ZnS nanobelt/CdS nanorod heterojunction synthetic method

A synthesis method and nano-column technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effect of simple experimental scheme, low cost, and strong experimental repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

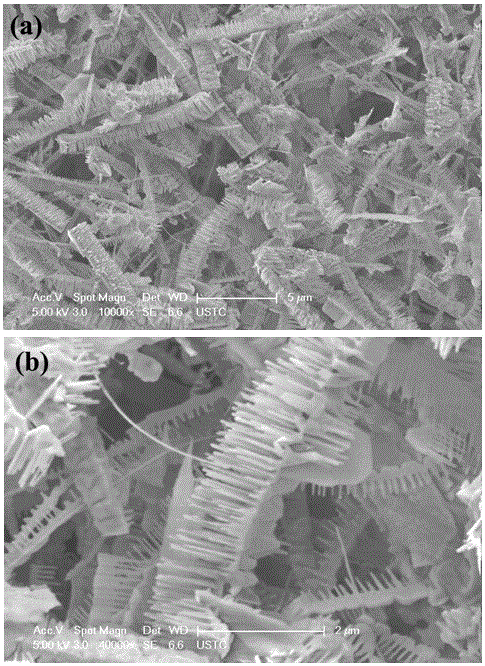

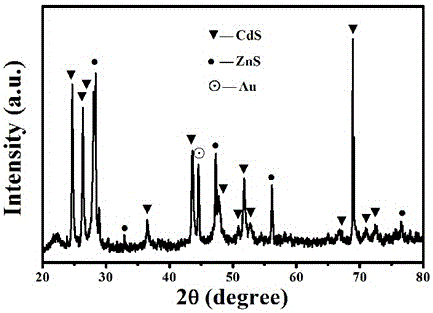

[0015] The first step: use an ion sputtering device to plate an Au film with a thickness of about 100nm on a silicon wafer (100 crystal orientation, 0.9cm*0.9cm), and use this coated silicon wafer as a catalyst. Step 2: Push the ceramic boat containing 0.7g ZnS powder into the quartz tube to the position of the thermocouple of the tube furnace, and then push the above-mentioned substrate into the quartz tube to a place 15cm away from the lower tuyere of the ceramic boat. Afterwards, argon gas was introduced for 30 minutes to discharge the oxygen present in the quartz tube. Under the protection of argon, the reaction temperature was raised from room temperature to 900°C and reacted at this temperature for 2 hours. After the whole device was cooled to room temperature, it could be observed that A certain amount of white sample was deposited on the substrate. Step 3: Place the ceramic boat containing 0.1g of CdS powder at the position of the thermocouple, and place the white samp...

Embodiment 2

[0019] The first step: use an ion sputtering device to plate an Au film with a thickness of about 120 nm on a silicon wafer (100 crystal orientation, 0.9 cm*0.9 cm), and use this coated silicon wafer as a catalyst. Step 2: Push the ceramic boat containing 0.75g of ZnS powder into the quartz tube to the position of the tube furnace thermocouple, and then push the above-mentioned substrate into the quartz tube to a distance of 16 cm from the lower tuyere of the ceramic boat. Afterwards, argon was introduced for 30 minutes to discharge the oxygen present in the quartz tube. Under the protection of argon, the reaction temperature was raised from room temperature to 920°C and reacted at this temperature for 2.5 hours. After the whole device was cooled to room temperature, it could be observed A certain amount of white sample was deposited on the substrate. Step 3: Place the ceramic boat containing 0.1g of CdS powder at the position of the thermocouple, and place the white sample pr...

Embodiment 3

[0021] The first step: use an ion sputtering device to plate an Au film with a thickness of about 80nm on a silicon wafer (100 crystal orientation, 0.9 cm*0.9 cm), and use this coated silicon wafer as a catalyst. The second step: push the ceramic boat containing 0.65g ZnS powder into the quartz tube to the position of the thermocouple of the tube furnace, and then push the above-mentioned substrate into the quartz tube to a distance of 17cm from the lower tuyere of the ceramic boat. Afterwards, argon gas was introduced for 30 minutes to discharge the oxygen present in the quartz tube. Under the protection of argon, the reaction temperature was raised from room temperature to 880 ° C and reacted at this temperature for 1.5 hours. After the whole device was cooled to room temperature, it could be observed that A certain amount of white sample was deposited on the substrate. Step 3: Place the ceramic boat containing 0.1g of CdS powder at the position of the thermocouple, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com