A high-throughput preparation method for prolonging the service life of multi-acid-based Fischer-Tropsch composite catalysts

A technology of composite catalyst and service life, which is applied in the direction of catalyst activation/preparation, preparation of liquid hydrocarbon mixture, catalyst protection, etc. It can solve the problems of low added value and achieve the effect of moderate pore size, simple preparation method and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The high-throughput preparation method of the present invention for extending the service life of the multi-acid-based Fischer-Tropsch composite catalyst includes the following steps:

[0028] In step 1, the polyacid with a mass fraction of 1-90% and a Fischer-Tropsch synthesis catalyst with a mass fraction of 10-99% are hydrothermally combined to form a polyacid-based Fischer-Tropsch synthesis catalyst. The polyacid catalyst is any one or a combination of any of Keggin type polyacid salt, Dawson type polyacid salt and Lindqvist type polyacid salt. The general formula of the Keggin type polyacid salt is: A m H n [XM 12 O 40 ] (A = Li, Na, K, Cs, Mg, Ga, Al, Ce; X = Si, Ge, P, As, B; M = W, Mo; The general formula of Dawson type polyacid salt is : A m H n [X 2 M 18 O 62 ] (A = Li, Na, K, Cs; X = P, As; M = W, Mo; m = 0-6; n = 0-6); The general formula of the Lindqvist type polyacid salt is: A m H n [X x M y O 19 ] (A = Li, Na, K, Cs; X&M = V, Nb, W, Mo, Ta; x + y = 6; m = 0...

Embodiment 1

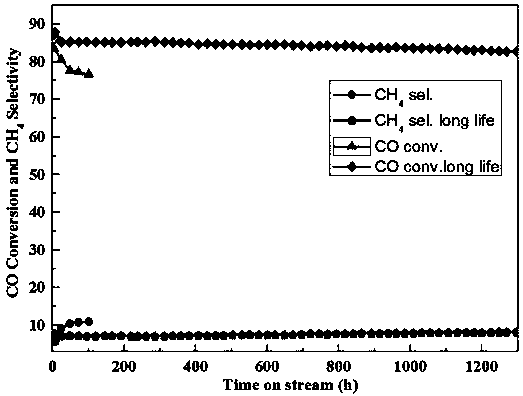

[0042] In this embodiment, see figure 2 As shown in Table 1, a high-throughput preparation method for prolonging the service life of a polyacid-based Fischer-Tropsch synthesis catalyst includes the following steps:

[0043] Add 5 grams of polyacid catalyst H 3 PW 12 O 40 Pour into a beaker containing 10 grams of deionized water and stir magnetically for 30 minutes until completely dissolved. Put 5 grams of Fischer-Tropsch synthesis catalyst 10Co / Al 2 O 3 Put it into a beaker and stir mechanically until the solution containing the polyacid is impregnated into the pores of the Fischer-Tropsch synthesis catalyst carrier. Keep immersing for 6 hours, stirring every half an hour during this period to ensure full immersion. Then the catalyst in the beaker was transferred to a 25ml polytetrafluoroethylene lined autoclave, heated at 150°C for 72 hours, cooled naturally, cooled and dried, and calcined at 200°C for 4 hours to obtain a polyacid-based Fischer-Tropsch composite catalyst. Th...

Embodiment 2

[0046] Add 4 grams of polyacid catalyst H 4 SiW 12 O 40 Pour into a beaker containing 10 grams of deionized water, heat and stir for 5 minutes until completely dissolved. Add 6 grams of Fischer-Tropsch synthesis catalyst 5Ru / Al 2 O 3 Put it in a beaker and stir until the solution containing polyacid is immersed in the pores of the Fischer-Tropsch synthesis catalyst carrier. Keep immersing for 10 hours, stirring every hour during this period to ensure full immersion. Then the catalyst in the beaker was transferred to a 25ml polytetrafluoroethylene liner autoclave, heated at 180°C for 96 hours, cooled naturally, cooled and dried, and calcined at 300°C for 2 hours to obtain a composite catalyst. A solution of TEOS and 1M dilute hydrochloric acid was prepared at a molar ratio of 1:3, and the solution was put into a high flux hydrothermal reactor at a ratio of 1:2 with a polyacid-based Fischer-Tropsch synthesis catalyst, and heated to 150 under autogenous pressure. o C, keep for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com