Intelligent heat management system for engine and control method

A technology of intelligent thermal management and control method, applied in engine components, machine/engine, engine cooling, etc., can solve problems such as prolonged working hours, high failure rate of fans and control modules, and untimely cooling of fans. The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in detail below with reference to accompanying drawing and embodiment:

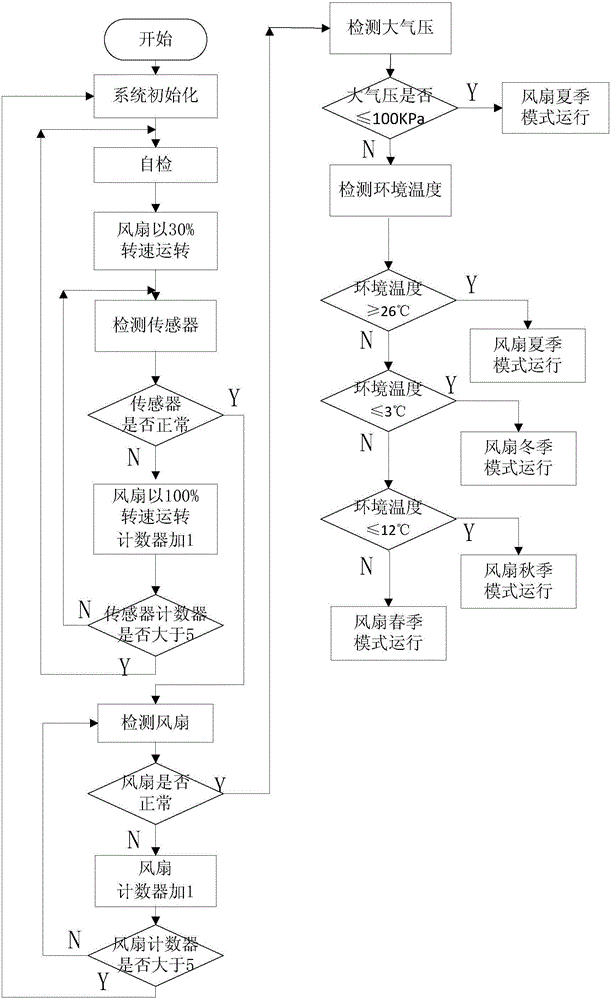

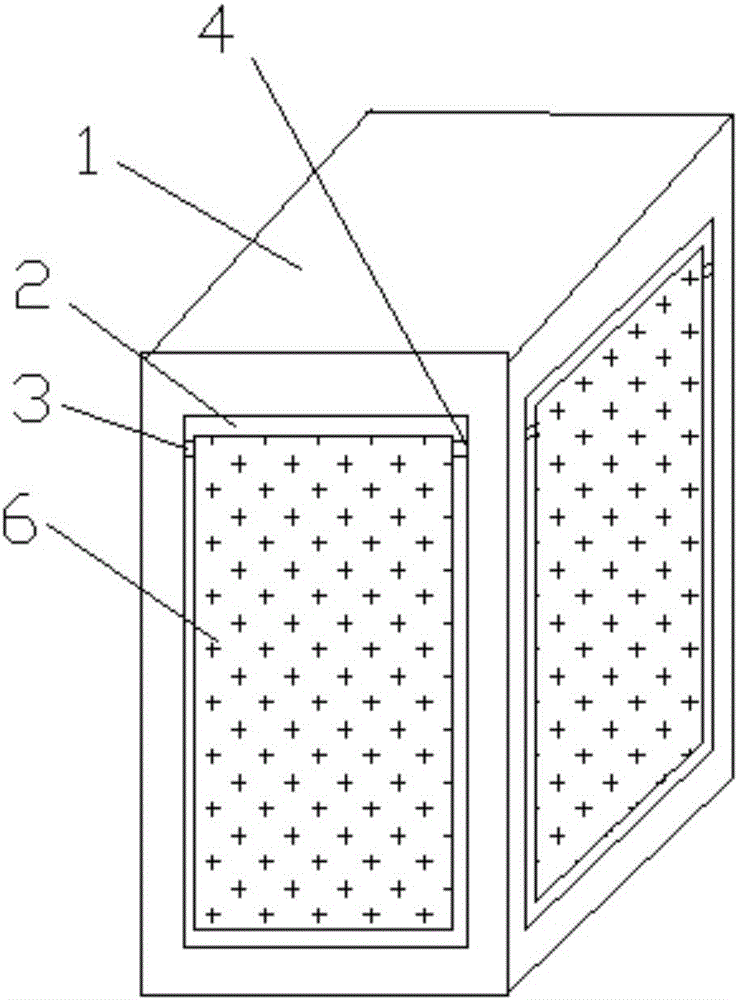

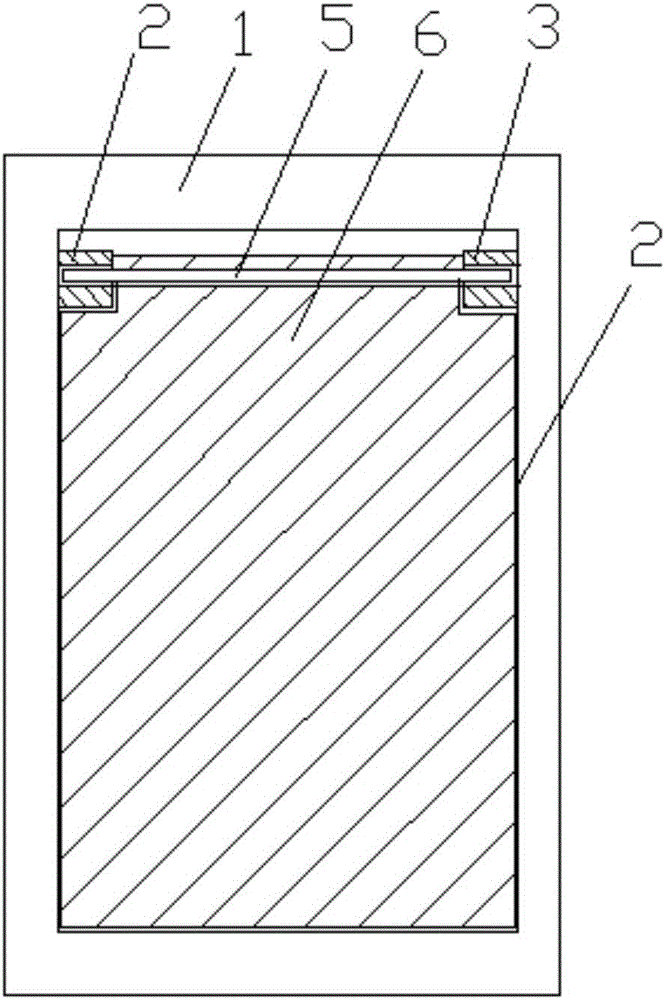

[0058] attached Figure 1-4 It can be seen that an engine intelligent thermal management system includes

[0059] Radiator, water pump, fan, cooling water jacket and cooling system temperature sensor;

[0060] The cooling system temperature sensor includes a cooling system sensor including an engine coolant temperature sensor, an intercooler intake air temperature sensor, and a torque converter oil temperature sensor; the engine coolant temperature sensor includes a first temperature sensor set on the engine body or on the cooling pipeline sensor and the second temperature sensor arranged on the radiator of the engine; the intercooler intake air temperature sensor includes three sensors arranged on the intercooler body and the fourth sensor arranged on the air intake pipeline of the engine, and also includes ambient temperature sensor and barometric pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com