Filament for artificial hair and artificial hair product

A technology of artificial hair and filaments, applied in filament/thread molding, wigs, applications, etc., can solve the problems of cracked and broken filaments, unnatural luster, and difficulty in showing a three-dimensional effect, so as to achieve difficult to crack, Excellent glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

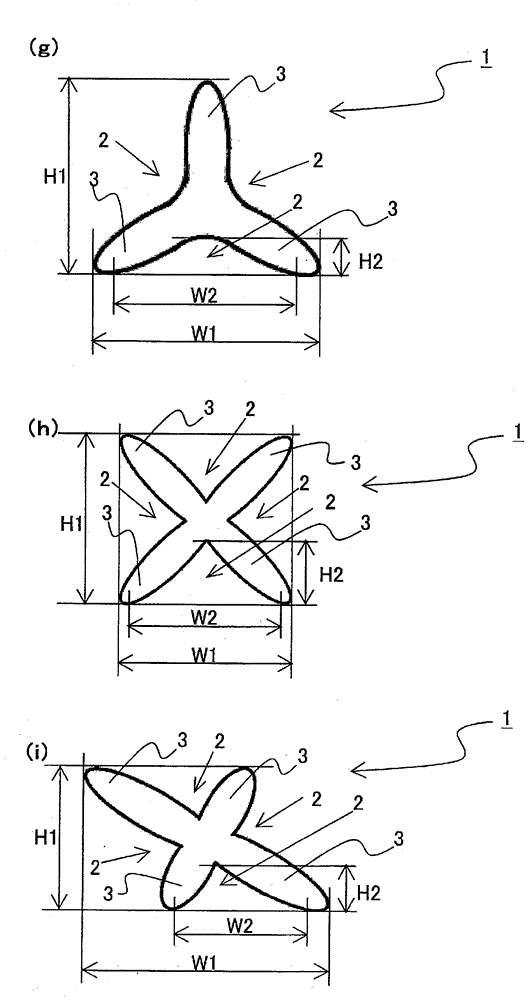

[0089] Polyterephthalate containing 2.5% by mass of aggregated silica particles (average particle size: 2.43 μm) and an intrinsic viscosity (measured at 25°C in a 1:1 mixed solvent of phenol and tetrachloroethane) of 0.97 The ethylene glycol formate chips were dried in vacuo at 165°C for 9 hours. The chips were supplied to an extrusion-type spinning machine at 285° C., and the heated and melted resin composition was obtained from figure 1 (a) Extruded through a 3-lobe nozzle with the cross-sectional shape of the filament, immediately cooled in 30°C water, then stretched to 4.1 times in warm water at 55°C and dry heat at 100°C, and then relaxed in a dry heat atmosphere heat treatment.

[0090] Next, as an alkali treatment, the coiled monofilament was immersed in a sodium hydroxide solution, the surface of the wool material was dissolved, washed with water, and dried to obtain a straight polyester monofilament.

[0091] The polyester monofilament was dyed black by a convention...

Embodiment 2

[0094] Using polyethylene terephthalate chips containing 1.5% by mass of colloidal silica (Syrisia 730 manufactured by Fuji Silisia Chemical Co., Ltd.) and having an intrinsic viscosity of 1.10, the extrusion nozzle was changed to correspond to figure 1 A straight monofilament for artificial hair was obtained in the same manner as in Example 1 except for the three-leaf nozzle having the filament cross-sectional shape in (c).

[0095] Table 1 shows the properties of the obtained filament for artificial hair.

Embodiment 3、4

[0096] [Examples 3 and 4, Comparative Examples 1 to 3]

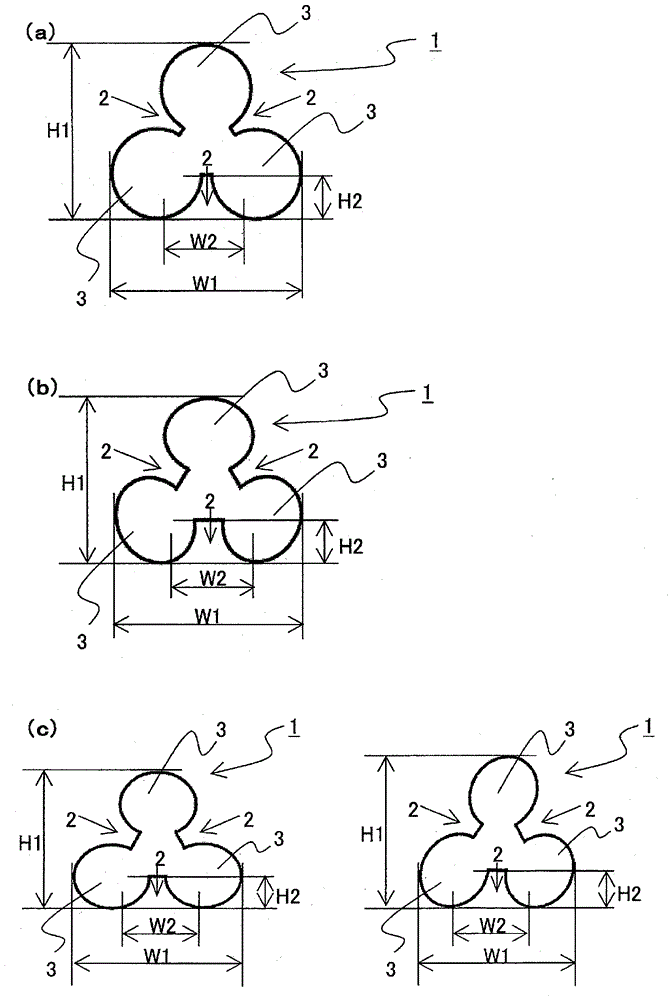

[0097] Straight monofilaments for artificial hair were obtained in the same manner as in Example 2 except that the extrusion nozzle was changed to one corresponding to each shape shown in Table 1.

[0098] Table 1 shows the properties of the obtained filament for artificial hair.

[0099] [Table 1]

[0100]

[0101] From Table 1, it was confirmed that the filaments for artificial hair according to the examples of the present invention are excellent in volume and luster, and are less prone to tearing and breaking.

[0102] On the other hand, the filaments for artificial hair (Comparative Examples 1 to 3) having a cross-sectional shape that does not satisfy the conditions of the present invention not only have an unnatural sense of volume and luster, but are also prone to tearing and breaking, and are not suitable for use as artificial hair. Use filament.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com