Concentrated feed for layers

A technology of concentrated feed and concentrated feed, which is applied in the field of animal husbandry, can solve the problems of affecting the economic income of chicken farms, poor eggshell quality, and low profits of chicken farms, so as to improve the utilization rate of intestinal digestion and absorption, improve the quality of eggs, The effect of improving the profit of the chicken farm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

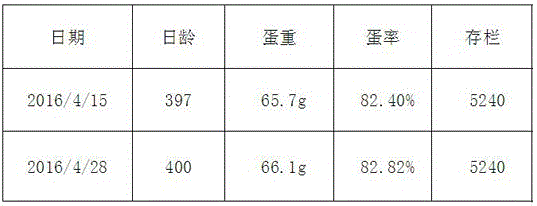

Image

Examples

Embodiment 1

[0021] A concentrated feed for laying hens is composed of the following components by weight: 2000 parts of 46% peeled soybean meal, 2000 parts of 45% cotton meal, 800 parts of stone powder, 500 parts of sprayed corn husks, 300 parts of calcium hydrogen phosphate, 200 parts of layer vitamins, 400 parts of layer trace elements, 300 parts of glutamic acid residue, 50 parts of table salt, 50 parts of methionine, 50 parts of soybean oil, 50 parts of choline chloride, and 5 parts of lysine hydrochloride.

[0022] The concentrated feed accounts for 10.1% of the full price feed.

[0023] During preparation, the above-mentioned components in various parts are mixed, pulverized into powder by conventional methods, and that is enough.

Embodiment 2

[0025] A concentrated feed for laying hens is composed of the following components by weight: 4000 parts of 46% peeled soybean meal, 5000 parts of 45% cotton meal, 2000 parts of stone powder, 1500 parts of sprayed corn husks, 1000 parts of calcium hydrogen phosphate, 300 parts of layer vitamins, 600 parts of layer trace elements, 500 parts of glutamic acid residue, 260 parts of table salt, 150 parts of methionine, 100 parts of soybean oil, 80 parts of choline chloride, and 10 parts of lysine hydrochloride.

[0026] The concentrated feed accounts for 10.1% of the full price feed.

[0027] During preparation, the above-mentioned components in various parts are mixed, pulverized into powder by conventional methods, and that is enough.

Embodiment 3

[0029] A concentrated feed for laying hens is composed of the following components by weight: 3000 parts of 46% peeled soybean meal, 3000 parts of 45% cotton meal, 1000 parts of stone powder, 1000 parts of sprayed corn husks, 800 parts of calcium hydrogen phosphate, 250 parts of layer vitamins, 500 parts of layer trace elements, 400 parts of glutamic acid residue, 120 parts of table salt, 90 parts of methionine, 70 parts of soybean oil, 60 parts of choline chloride, and 8 parts of lysine hydrochloride.

[0030] The concentrated feed accounts for 10.1% of the full price feed.

[0031] During preparation, the above-mentioned components in various parts are mixed, pulverized into powder by conventional methods, and that is enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com