Vacuum freeze-dried fruit-vegetable powder yoghurt and preparation method thereof

A vacuum freeze-drying, fruit and vegetable yogurt technology, applied in the direction of milk preparations, dairy products, milk preservation, etc., can solve the problems of single product nutrition, short shelf life of yogurt, etc., and achieve rich nutritional structure, bright color, convenient eating and carrying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

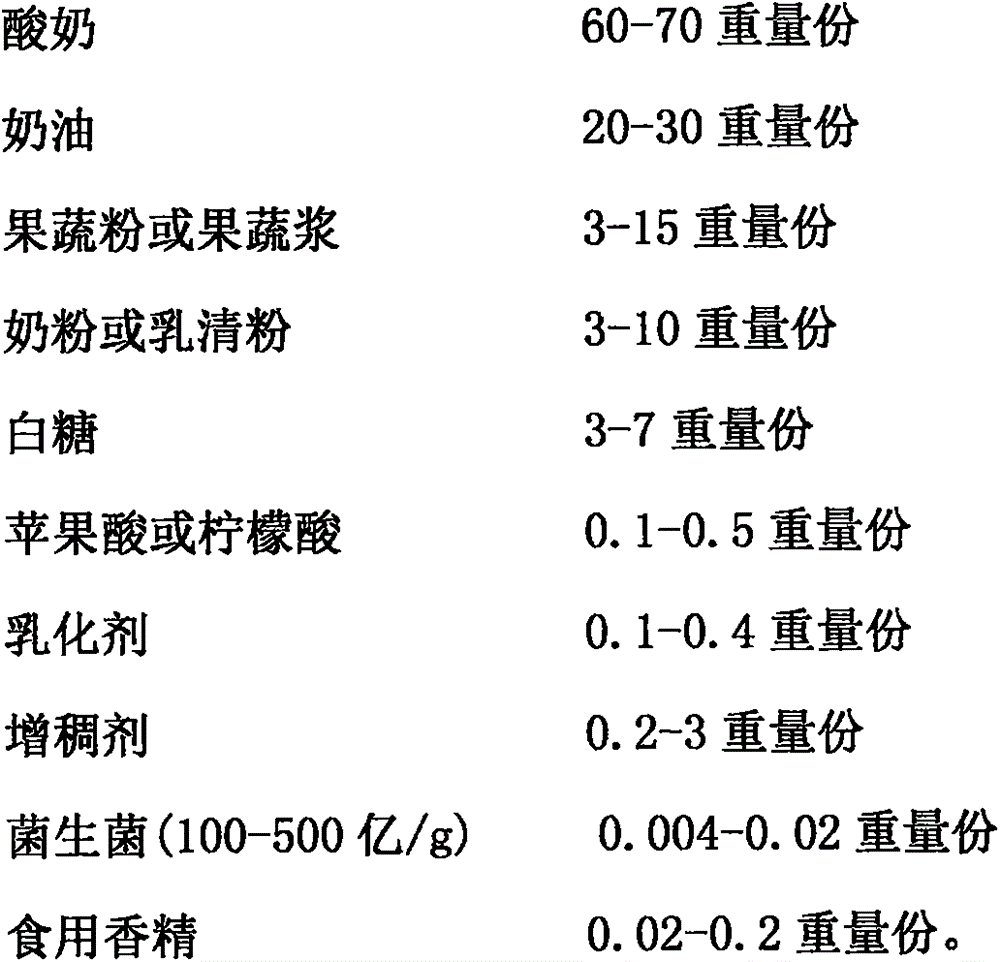

[0033] (1) Take each component by the following parts by weight:

[0034]

[0035] (2) Fully melt the vegetable cream to a fluid state, and use a whisk to fully stir until foaming, and the time is controlled within 20-25 minutes;

[0036] (3) Put the yogurt in a sandwich pot or a water-soluble pot, add an emulsifier in proportion, and add 2-3 times the weight of the yogurt powder to dissolve in water for dilution, keep stirring, and control the temperature to rise to 50 degrees within 30 minutes to obtain yogurt liquid;

[0037] (4) Add each component that has been weighed into (3) processed yogurt liquid, and stir to obtain a mixture;

[0038] (5) Carry out homogenization with high-speed stirrer with mixed material, obtain homogeneous material;

[0039] (6) molding the homogeneous material, using a mold or an injection molding machine to form a molding material;

[0040] (7) Slowly freeze the molding material in an environment of -8 to -12 degrees or directly place the ...

Embodiment 2

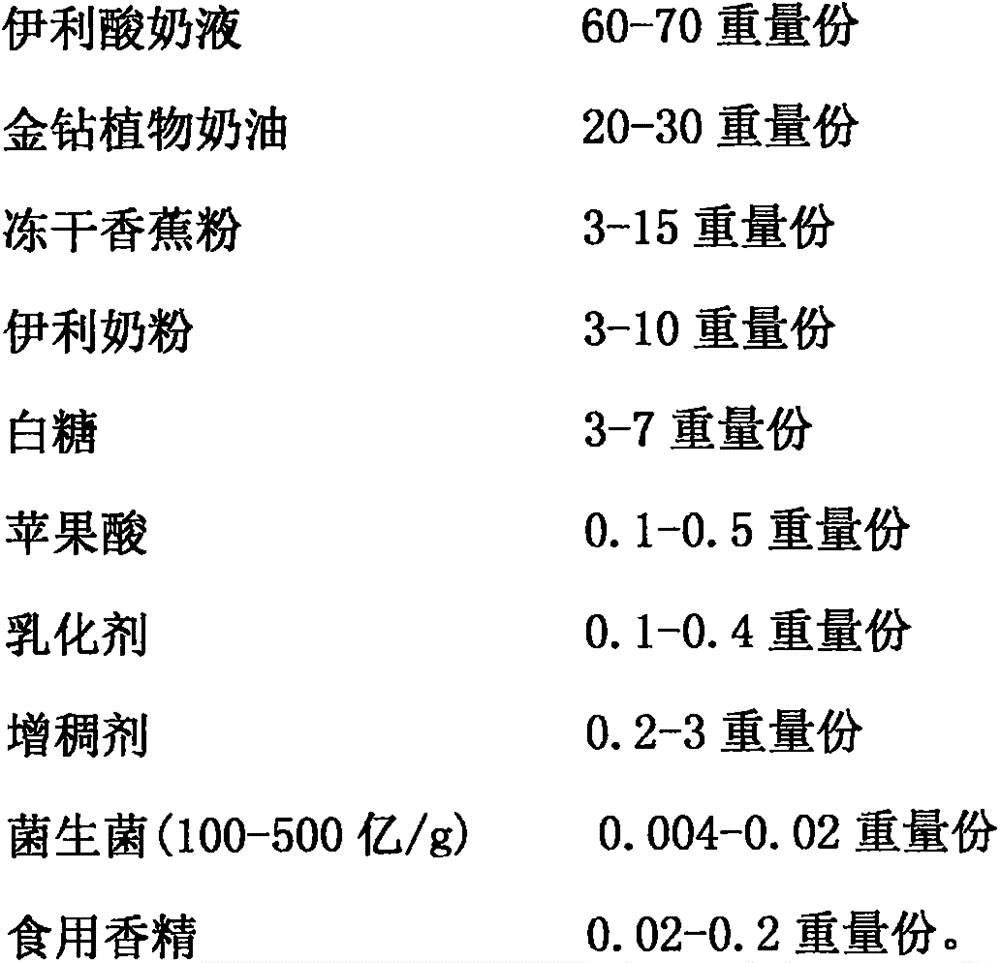

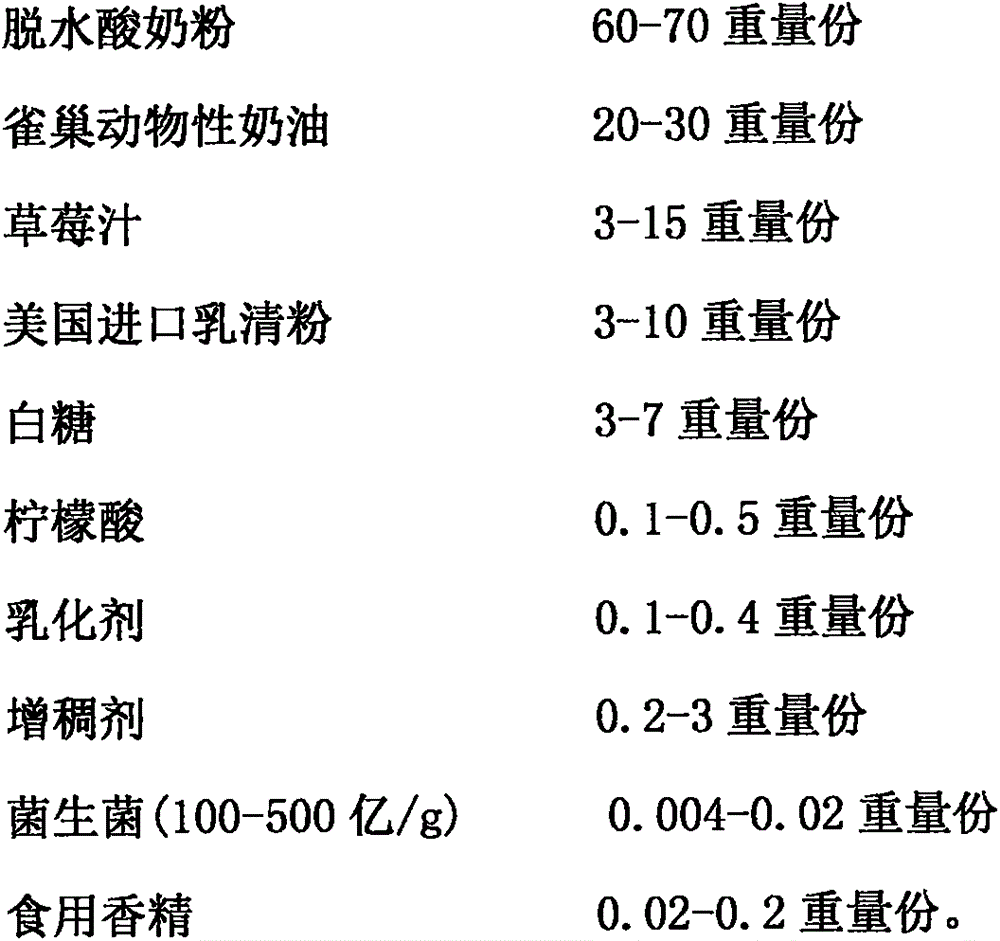

[0047] (1) Take each component by the following parts by weight:

[0048]

[0049] (2) Fully heat up the animal cream and melt it into a fluid state, use a whisk to stir and beat until foaming, and control the whipping time to 20-25 minutes;

[0050] (3) Dissolve yogurt powder in 50-degree warm water with twice the weight of yogurt powder, place it in a sandwich pot or water-soluble pot for constant temperature at 50 degrees, and add 2-3 times the weight of yogurt powder in water to dissolve and dilute, proportionally Add an emulsifier and keep stirring for 30 minutes to obtain a yogurt liquid;

[0051] (4) Add each component that has been weighed into (3) processed yogurt liquid, and stir to obtain a mixture;

[0052] (5) Carry out homogenization with high-speed stirrer with mixed material, obtain homogeneous material;

[0053] (6) molding the homogeneous material, using a mold or an injection molding machine to form a molding material;

[0054] (7) slowly freezing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com