Cold-formed thin-wall section steel composite sheet steel shear wall

A cold-formed thin-walled section steel and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of reducing the lateral stiffness and bearing capacity of the structure, the limitation of the number of residential floors, and the low energy consumption capacity. Construction cost, excellent seismic performance, and the effect of improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

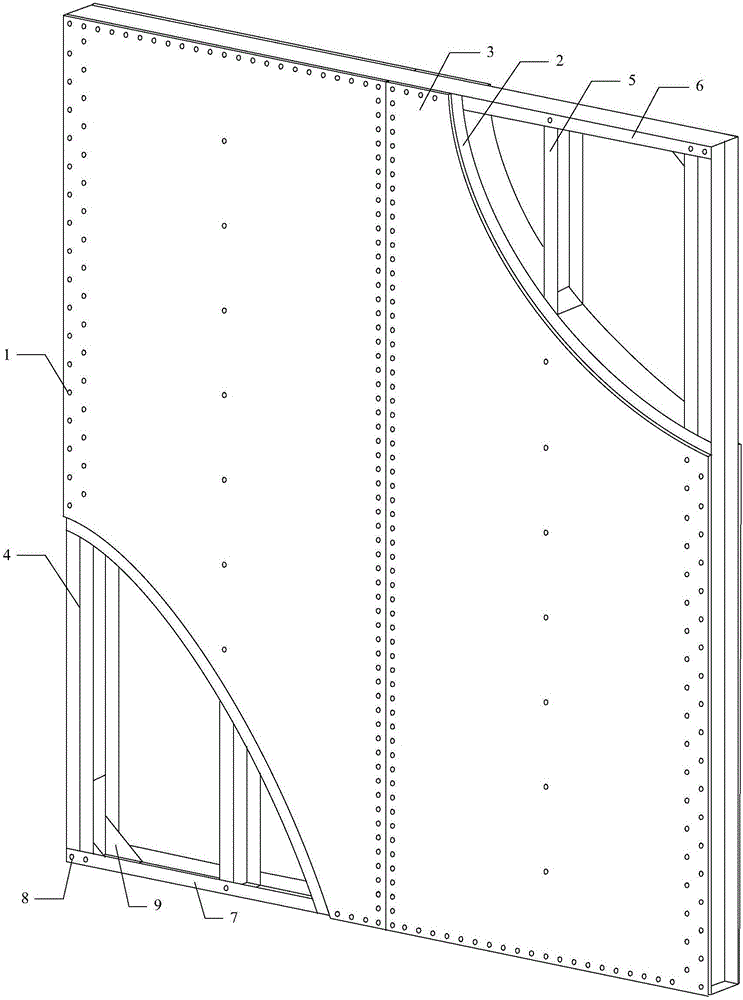

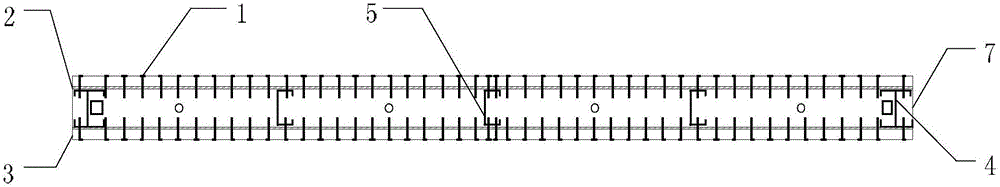

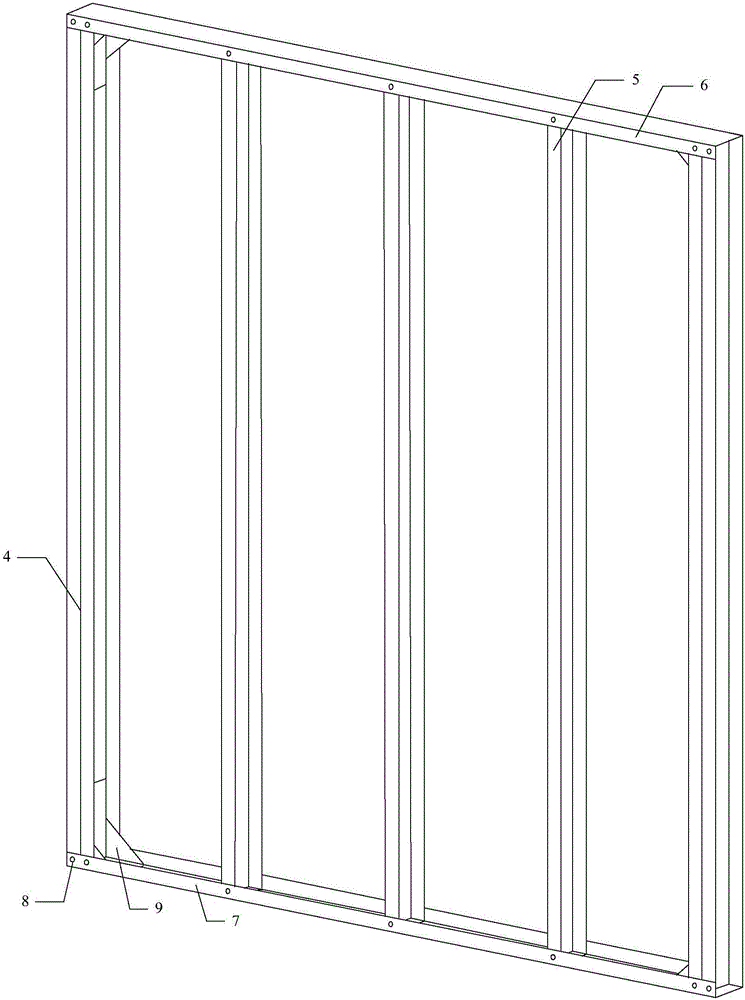

[0031] A cold-formed thin-walled steel composite steel-skin shear wall is composed of a composite steel-skinned wall panel unit and a cold-formed thin-walled steel skeleton unit connected and fixed by self-tapping screws. The bottom layer of each side wall panel unit is steel skin, and the surface layer is paper-faced fireproof gypsum board. The cold-formed thin-walled steel skeleton unit is composed of cold-formed thin-walled steel columns and cold-formed thin-walled steel guide rails connected by self-tapping screws. The four corners of the cold-formed thin-walled steel skeleton unit are provided with anti-pull pieces to connect the side columns with the top guide rail and the bottom guide rail. The wall panel unit and the cold-formed thin-walled steel skeleton unit are connected by self-tapping screws to realize the assembly and splicing of the composite wall.

[0032] The wall panel units on both sides and the middle cold-formed thin-walled steel skeleton unit are fixedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com