Turbocharger compressor volute with noise reduction function

A technology of turbocharger and compressor, applied in machine/engine, mechanical equipment, engine control, etc., can solve the problem of affecting the working life of engine and turbocharger, unstable working state of engine, axial flutter of rotor shaft, etc. To achieve the effect of reducing intake energy loss, reducing intake resistance, and reducing intake loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

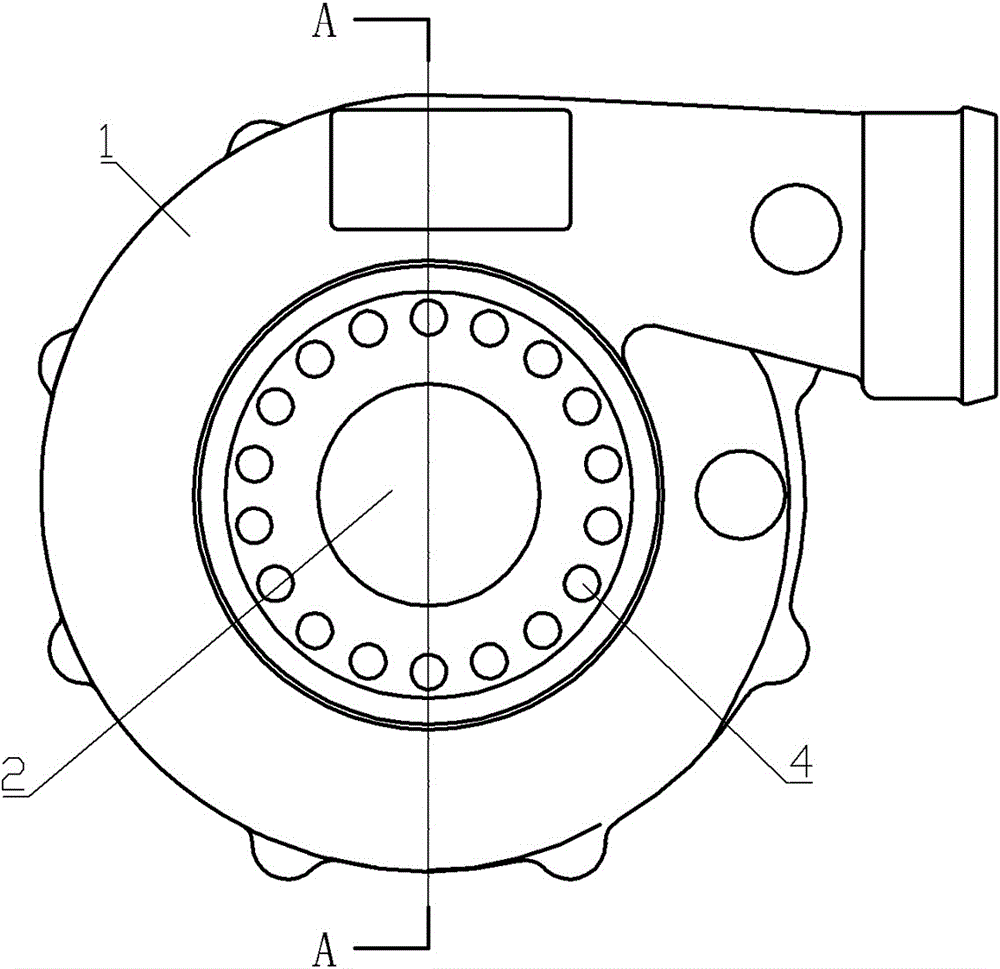

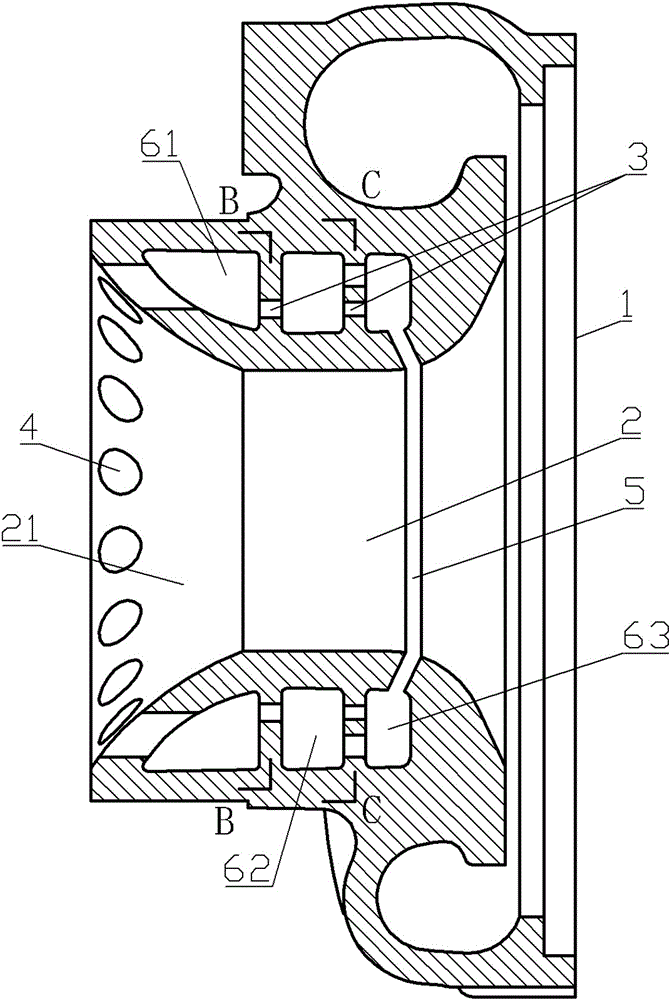

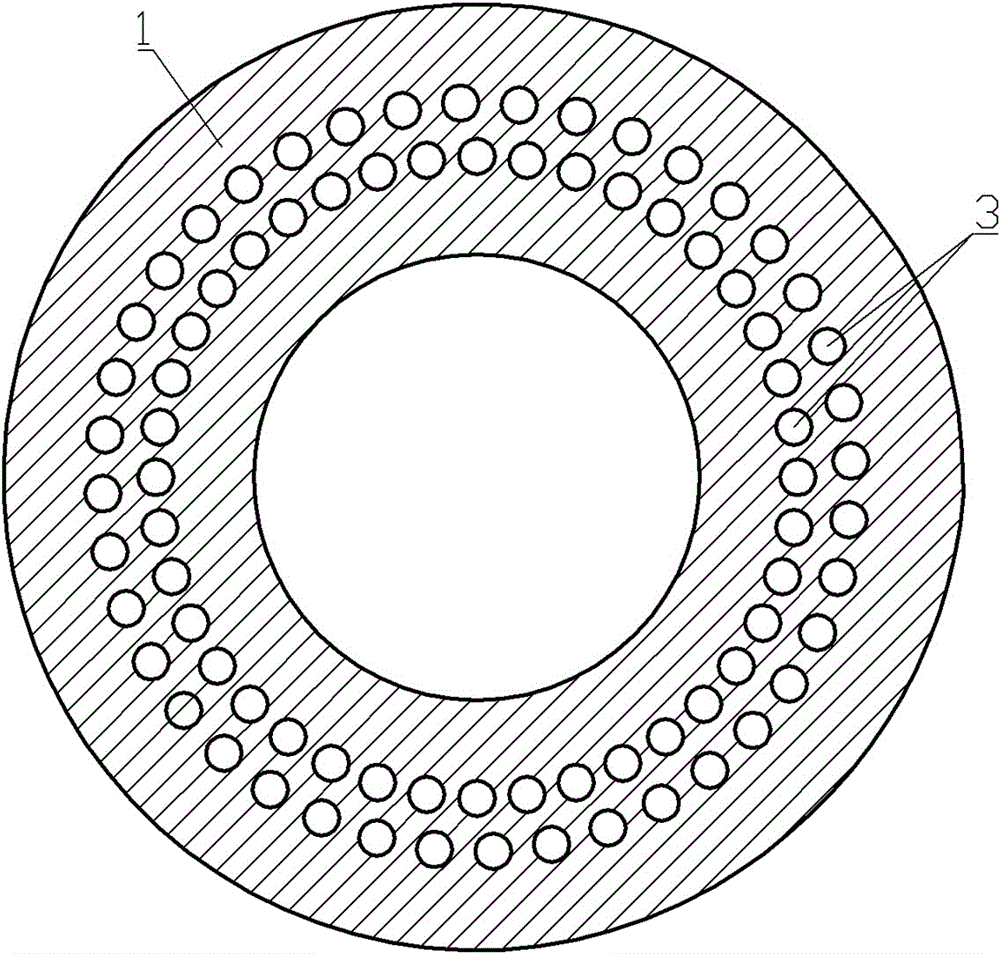

[0021] Such as Figure 1-4 Shown: a turbocharger compressor volute with a noise reduction function, which includes a housing 1 on which an air intake channel 2 with openings at both ends is arranged. The casing 1 is also provided with a plurality of annular mufflers surrounding the air intake passage 2 and arranged at intervals along the axial direction. Adjacent annular sound-absorbing cavities are communicated through a plurality of sound-absorbing holes B3. The wall surface of the air inlet section 21 of the air inlet channel 2 is a shrinking arc surface, and the air inlet section 21 is provided with a plurality of muffler holes A4, and the muffler holes A4 are connected to the annular muffler chamber closest to the air inlet section 21 . The air intake passage 2 is provided with a secondary air intake slot 5 , and the secondary air intake slot 5 communicates with the annular muffler chamber farthest from the air intake section 21 .

[0022] There are three annular sound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com