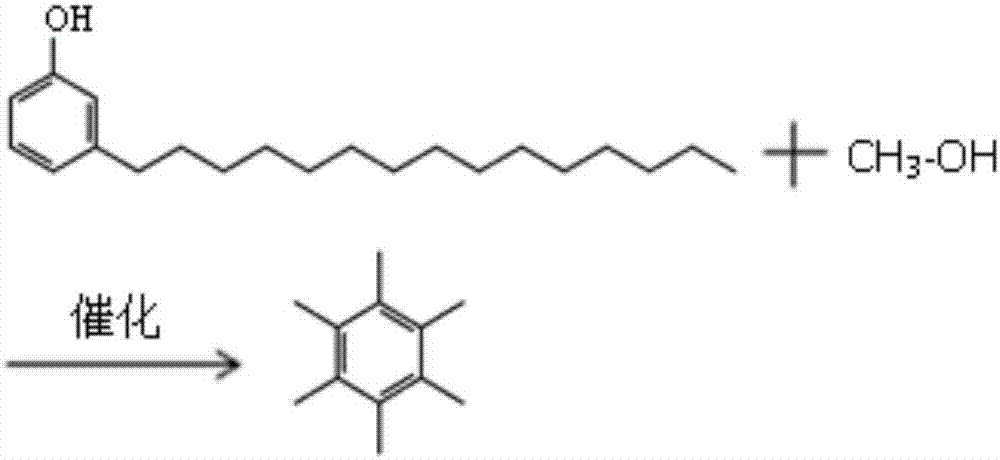

Method for preparing hexamethylbenzene by using cardanol and methanol as raw materials

A technology for hexamethylbenzene and cardanol, which is applied in the field of preparing hexamethylbenzene, can solve the problems of high requirements on reaction conditions, waste of raw materials and high energy consumption, and achieves the effects of low price, mild process conditions and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of hexamethylbenzene from cardanol and methanol:

[0042] (1) Add 5g of 20-40 mesh granular solid catalyst in the reaction tube, place it in a tubular heating furnace, heat it to 300°C, feed nitrogen, and the pressure is normal pressure;

[0043] (2) Cardanol and methanol are mixed at a volume ratio of 1:1 and then pumped into the nitrogen flow through the material, and the mixed gas-liquid material enters the fixed-bed catalytic reactor, and reacts at a temperature of 300 ° C to generate hexamethylbenzene;

[0044] (3) The above-mentioned crude product hexamethylbenzene is recrystallized, and the solvent used for recrystallization purification is dichloromethane and benzene to obtain the finished product of hexamethylbenzene, and its target selectivity (mass ratio of hexamethylbenzene in the crystallization product) ) was 27.9%; product (crystal product) yield was 82.3%.

Embodiment 2

[0046] Preparation of hexamethylbenzene from cardanol and methanol:

[0047] (1) Add 5g of 20-40 mesh granular solid catalyst into the reaction tube, place it in a tubular heating furnace, heat it to 350°C, feed nitrogen, and the pressure is normal pressure;

[0048] (2) Cardanol and methanol are mixed at a volume ratio of 1:1 and then pumped into the nitrogen stream through the material, and the mixed gas-liquid material enters the fixed-bed catalytic reactor, and reacts at a temperature of 350 ° C to generate hexamethylbenzene;

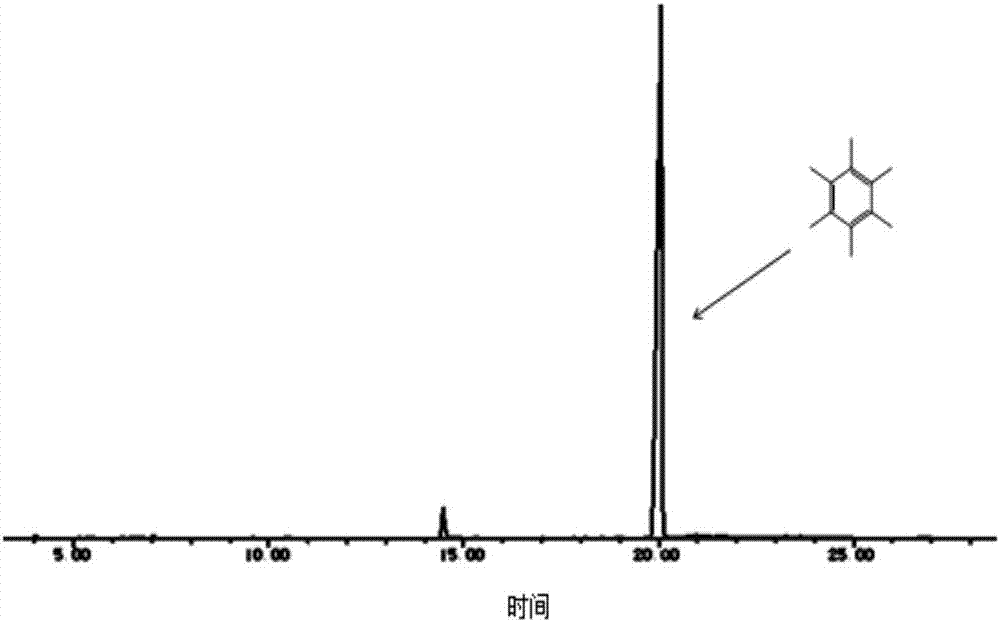

[0049] (3) Recrystallize the above-mentioned crude product hexamethylbenzene, and the solvents used for recrystallization and purification are dichloromethane and benzene to obtain finished hexamethylbenzene with a target selectivity of 96.1% and a product yield of 80.7%.

Embodiment 3

[0051] Preparation of hexamethylbenzene from cardanol and methanol:

[0052] (1) Add 5g of 20-40 mesh granular solid catalyst into the reaction tube, place it in a tubular heating furnace, heat it to 400°C, feed nitrogen, and the pressure is normal pressure;

[0053] (2) Cardanol and methanol are mixed at a volume ratio of 1:1 and then pumped into the nitrogen stream through the material, and the mixed gas-liquid material enters the fixed-bed catalytic reactor, and reacts at a temperature of 400 ° C to generate hexamethylbenzene;

[0054] (3) Recrystallize the crude product of hexamethylbenzene to obtain the finished product of hexamethylbenzene. The solvents used for recrystallization and purification are dichloromethane and benzene, and the target selectivity is 98.9%; the product yield is 73.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com