A remote well natural gas recovery device

A recovery device and natural gas technology, applied in the direction of gas processing applications, fixed-capacity gas storage tanks, equipment loaded into pressure vessels, etc., can solve the problems of time-consuming and laborious transportation, installation and disassembly, low transportation frequency, and no integration. , to achieve the effect of convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

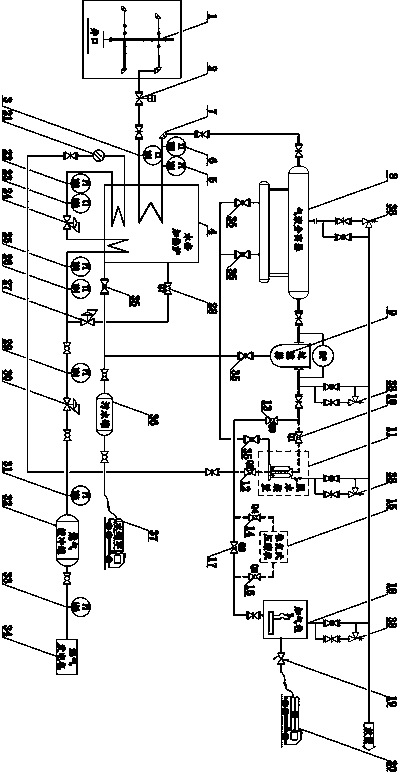

[0023] Such as figure 1 As shown, when the CNG recovered by this recovery device is directly sold as commercial gas and the wellhead pressure is lower than 20MPa or used for recovery of scattered natural gas in low temperature environments such as winter: the gas from the gas tree 1 is heated by the water jacket heating furnace 4 Enter the gas-liquid separator 8 for separation, and then filter through the first filter 9, the ball valve Q1 10 and the ball valve Q2 12 at both ends of the dehydration device 11 are opened, and the ball valve Q3 13 on the bypass pipeline is then closed, and the incoming air enters the dehydration device (11 ) to remove moisture in the natural gas, so that the water dew point of the natural gas is 5°C lower than the local minimum temperature at 20 MPa, the ball valves Q4 14 and Q5 16 at both ends of the reciprocating compressor (15) are opened, and the ball valves on the bypass pipeline Q6 17 is closed, and after dehydration, the natural gas is pres...

Embodiment 2

[0025] Such as figure 1As shown, when the CNG recovered by this recovery device is transported to the gas field gas gathering station and re-injected into the pipeline network and the wellhead pressure is lower than 20MPa: the gas from the gas tree 1 is heated by the water jacket heating furnace 4 and then enters the gas-liquid separator 8 Separated, then filtered by the first filter 9, the ball valve Q1 10 and ball valve Q2 12 at both ends of the dehydration device 11 are closed, the ball valve Q3 13 on the bypass line is opened, and the incoming air does not enter the dehydration device 11. Deep dehydration treatment, reciprocating compression The ball valve Q4 14 and ball valve Q516 at both ends of the machine 15 are opened, and the ball valve Q6 17 on the bypass pipeline is closed, and the incoming gas enters the reciprocating compressor 15 through the bypass pipeline of the dehydration device and is pressurized to 20MPa, and after being measured by the gas filling column 1...

Embodiment 3

[0027] Such as figure 1 As shown, when the CNG recovered by this recovery device is directly sold as commercial gas and the wellhead pressure is higher than 20MPa: the gas from the gas tree 1 is heated by the water jacket furnace 4 and then enters the gas-liquid separator 8 for separation, and then passes through the first The filter 9 is filtered, the ball valve Q1 10 and the ball valve Q2 12 at both ends of the dehydration device 11 are opened, and the ball valve Q3 13 on the bypass line is closed, and the incoming air enters the dehydration device 11 to remove the moisture in the natural gas, so that the water dew point of the natural gas is at At 20MPa, the temperature is 5°C lower than the local minimum temperature, the ball valve Q4 14 and ball valve Q5 16 at both ends of the reciprocating compressor (15) are closed, the ball valve Q6 17 on the bypass pipeline is opened, and the incoming gas does not pass through the reciprocating compressor 15 to increase directly throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com