Interlaminar-toughened laminated composite material and preparation method thereof

A composite material and toughening technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problem of unsuitable large-scale batch production, local small area is not very good, and in-plane toughening "resolution" The problems such as low efficiency can be solved, and the preparation method process can be clear, the effect of improving the I-type interlaminar fracture toughness, and improving the toughening efficiency and resolution can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] 1) Hydroentangled interlayer toughening method of laminated composite materials:

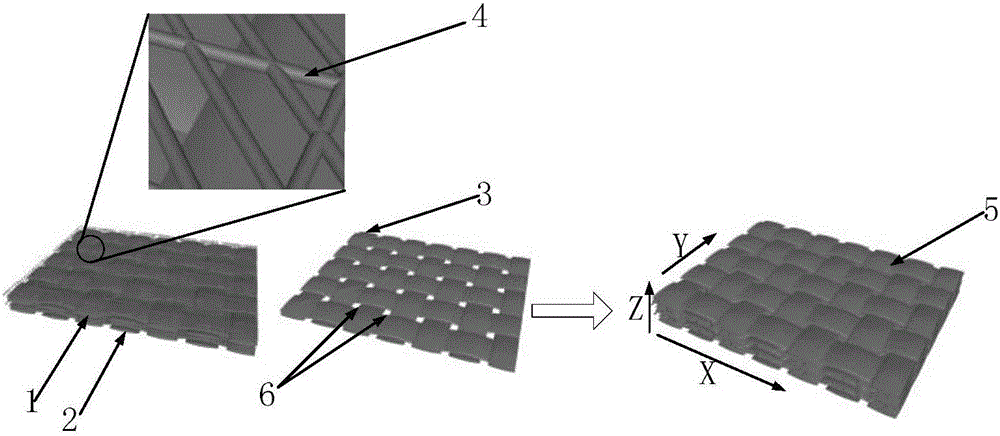

[0032] For the microstructure of laminated carbon fiber preforms, such as figure 1 As shown, it can be seen that the stacked carbon fiber preform has a channel in the thickness direction consisting of the middle gap 6 where the main fibers (that is, the fibers of the woven carbon cloth) interweave in each layer in the XY direction, which is a typical interconnected tubular porous media structure. .

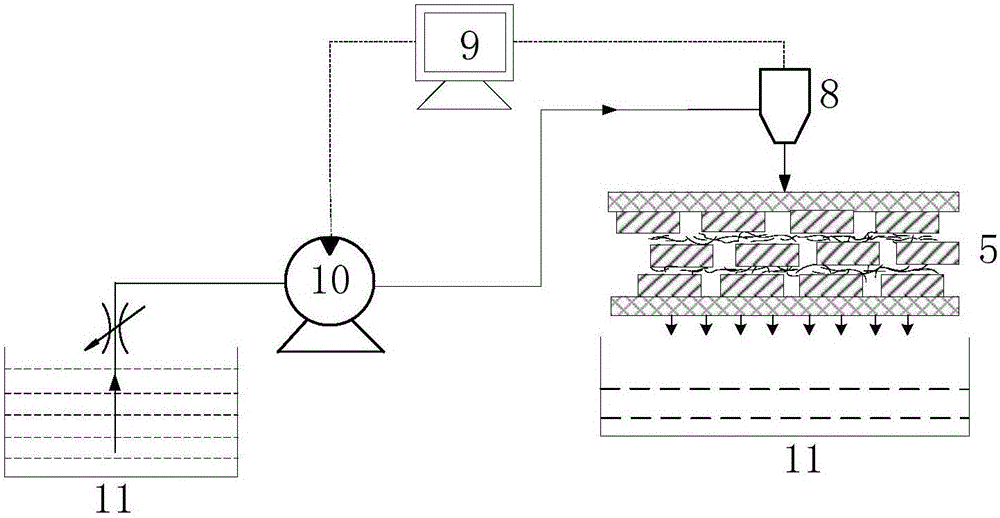

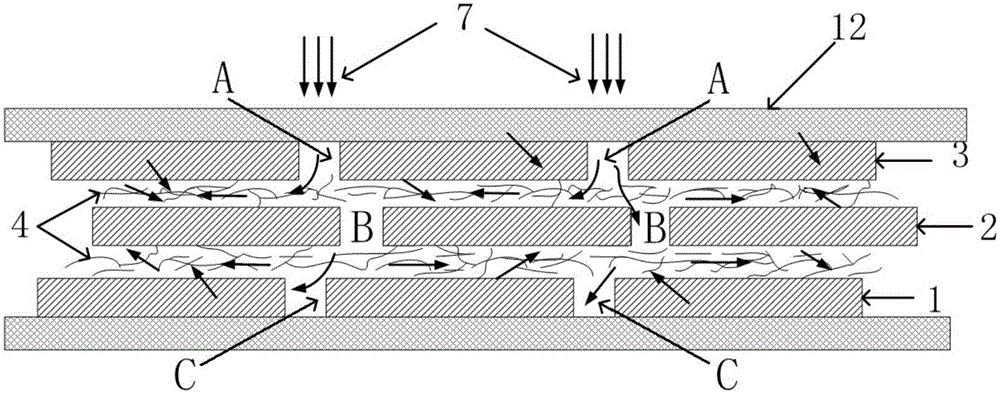

[0033] see figure 2 , when the high-pressure fine water flow 7 shoots towards and passes through the laminated carbon fiber prefabricated body, the fluid collides with the main fiber and the metal support net 12, agitates, multi-directional scattering occurs, and various jet distributions are formed in the interconnected tubular porous media structure, Such as im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com