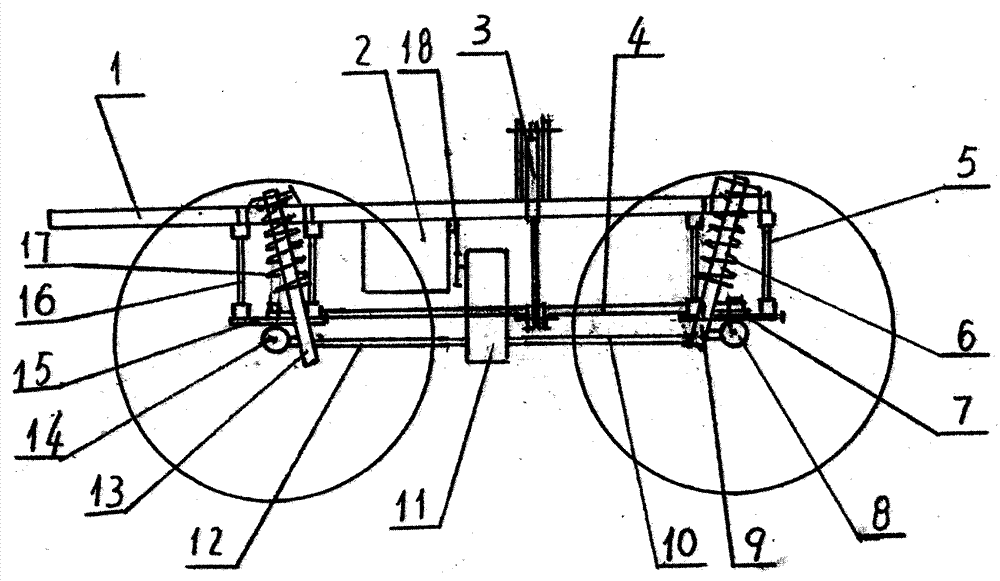

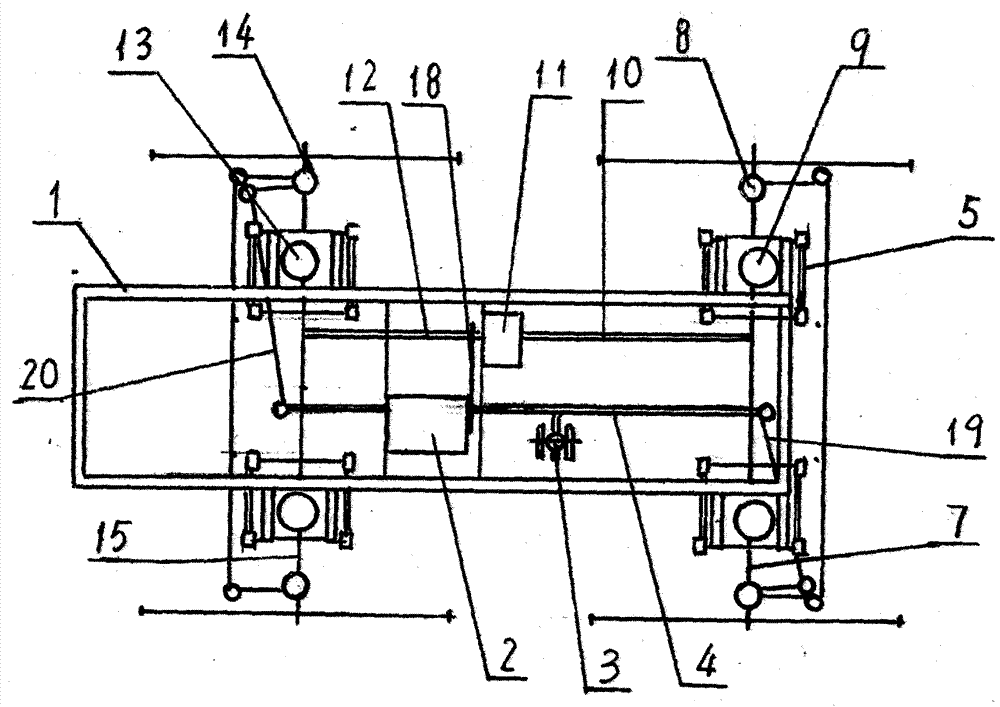

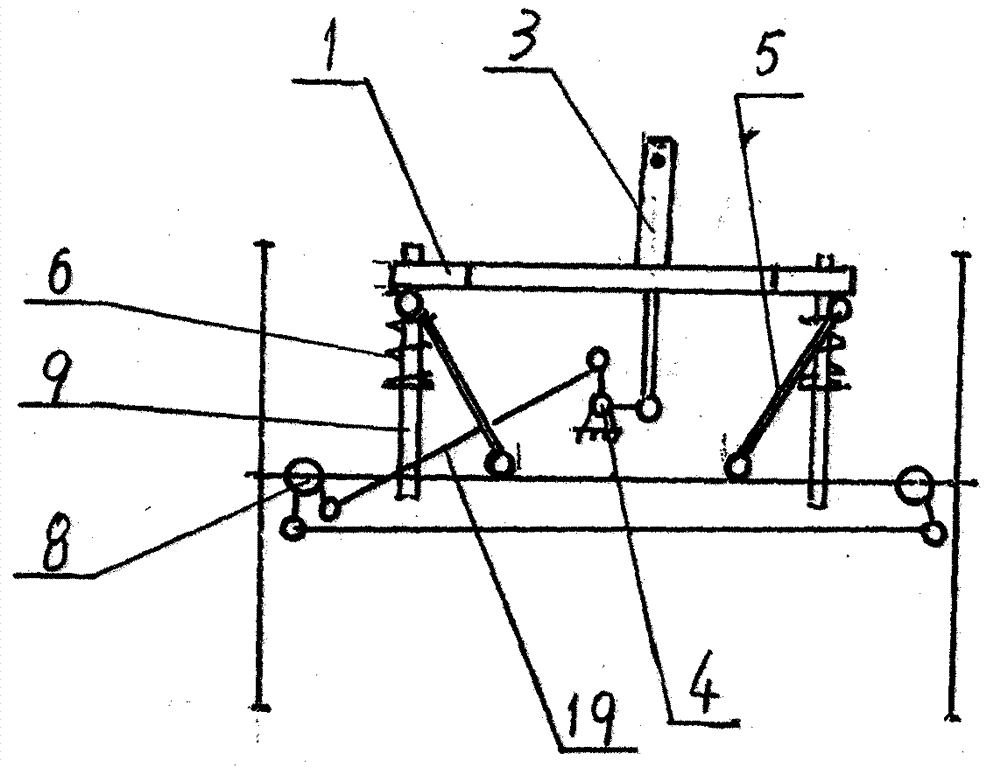

Four-wheel drive rice transplanter self-propelled chassis front and rear wheel steering linkage mechanism

A technology of a linkage mechanism and a rice transplanter, which is applied to the steering mechanism of the deflectable wheel, the steering mechanism, the fluid steering mechanism, etc., can solve the problems of reducing the quality of rice seedling transplanting operations, destroying the flatness of rice fields, and prone to floating seedlings, etc. Achieve the effect of reducing the turning resistance, reliable operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A four-wheel-drive rice transplanter self-propelled chassis front and rear wheel steering linkage mechanism includes a frame welding 1 and a main gear box assembly 2 fitted on the frame welding 1. 1. The front suspension double arms 16 are respectively swingably hingedly installed on the lower right side, and the lower end of the front suspension double arms 16 is hingedly connected with the front axle housing 15 of the front drive axle assembly 14, and the front drive axle assembly 14 hanging is installed on the lower part of the front end of the frame welding 1, and the front hydraulic damping shock absorber 13 of the set front pressure spring 17 is fixed on the front end of the frame welding 1, and the damping of the front hydraulic damping shock absorber 13 The piston rod is fixedly connected to the front half shaft housing 15, the upper end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com