Matte, high-elasticity and low-temperature-resistant PVC hose and preparation method thereof

A high-elasticity, low-temperature-resistant technology, used in hoses, pipes, mechanical equipment, etc., can solve the problems of high price of cross-linked PVC cross-linked resin, inability to meet the needs of high-strength work, and poor weather resistance. Recyclability, good product transparency, and improved low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

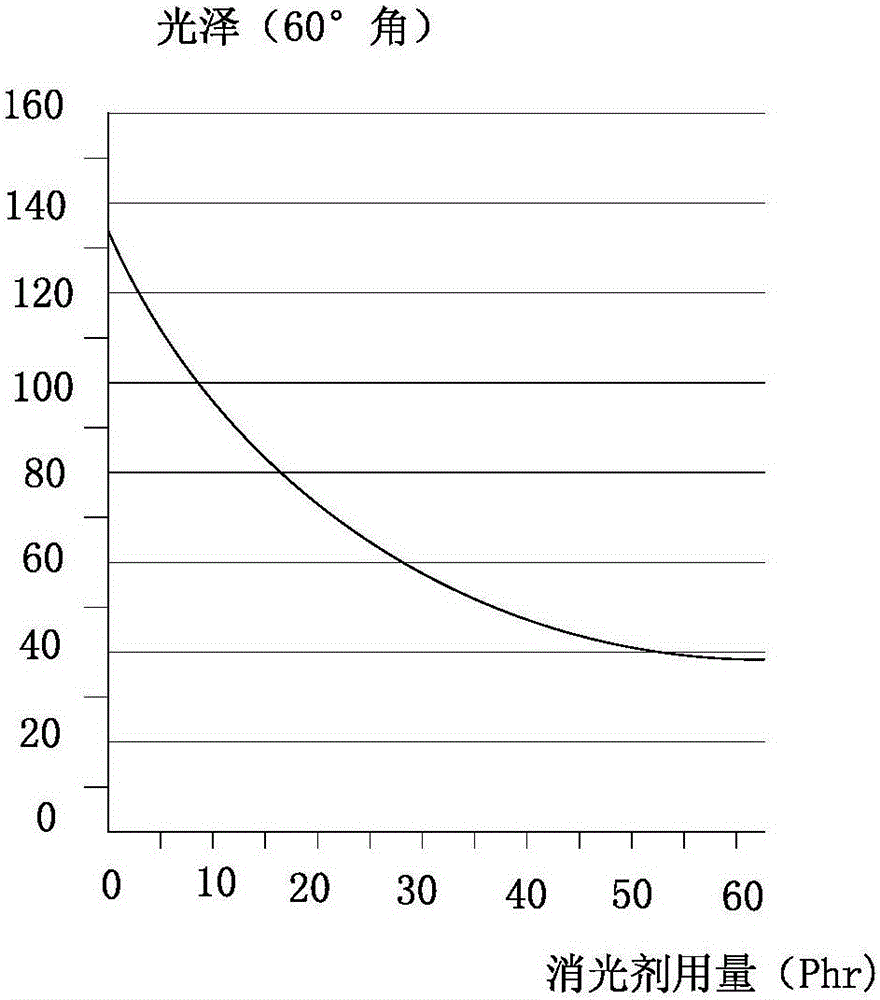

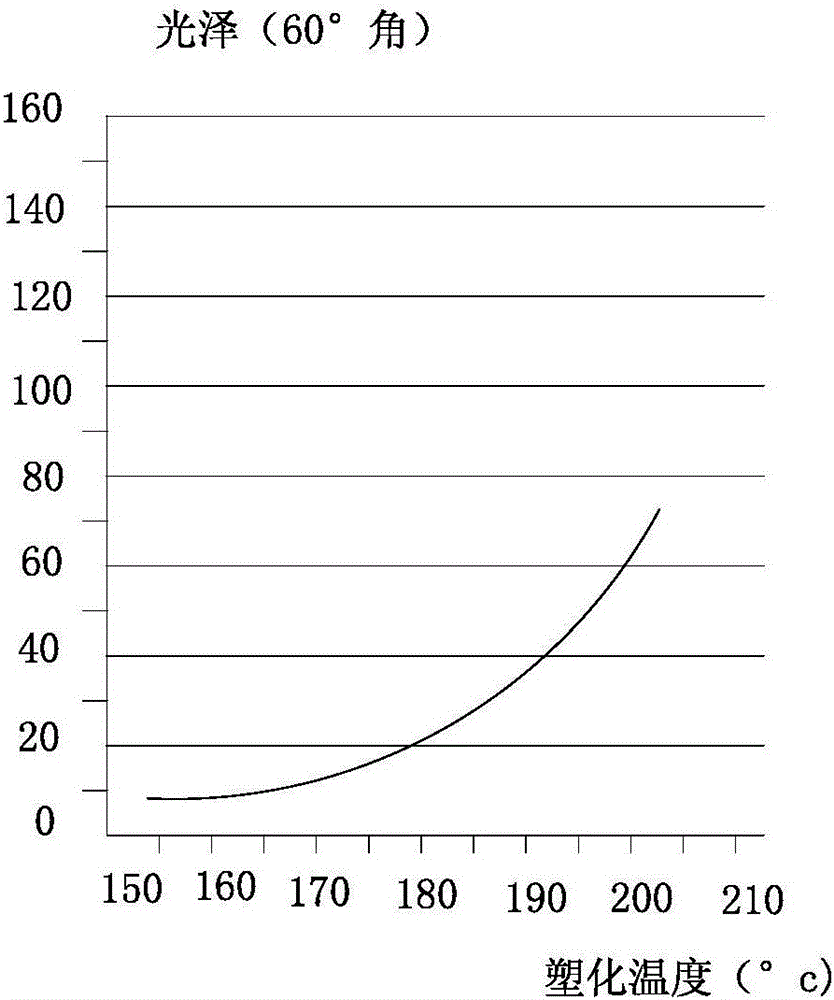

Image

Examples

Embodiment 1

[0038] The formula composition of the inner tube and the outer tube of the matte high-elastic low-temperature-resistant PVC hose is shown in Table 1 and Table 2.

[0039] raw material

parts by mass

Conventional PVC: PVC with high degree of polymerization

70:30

Organic tin heat stabilizer JH-101

2

DINCH plasticizer

30

PVC Low Temperature Modifier (DOA)

5

Impact Modifier ACR

5

UV-326

2

Titanium dioxide

2

Calcium carbonate whiskers (whisker length 50μm)

5

Antioxidant 1076

1

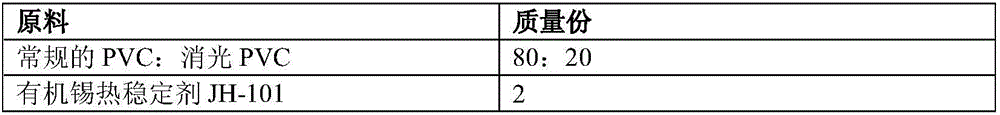

[0040] Table 2: Formula composition of the outer tube of the PVC hose

[0041]

[0042]

Embodiment 2

[0044] The formula composition of the inner tube and the outer tube of the matte high-elastic low-temperature-resistant PVC hose is shown in Table 3 and Table 4.

[0045] raw material

[0046] raw material

Embodiment 3

[0048] The formula composition of the inner tube and the outer tube of the matte high-elastic low-temperature-resistant PVC hose is shown in Table 5 and Table 6.

[0049] raw material

[0050] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whisker length | aaaaa | aaaaa |

| Whisker length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com