Multi-point gas electric control spraying system and method based on pressure-time control

A time-controlled, electronically-controlled injection technology, applied in electrical control, charging system, engine control, etc., can solve the problem of responsiveness to changes in engine performance, uneven mixing of air and gas, and reduced gas pipeline pressure, etc. problems, to achieve the effect of prolonging the duration of gas injection, promoting mixing, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

[0033] The invention provides a pressure-time control-based multi-point fuel gas electric control injection system for the purpose of effectively scavenging the gas mechanism and improving the mixing uniformity of gas and air. Compared with the premixing route and the traditional time-controlled multi-point injection route, the present invention can well-organized scavenging under different working conditions, reduces the thermal load of the engine, and improves the thermal efficiency of the engine; Mixing uniformity of gas and air.

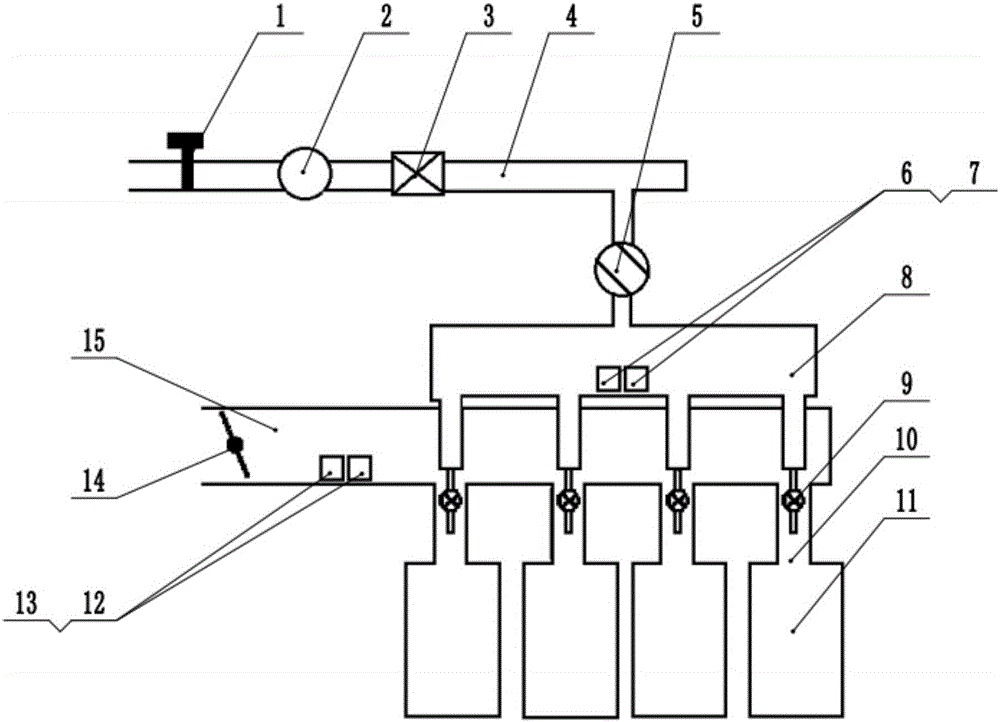

[0034] Such as figure 1As shown, the multi-point gas electronically controlled injection system based on pressure-time control mainly includes a gas supply system and an air supply system. The main components of the gas supply system include electromagnetic shut-off valve 1, filter 2, pressure reducing valve 3, gas control valve 5, gas common r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com