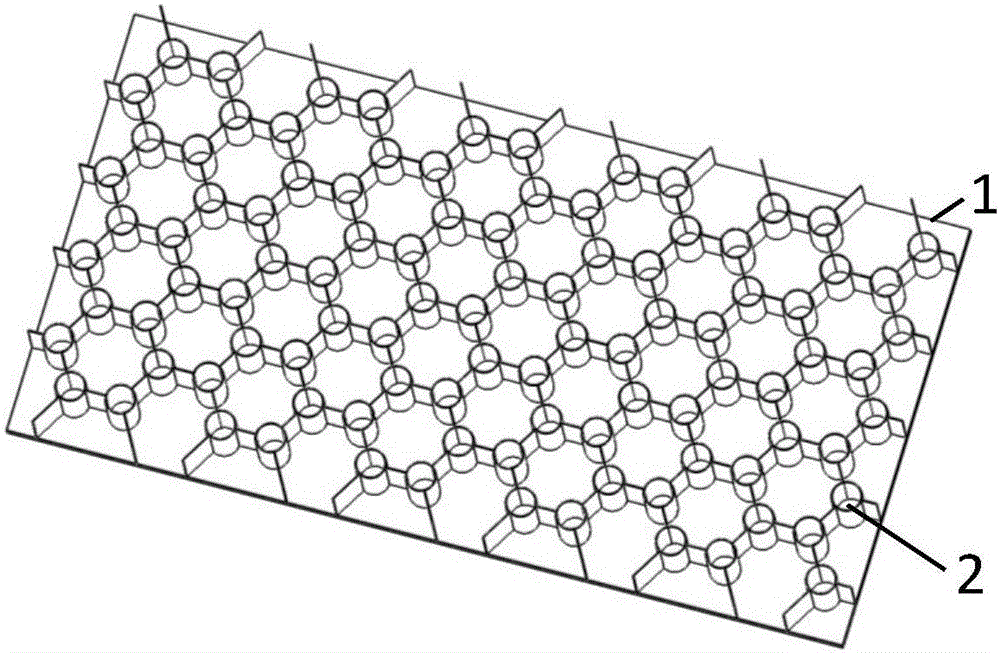

[0043] Schematic diagram of the bionic steel plate shear wall model and its detailed structure figure 1 ,2,3,4 shown. According to the commonly used building shear wall size and stress conditions, this manual reserves the bolt hole spacing of the steel plates on both sides and the interlayer according to the seismic fortification intensity of the area. The first step is to press the unit polygon grille with semicircle into the Figure 5 As shown, use bolts to connect and install (the bionic honeycomb core layer has a variety of manufacturing processes, this specific embodiment only provides one as an example, and it can also be connected by adhesive, one-time molding, snap-fit connection, etc.); the second step Fix the A and B steel plates on both sides with bolts, see the assembly process Figure 6 ; The third step is to transport the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com