Simple and efficient production method for phenyl chloroformate

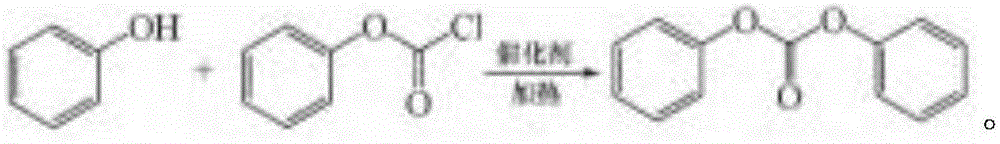

A technology for the production of phenyl chloroformate, which is applied in the preparation of phosgene or haloformate, organic chemistry, etc., can solve the problems of low production efficiency, achieve easy control, shorten the reaction time, and reduce the by-product dicarbonate The effect of phenyl esters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Firstly, phenol is processed into a molten state for subsequent use;

[0023] Secondly, the above-mentioned phenol is transferred to the phenol spray tank, the catalyst is transferred to the catalyst spray tank, the phenol spray tank is arranged above the reaction tank, the catalyst spray tank is arranged on one side of the reaction tank, and the catalyst spray tank and the phenol spray tank The liquid outlets at the bottom of the tank are all connected to the liquid outlet pipe, and the liquid outlet end of the liquid outlet pipe is provided with a nozzle, and the nozzle of the catalyst spray tank is arranged in the middle of the inner wall of the reaction tank, and the nozzle of the catalyst spray tank faces the middle of the reaction tank. In the upper part, the nozzle of the phenol spray tank is arranged on the top in the reaction tank, the middle part of the reaction tank is provided with a phosgene air inlet, and one side of the reaction tank is connected to a circ...

Embodiment 2

[0033] Firstly, phenol is processed into a molten state for subsequent use;

[0034] Secondly, the above-mentioned phenol is transferred to the phenol spray tank, the catalyst is transferred to the catalyst spray tank, the phenol spray tank is arranged above the reaction tank, the catalyst spray tank is arranged on one side of the reaction tank, and the catalyst spray tank and the phenol spray tank The liquid outlets at the bottom of the tank are all connected to the liquid outlet pipe, and the liquid outlet end of the liquid outlet pipe is provided with a nozzle, and the nozzle of the catalyst spray tank is arranged in the middle of the inner wall of the reaction tank, and the nozzle of the catalyst spray tank faces the middle of the reaction tank. In the upper part, the nozzle of the phenol spray tank is arranged on the top in the reaction tank, the middle part of the reaction tank is provided with a phosgene air inlet, and one side of the reaction tank is connected to a circ...

Embodiment 3

[0044] Firstly, phenol is processed into a molten state for subsequent use;

[0045]Secondly, the above-mentioned phenol is transferred to the phenol spray tank, the catalyst is transferred to the catalyst spray tank, the phenol spray tank is arranged above the reaction tank, the catalyst spray tank is arranged on one side of the reaction tank, and the catalyst spray tank and the phenol spray tank The liquid outlets at the bottom of the tank are all connected to the liquid outlet pipe, and the liquid outlet end of the liquid outlet pipe is provided with a nozzle, and the nozzle of the catalyst spray tank is arranged in the middle of the inner wall of the reaction tank, and the nozzle of the catalyst spray tank faces the middle of the reaction tank. In the upper part, the nozzle of the phenol spray tank is arranged on the top in the reaction tank, the middle part of the reaction tank is provided with a phosgene air inlet, and one side of the reaction tank is connected to a circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com