A dust-removing concrete wall and its construction method

A technology for concrete walls and concrete walls, which is applied in the direction of walls, building components, sustainable waste treatment, etc., can solve the problems of increasing construction costs and unsatisfactory effect of dust removal equipment, and achieves increased supporting force, reduced construction dust, and adhesion. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

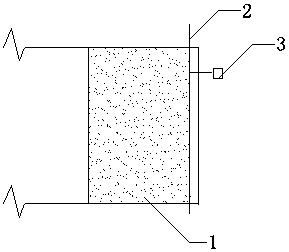

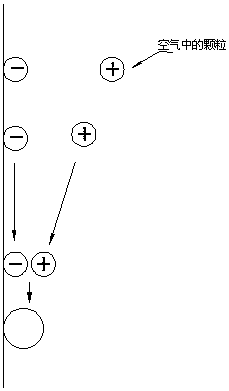

[0026] Such as figure 1 Shown, dust-removing concrete wall of the present invention is made up of concrete wall body 1, metal mesh 2 and anion generator 3; Wherein said concrete wall body 1 composition material is, according to weight ratio, traditional concrete: clay or fly ash: Glass fiber=10:2~4:0.5~1.5, the traditional concrete composition is according to the weight ratio: cement:sand:stone=1:2~2.5:2; the mesh size of the metal mesh 2 is 5~ 25mm, cold-drawn low-carbon steel wire with a monofilament strength ≥ 4500kg / cm is selected, and the diameter of the steel wire is 0.5-2mm; the connection mode between the metal meshes 2 is lap joint, and the distance between two adjacent metal meshes 2 in the horizontal and vertical directions is 50~ 100mm, the metal mesh 2 is in the concrete wall 1, and the distance from the outer surface of the concrete wall is 50-100mm. There are holes reserved on the outer surface of the wall, and the negative ion generator 3 is mounted on the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com