Shear wall fire exposure testing device under vertical load effect

A vertical load and test device technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, lighting and heating equipment, etc., can solve the problem that the fire test of vertically placed shear walls cannot be realized and cannot be repeated Utilization, temperature rise control and other problems are not accurate enough to achieve the effects of good modifiability, high assembly efficiency, and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

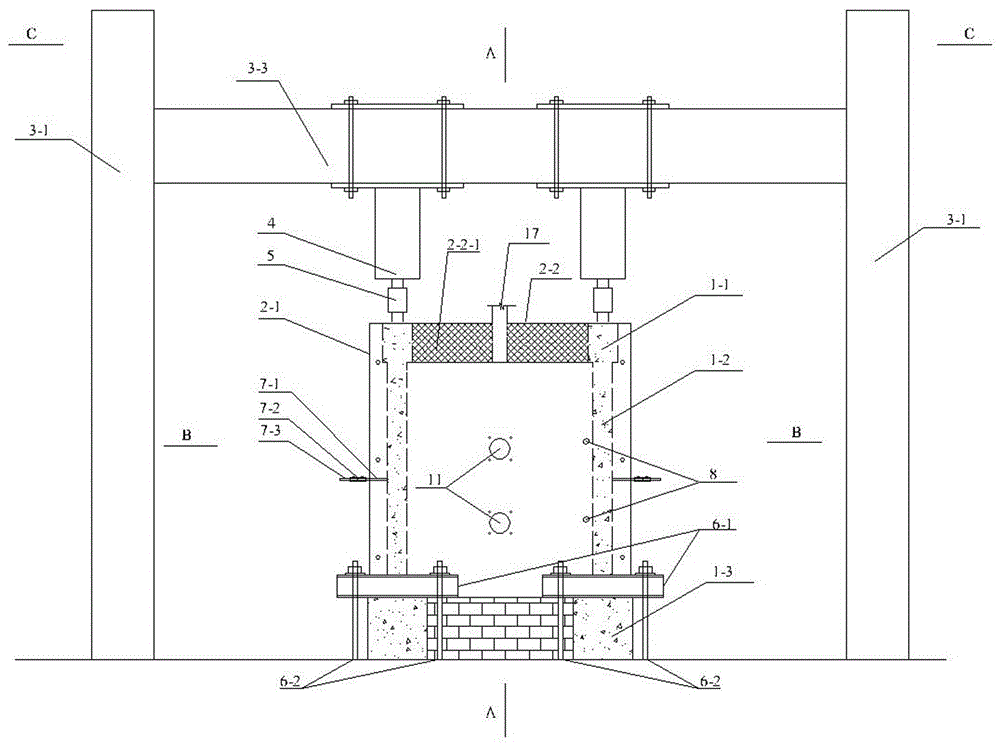

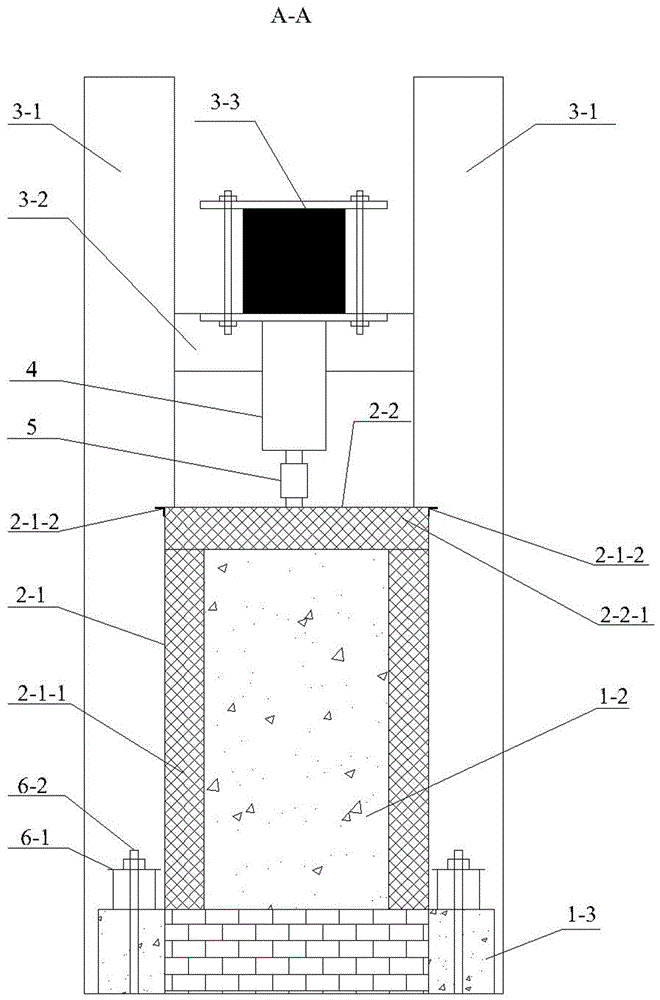

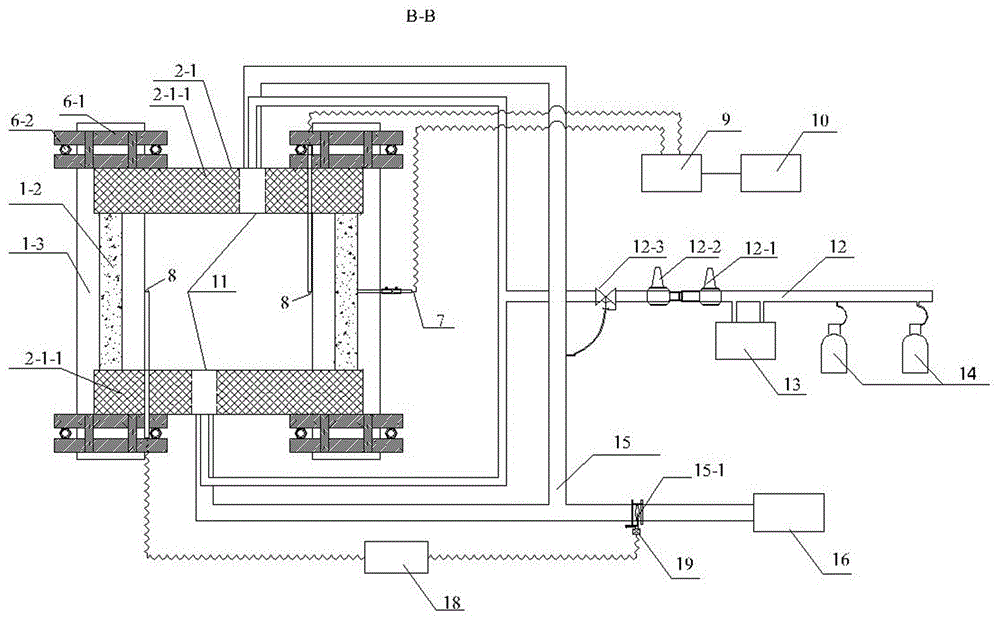

[0024] Embodiment one: if Figure 1-Figure 4 As shown, in this embodiment, the shear wall fire test device under the vertical load includes a furnace body, a loading system, an information collection system, and a combustion control system. The shear wall component 1 includes a shear wall body 1-2, shear wall loading beam 1-1 shear wall bottom pier 1-3, the furnace body consists of two shear wall members 1, furnace side wall 2-1, furnace roof 2-2 using bolts, Assembled by screws, the shear wall body 1-2 and two furnace side walls 2-1 form a vertical box-shaped space, and a furnace roof 2-2 is placed on the top of the vertical box-shaped space, and the furnace side The edge of the steel plate of the wall 2-1 and the furnace roof 2-2 is designed with reserved holes for bolts, and the upper edge of the steel plate of the furnace side wall 2-1 is welded and drilled Angle steel 2-1-2 and the edge of the furnace roof 2-2 are fastened with bolts , the bottom pier 1-3 of the shear wa...

Embodiment 2

[0033] Embodiment two: if Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the furnace body is assembled by four shear wall components 1, furnace side walls 2-1, and furnace roof 2-2 using bolts and screws. As a result, the shear wall body 1-2 and the four L-shaped furnace side walls 2-1 form a box-shaped space, and correspondingly, two reaction frames need to be provided.

[0034] The working process of the present invention is:

[0035] During the test, first build the furnace side wall 2-1 and the furnace roof cover 2-2 according to the size of the fire shear wall specimen 1, and reserve holes and bolts for the thermocouple 8, the burner 11, and the flue 17 hole; then according to the specific embodiment of the furnace body one or two according to the test requirements, the shear wall component 1 and the furnace side wall 2-1 are hoisted in place, and the screw rod passes through the reserved hole on the furnace side wall, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com