Method of preparing oxide/metal magnetic heterojunction through atomic layer deposition

An atomic layer deposition method and atomic layer deposition technology, applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problem of inability to obtain thin films of thickness and composition height, hindering realization, and impossible to achieve thin films. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

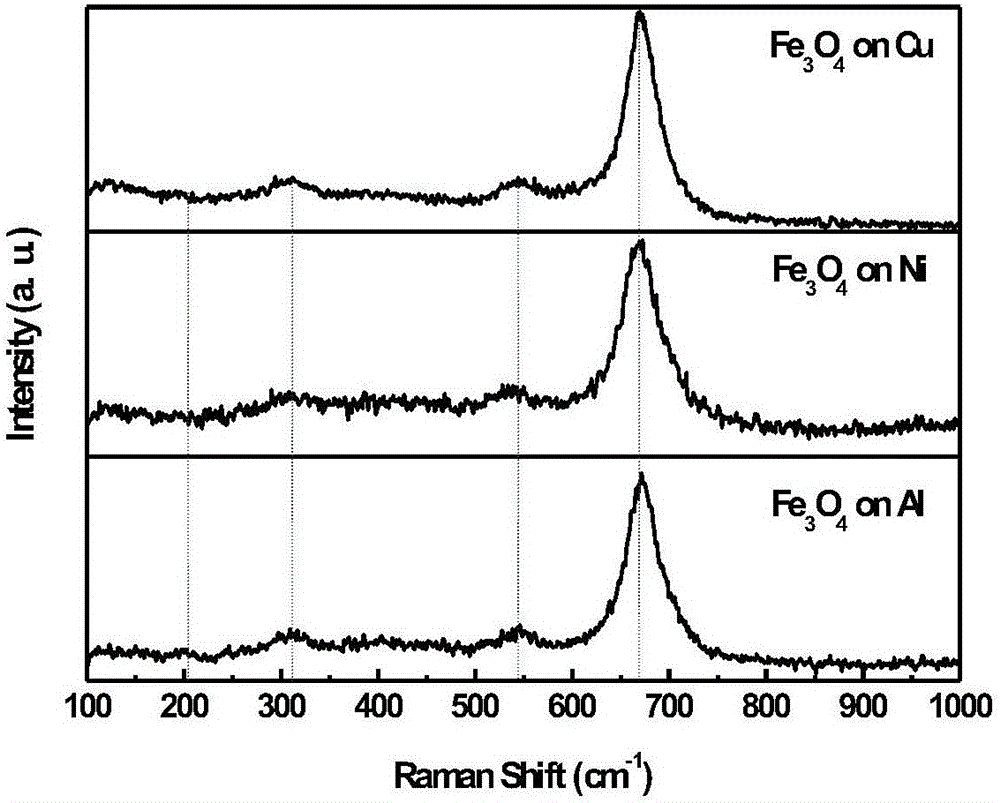

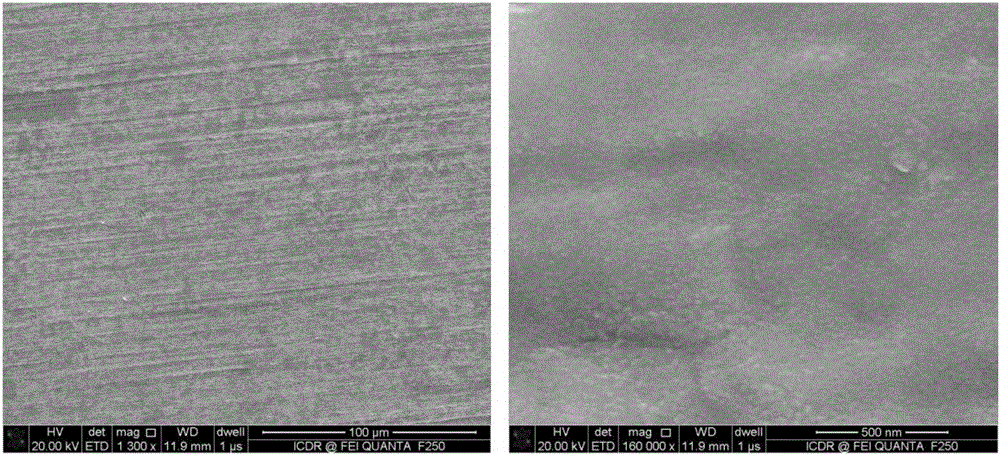

Embodiment 1

[0029] 1), Substrate pretreatment: the Cu substrate required for the experiment is concentrated H at a volume ratio of 2 SO 4 :H 2 o 2 = 1:1 wash solution for 3 minutes, then take the substrate out of the wash solution, rinse with a large amount of deionized water and blow dry with high-purity nitrogen for later use;

[0030] 2) Using ferrocene as the iron source and oxygen as the oxygen source to deposit ferric oxide film. Put the ferrocene into the special solid-state source cylinder of the atomic layer deposition system and heat it to 150°C, and connect the oxygen to the reaction chamber of the atomic layer deposition system through a special pipeline for standby. Before starting the deposition, pre-exhaust the ferrocene source steel cylinder to eliminate the air mixed in the source loading process, and ensure the stability of the ferrocene source pulse and not be oxidized and decomposed during the heating process;

[0031] 3) Send the metal substrate pretreated in step 1...

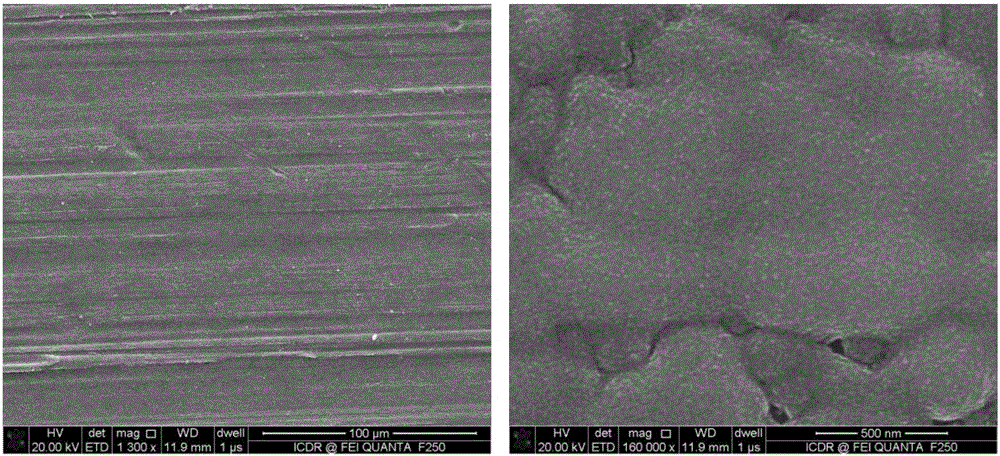

Embodiment 2

[0035] 1), Substrate preparation: the Ni substrate required for the experiment is concentrated H in the volume ratio 2 SO 4 :H 2 o 2 =3:1 washing solution for 5 minutes, then the substrate was taken out from the washing solution, rinsed with a large amount of deionized water and blown dry with nitrogen for later use;

[0036] 2) Using ferrocene as the iron source and oxygen as the oxygen source to deposit ferric oxide film. Put the ferrocene into the special solid-state source cylinder of the atomic layer deposition system and heat it to 160°C, and connect the oxygen to the reaction chamber of the atomic deposition system through a special pipeline for standby. Before starting the deposition, pre-exhaust the ferrocene source steel cylinder to eliminate the air mixed in the source loading process, and ensure the stability of the ferrocene source pulse and not be oxidized and decomposed during the heating process;

[0037] 3) Send the substrate pretreated in step 1) into the...

Embodiment 3

[0041] 1) Substrate preparation: prepare the Al substrate required for the experiment at a volume ratio of concentrated H 2 SO 4 :H 2 o 2 =5:1 wash solution for 10 minutes, then the substrate was taken out from the wash solution, rinsed with a large amount of deionized water and dried with nitrogen gas for later use;

[0042] 2) Using ferrocene as the iron source and oxygen as the oxygen source to deposit ferric oxide. Put the ferrocene into the special solid-state source cylinder of the atomic layer deposition system and heat it to 165°C, and connect the oxygen to the reaction chamber of the atomic deposition system through a special pipeline for standby. Pre-exhaust the ferrocene source steel cylinder before starting the deposition to eliminate the air mixed in the source loading process, and ensure that the ferrocene source pulse is stable and will not be oxidized and decomposed during the heating process;

[0043] 3) Send the substrate pretreated in step 1) into the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com