Method for preparing smooth graphene film by pulling method

A graphene film and pulling method, applied in the field of nanomaterial preparation, can solve the problems of many wrinkles and large roughness of the graphene film, and achieve the effects of easy functional modification, flat graphene film and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Weigh 0.02 gram of graphene oxide and dissolve it in 20 milliliters of ultrapure water, and ultrasonicate for 2 hours to obtain a uniform 1.0 milligram per milliliter graphene oxide aqueous solution.

[0037] (2) Measure 21 ml of 98% concentrated sulfuric acid and 9 ml of 30% hydrogen peroxide to prepare a piranha solution, put the glass slide into it and etch it for 2 hours, then take it out and wash it with ethanol and ultrapure water in turn.

[0038] (3) Measure 29 milliliters of toluene and 1 milliliter of 3-aminopropyltriethoxysilane as a solution, put the glass slide etched by the piranha solution into it for 30 minutes, take it out and wash it with toluene in turn , ethanol and ultrapure water.

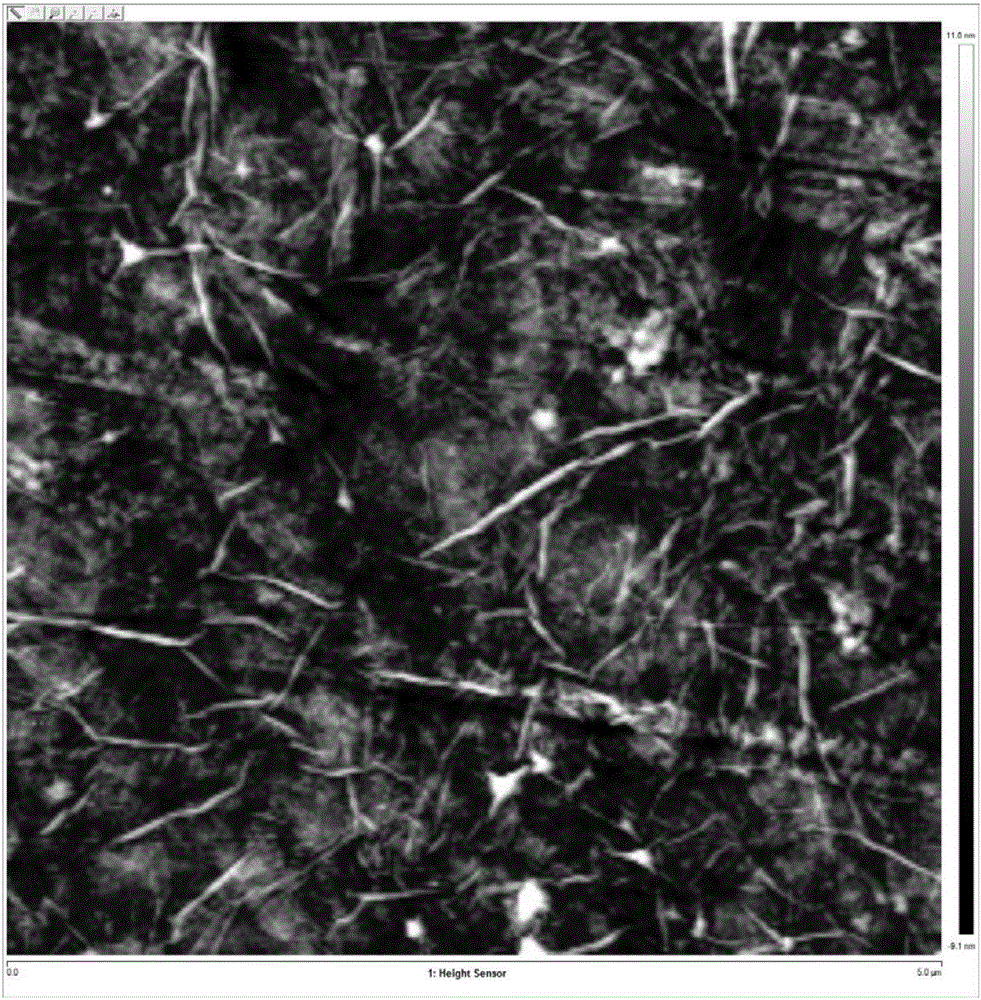

[0039] (4) Using the pretreated glass slide as the substrate, in the prepared graphene oxide solution, prepare a graphene oxide film by pulling and coating, and the pulling speed is controlled to be 500 nanometers per second.

[0040] (5) Put the glass substrate co...

Embodiment 2

[0044] (1) Weigh 0.03 gram of graphene oxide and dissolve it in 20 milliliters of ultrapure water, and ultrasonicate for 3 hours to obtain a uniform graphene oxide aqueous solution of 1.5 milligrams per milliliter.

[0045] (2) Measure 21 ml of 98% concentrated sulfuric acid and 9 ml of 30% hydrogen peroxide to prepare a piranha solution, put the glass slide into it and etch it for 2 hours, then take it out and wash it with ethanol and ultrapure water in turn.

[0046] (3) Measure 29 milliliters of toluene and 1 milliliter of 3-aminopropyltriethoxysilane as a solution, put the glass slide etched by the piranha solution into it for 30 minutes, take it out and wash it with toluene in turn , ethanol and ultrapure water.

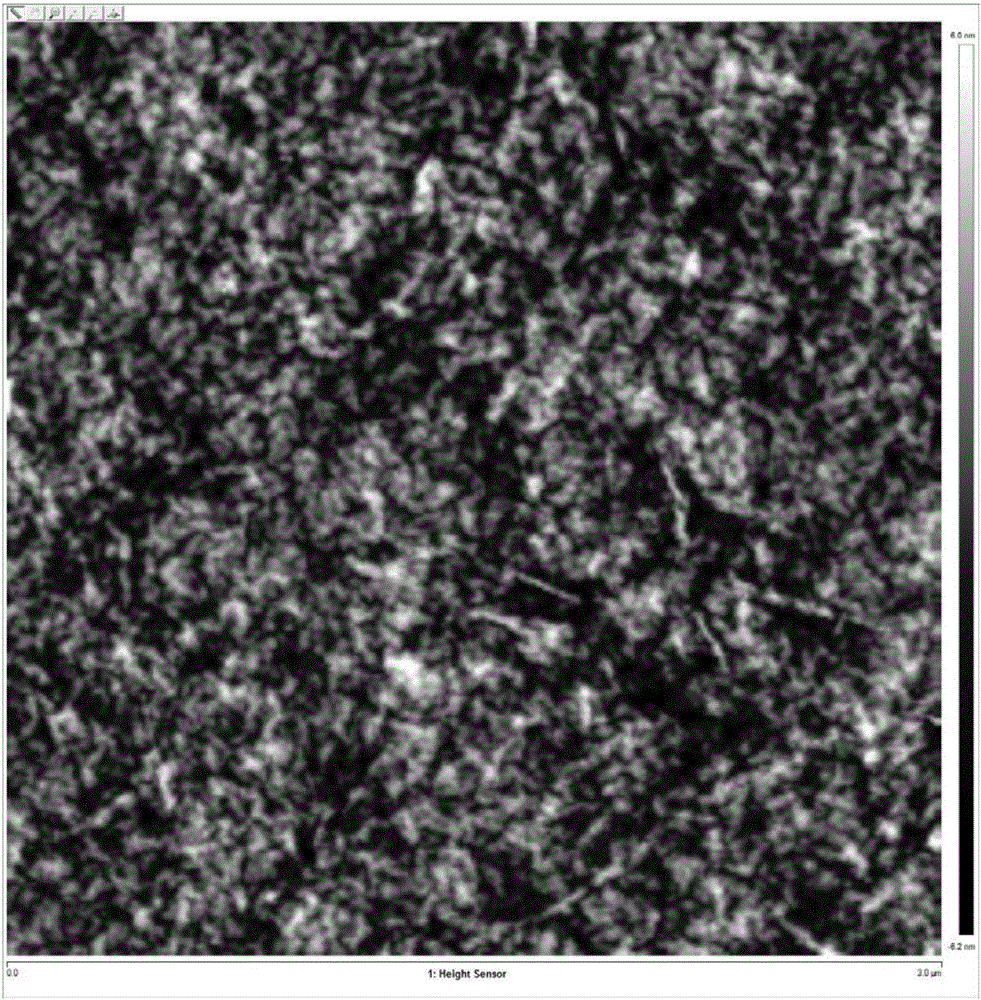

[0047] (4) Using the pretreated glass slide as the substrate, in the prepared graphene oxide solution, a graphene oxide film was prepared by pulling and coating, and the pulling speed was controlled to be 250 nanometers per second.

[0048] (5) Put the glass su...

Embodiment 3

[0051] (1) Weigh 0.01 gram of graphene oxide and dissolve it in 20 milliliters of ultrapure water, and ultrasonicate for 1 hour to obtain a uniform 0.5 milligram per milliliter graphene oxide aqueous solution.

[0052] (2) Measure 21 ml of 98% concentrated sulfuric acid and 9 ml of 30% hydrogen peroxide to prepare a piranha solution, put the glass slide into it and etch it for 2 hours, then take it out and wash it with ethanol and ultrapure water in turn.

[0053] (3) Measure 29 milliliters of toluene and 1 milliliter of 3-aminopropyltriethoxysilane as a solution, put the glass slide etched by the piranha solution into it for 30 minutes, take it out and wash it with toluene in turn , ethanol and ultrapure water.

[0054] (4) Using the pretreated glass slide as the substrate, in the prepared graphene oxide solution, the graphene oxide film was prepared by pulling and coating, and the pulling speed was controlled to be 700 nanometers per second.

[0055] (5) Put the glass subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com